Discover the appearance, function, and repair methods for boat transoms

While hulls and sterns are common knowledge in boating, understanding transoms is equally crucial. Situated at the stern, the transom serves as a pivotal structural element. Navigating through boating terminology can be daunting, but fear not; we're here to demystify transoms and their significance. Furthermore, we'll equip you with essential knowledge on identifying transom damage and executing necessary repairs to ensure safe boating.

Essential Insights

- A transom, positioned at the rear of a boat, provides a sturdy foundation for outboard motors, reinforcing the vessel.

- Prolonged exposure to motor stress can result in cracks in the transom, leading to water infiltration and subsequent rot.

- The most effective approach to rectify transom damage is through replacement, as water-induced degradation compromises its structural integrity.

- To maintain your transom's health, conduct regular inspections for signs of damage such as cracks and deteriorating seals. Consult a professional if moisture intrusion is suspected.

Guiding Steps

Understanding the Transom

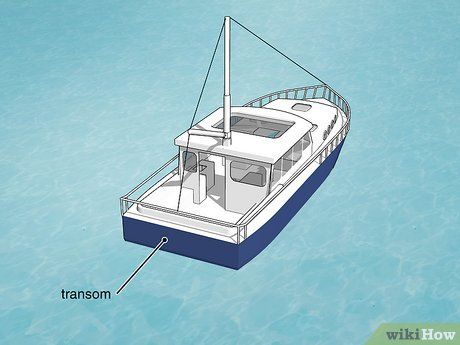

The transom, situated at the rear of the vessel, stands as a flat, vertical structure. Typically rectangular, it occupies the extremity of the boat, often serving as a defining boundary. Serving as a mounting point for motors, it's easily identifiable.

- Many boat owners opt to display their boat's name on the transom, aiding in easy identification.

- While transoms and sterns are frequently conflated, they denote distinct entities; the stern signifies a direction, while the transom denotes a structural component of the boat.

- Transoms manifest in various configurations, influenced by boat type and size, ranging from rounded to square. Additionally, they may exhibit varying inclinations, ascending or descending.

Utilizing the Transom

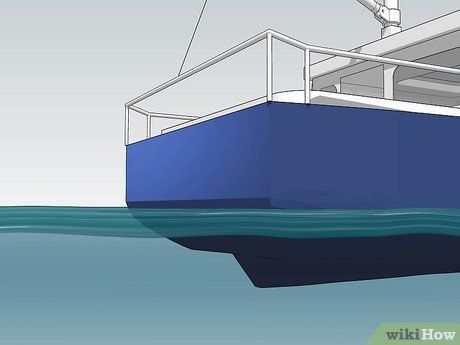

Fortifying the Boat's Rear As a fundamental structural element, the transom plays a pivotal role in safeguarding and reinforcing the boat's rear section. Primarily, it functions as a barricade, thwarting water ingress.

- Furthermore, the robustness of the transom aids in absorbing the energy generated by the motor, particularly relevant for motorized vessels.

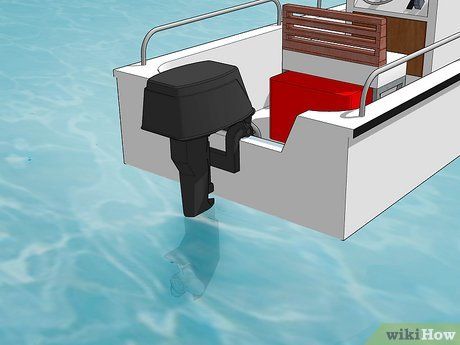

Accommodating Outboard Motors Recreational boats such as fishing vessels, bowriders, and consoles typically house motors for propulsion. The transom serves as a robust platform capable of withstanding the motor's power demands.

- The dimensions of the transom are often dictated by the number of motors installed on the vessel. Vessels equipped with multiple motors exert significant stress on the transom, necessitating increased thickness for reinforcement.

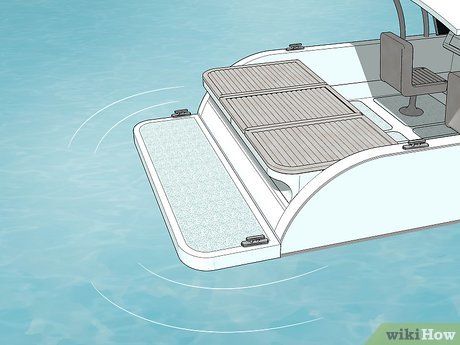

Facilitates Installation of Boating Accessories The structural integrity of the transom renders it an ideal location for mounting ladders, rear doors, and swim platforms on recreational boats. This provision offers passengers convenient access to and from the vessel's rear section.

Understanding Transom Damage

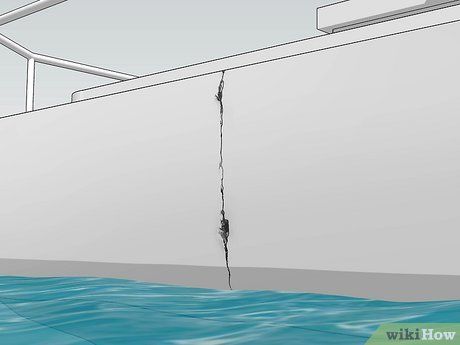

Signs of transom damage include cracks and compromised sealing, permitting water infiltration. Persistent motor stress and the transom's role in supporting the boat's rear can induce crack formation. Deterioration of sealants and bolts exacerbates water ingress, leading to transom rot. Given its pivotal role in vessel stability, water intrusion poses significant hazards.

- Hull damage can also impact the transom. Scraping the boat's underside in shallow waters or colliding with debris at high speeds may result in transom cracks.

Transom Repair: Is It Possible?

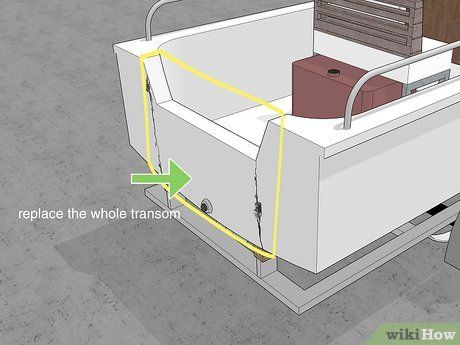

Opting for transom replacement is the most effective repair method. Once water infiltration initiates transom decay, structural integrity is compromised beyond repair. Even if drying is feasible, the transom's functionality is irreversibly compromised.

- Professional transom replacement typically incurs costs ranging from $1,500 to $5,000, contingent upon boat size. While the expense may seem steep, ensuring a sound transom is paramount for safe boating.

Replacing your transom independently is feasible but poses significant challenges. This typically entails removing deteriorated wood and fiberglass exterior, crafting a 1.5-inch (3 cm) thick marine plywood to match the transom's shape, and affixing it using resin. Subsequently, applying fiberglass over the plywood completes the restoration process.

Ensuring Transom Longevity

Regularly inspect your transom for any indications of damage. Prompt detection of transom issues is imperative to prevent exacerbation. After each boating excursion, assess the transom for cracks, leaks, or deteriorating seals around fasteners, as well as any loose fittings, bolts, or screws.

Identifying Moisture Intrusion in Your Transom If there are suspicions of transom leakage, consulting a professional for moisture analysis is advisable. Alternatively, a simple diagnostic involves tapping the transom; a hollow sound may suggest rot.

- Rust stains surrounding screws and bolts, warping, and fissures are additional indicators of transom decay.

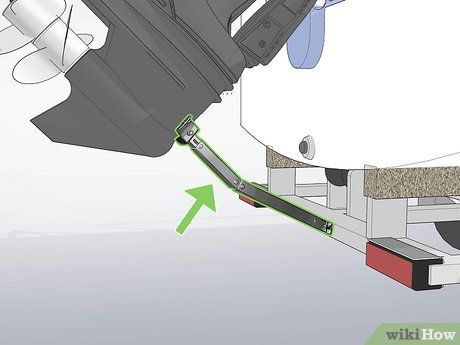

Safe Travels: Protecting Your Transom While transporting your boat, safeguarding the transom from road-induced damage is crucial. Utilizing a transom saver, a small bar affixed to the trailer, elevates the boat's bottom, alleviating pressure on the transom and shielding it from potential harm during transit.