Choosing the correct size of copper tubing is a crucial requirement to ensure the proper installation of an air conditioner. Selecting the right size of tubing will:

- Ensure the cooling efficiency of the unit: The size of the copper tubing needs to match the capacity of the air conditioner. An undersized tubing cannot ensure sufficient refrigerant flow to effectively cool the space. Conversely, an oversized tubing will create an unbalanced system, leading to energy wastage and failure to achieve maximum efficiency.

- Maintain durability and stability for the unit: The size of the copper tubing also affects the durability and stability of the air conditioning system. If the size is too small, the pressure and flow rate of the refrigerant can cause excessive pressure and damage to the tubing. On the other hand, oversized tubing can result in temperature differentials and heat loss due to the large surface area, reducing system stability.

- Ensure warranty coverage when purchasing genuine products: Incorrect installation of copper tubing leading to unit malfunctions may result in warranty rejection by manufacturers. Therefore, it is essential to carefully consider and verify the choice of copper tubing during air conditioner installation.

Copper tubes for air conditioners

2. How much copper tubing does a 2HP air conditioner use? Standards for the size of air conditioner copper tubing

2.1. Standard diameter sizes of copper tubing

In an air conditioning system, copper tubing consists of two directions: the inlet tube connects from the condenser to the evaporator, while the outlet tube connects from the evaporator to the condenser. Typically, the inlet tube is smaller in size compared to the outlet tube. For information on how much copper tubing a 2HP air conditioner uses, refer to the table below:

| Inlet Tube Diameter (From condenser to evaporator) | Outlet Tube Diameter (From evaporator to condenser) | |

| Copper tube for 1.0HP air conditioner | 6mm | 10mm |

| Copper tube for 1.5HP air conditioner | 6mm | 10mm or 12mm |

| Copper tube for 2.0HP air conditioner | 8mm | 12mm |

| Copper tube for 2.5HP air conditioner | 8mm | 12mm or 16mm |

Additionally, for air conditioners using R22 refrigerant, the thickness of the copper tubing needs to be ensured at 0.51 - 0.61mm. For air conditioners using R410A, R32 refrigerants, the standard thickness of the copper tubing is a minimum of 0.61mm.

2.2. Length of copper tubing between evaporator and condenser

In addition to diameter, the length of copper tubing between the evaporator and condenser also needs to meet the manufacturer's requirements. Typically, the minimum length of copper tubing is about 3m, and the maximum length is about 15 - 20m. The optimal length for air conditioning operation is typically between 3 - 7m (depending on the manufacturer).

You need to ensure the length of copper tubing between the condenser and evaporator is because:

- If the copper tubing is too short, it may lead to gas not returning to the compressor in time. This can result in blockages in the tubing and some internal damage to the unit.

- If the copper tubing is too long, it may prevent the unit from cooling quickly.

- Additionally, if you install copper tubing with a length outside the manufacturer's specified range, warranty claims may be rejected if the unit malfunctions.

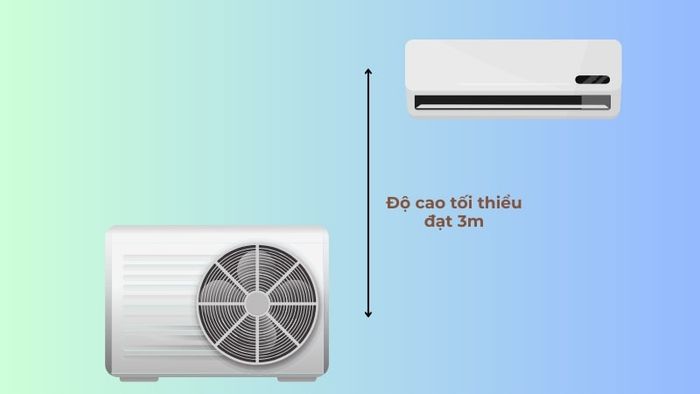

2.3. Height Difference between Evaporator and Condenser Units

The final factor to consider when installing an air conditioner is the height difference between the condenser and evaporator units. This height difference needs to be within the manufacturer's allowable limits and depends on the length of the copper tubing. For information on the height difference of each unit, you can refer to the technical specifications section.

Height Difference between Evaporator and Condenser Units

3. Standards for Copper Tubing Sizes of Some Popular Air Conditioner Brands

As mentioned, each air conditioner has different standards for copper tubing sizes. Therefore, you should carefully read the accompanying documentation to choose the appropriate tubing. Here are the size standards for copper tubing of some popular air conditioner brands on the current market for your reference:

| Air Conditioner Brand | Inverter Air Conditioner | Non-Inverter Air Conditioner |

|---|---|---|

| Panasonic Air Conditioner | TS Series: 1 HP uses 6/10 tubing 1.5HP uses 6/12.7 tubing 2 HP uses 6/12.7 tubing (for M-N-P codes). 2014 date Q models use 6/16 tubing | KC / C Series: 1 HP uses 6/10 tubing 1.5HP uses 6/12.7 tubing 2 HP uses 6/12.7 tubing. For 2 HP 2014 date QKH suffix models use 6/16 tubing |

| Daikin Air Conditioner | FTKZ, FTKY, FTKB Series: 1 HP uses 6/10 tubing 1.5HP uses 6/10 tubing 2 HP uses 6/12 tubing FTKY Series: 2.5 HP uses 6/12 tubing 3 HP uses 6/16 tubing | ATF Series: 1 HP uses 6/10 tubing 1.5HP uses 6/12 tubing |

| Toshiba Air Conditioner | KCVPG-V, KCVG-V Series: 1 HP uses 6/10 tubing 1.5HP uses 6/10 tubing 2 HP uses 6/12 tubing | KSG-V Series: 1 HP uses 6/10 tubing 1.5HP uses 6/12 tubing 2 HP uses 6/12 tubing |

| Sharp Air Conditioner | 1 HP uses 6/10 tubing 1.5HP uses 6/12 tubing | 1 HP uses 6/10 tubing 1.5HP uses 6/12 tubing 2 HP uses 6/12 tubing |

| Fujitsu Air Conditioner | 1 HP uses 6/10 tubing 1.5HP uses 6/10 tubing 2 HP uses 6/12.7 tubing | 1 HP uses 6/10 tubing 1.5HP uses 6/12.7 tubing 2 HP uses 6/12.7 tubing |

Hopefully, the article above has helped you answer the question 'How much copper tubing does a 2HP air conditioner use?'. It also helps you understand more about the size standards when choosing copper tubing for air conditioners. Copper tubing size directly affects the efficiency of air conditioner operation, so you should adhere to the manufacturer's requirements for stable and durable operation.

Explore some top-selling air conditioner models at Mytour Supermarket: