At some stage of your cheesemaking adventure, you'll find yourself needing a cheese press. However, before rushing to the big online marketplace to purchase one, it's essential to understand a few key points about cheese presses to ensure you choose the right one. (Pro tip: I couldn’t locate a single one on Amazon that matched the standard.)

What Exactly is a Cheese Press?

All cheesemaking processes begin by letting the milk curdle into soft, fluffy cheese clumps that resemble tofu. How we handle those curds depends on the type of cheese we aim to make. For hard cheeses, these curds need to bond together into a compact cheese wheel, and a cheese press serves as the tool that brings them together.

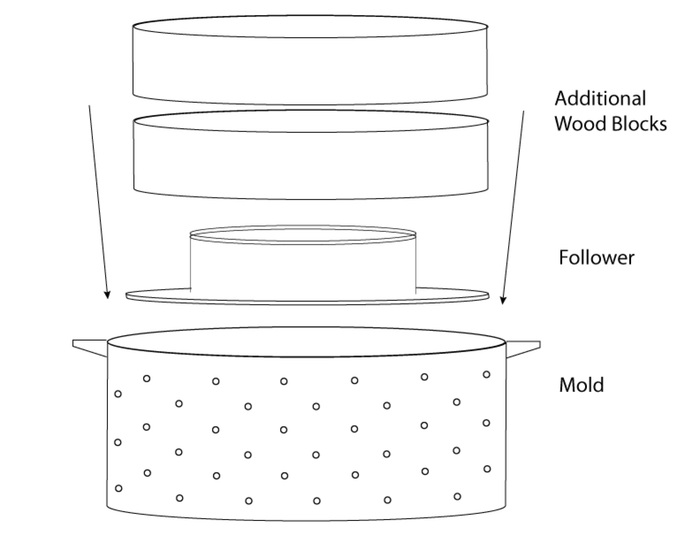

The curds are placed in a cheese mold, along with a follower—a flat piece that fits inside the mold to keep everything level. Then, we apply pressure using the press.

If it were as simple as piling on the heaviest weight, cheesemaking would be a breeze. However, the recipes you'll follow guide you to start with a light weight and gradually add more. This is crucial for allowing the whey to separate from the curds. Cheese molds are designed with holes for this purpose. A good press should be capable of applying weight while measuring how much is added. That alone disqualified around 90% of cheese presses on Amazon.

Your press must also accommodate the molds inside, so consider the sizes of the cheeses you plan to make and ensure the press provides ample room for the corresponding molds. (This eliminated the last press on Amazon, as it only supports smaller molds.)

Exploring the Various Types of Cheese Presses

To summarize: A high-quality press allows you to apply weight onto the cheese mold, tracks the weight you've added, ensures whey drainage, and fits the cheese molds you own. I've come across three distinct types of presses in my experience.

The Dutch press features a large lever on which you place the weight, with the other end of the lever applying pressure to the cheese. These presses are typically made of wood, and you can purchase them from various suppliers in the United States.

The second type of press uses springs to generate the required pressure. Strong springs are positioned between two wooden pieces, held in place with wing nuts. Instead of adding physical weights, you simply turn the wing nuts to replicate the pressure that would be applied by those weights. These presses are often made from plastic, steel, or wood.

The final style is a simple press made from two sheets of wood, steel threaded dowels, and wing nuts. It resembles the spring-loaded press but lacks springs. You place an actual weight on top and tighten the wing nuts progressively. These are usually constructed from pressed or inexpensive wood, which often appears flimsy. Although I haven’t used them myself, I’m skeptical about their effectiveness due to the flexible wood, which could lead to tipping issues. Still, they are affordable, so they might be worth experimenting with.

Can’t I just place something heavy on top of the cheese?

Believe me, I've tried—especially when I have multiple cheeses needing pressing at once. The problem is this: Regardless of what you use—books, weights, bags of clay—the cheese inevitably becomes unbalanced. The bottom of the cheese is a mass of unstable, gooey curd, and uneven pressure can cause the whole setup to collapse, resulting in uneven cheese and a cleanup mess. I've woken up to a stack of books or weights falling more times than I can count.

The great part? You can construct your own press at a fraction of the cost of those sold commercially, and it will outperform anything you can buy on Amazon.

A Guide to Crafting Your Own Cheese Press

I designed a spring-loaded press on my own, and it was quite straightforward. You can scale it to any size (my first attempt was too small), but the basic structure remains unchanged.

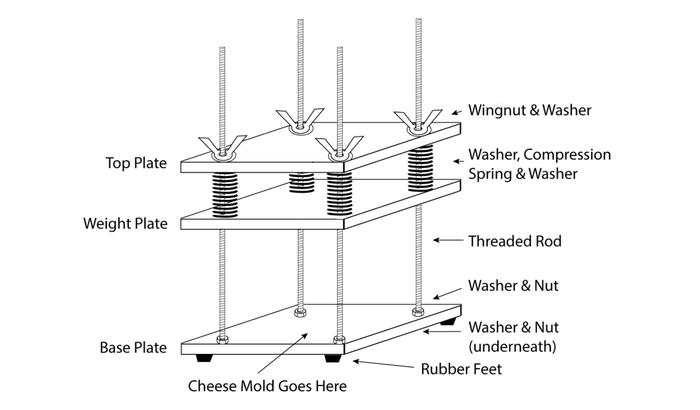

If possible, opt for a good-quality hardwood, as you won’t need much of it. You'll have three matching wooden plates: the base, the weight plate, and the top plate. Two or four metal threaded rods will run from the corners, passing through all of the plates to align them. They will be secured with nuts and washers under the bottom plate.

Heavy-duty springs will be placed between the weight plate and top plate, with wing nuts tightening the rods to the top plate. The diameter of the rods, and consequently the springs, should match the size of your press, but the press must be capable of exerting anywhere between five and 50 pounds of pressure.

Now, it’s simply a matter of assembling everything. You can add as much style to your press as you wish, but it's not a requirement.

Here’s what you’ll need:

3 pieces of hardwood, cut to the size you’ve chosen for your press

2 or 4 threaded rods (If your press is under 8 inches wide, two should suffice. The diameter is outlined below.)

2 or 4 compression springs that are slightly larger in diameter than your threaded rods

2 or 4 wingnuts

4 nuts

8 or 16 washers

A sheet of paper

50 pounds of weight (More details below.)

Rubber feet (optional)

Begin by figuring out the dimensions you need. Take your largest mold for hard cheese and add three inches to each side. This extra space is necessary for the threaded rods, which should be positioned at least 1-1/2 inches in from the wood’s edges.

Cut the plates to the desired size. While it's not required, you can use a router or sandpaper to smooth out the edges and corners. Don’t forget to treat the wood with food-safe wood oil.

Now, you’ll need to drill holes into all three plates. It’s helpful to make a paper template to ensure the rods align perfectly in all plates. A hand drill will suffice for this task. The hole size depends on the diameter of the threaded rod you selected. For smaller presses, any rod larger than ⅜-inch will be strong enough, but for larger presses, you may opt for ½ or ¾ inch rods. Your local hardware store can cut the rods to a length of 18 inches.

Secure the rods to the baseplate using washers and nuts. Then, thread on the weight plate, followed by the compression springs, top plate, washers, and wing nuts. You're nearly finished, but we still need to create a gauge to measure the pressure on the springs.

How to calibrate your newly constructed cheese press

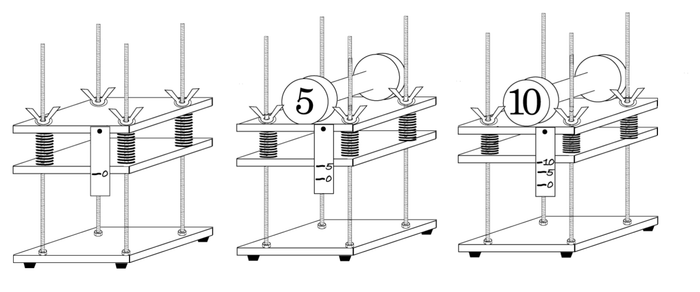

To begin, you'll need a scale and weights (or other objects weighing about ten pounds each). Take a strip of paper that's an inch longer than the space between the weight plate and the top plate. Secure it to the side of the top plate with a nail, and make a mark on the paper where it meets the bottom of the weight plate. Label this spot with “0,” indicating there is no weight applied yet.

Next, place a five-pound weight on top of the top plate. As the top plate moves closer to the weight plate, mark the paper again where it touches the bottom of the weight plate, and write “5” next to it, showing five pounds of pressure. Repeat the process until you have markings for 0, 5, 10, 20, 30, 40, and 50 pounds. This helps you accurately gauge the pressure being applied to your cheeses, making additional weights unnecessary.

You now have a fully functional cheese press! You can enhance it by adding rubber feet to prevent movement. Laminating the paper with the weight markings is a good idea, or you can use clear packing tape as a substitute if lamination isn't possible. This step ensures the paper stays clean and intact, even if it gets wet.

How to Use Your New Cheese Press

Place your cheese press on a rimmed baking sheet. Ensure your cheese mold has a follower inside it. Center the mold within the cheese press, positioning it between the base plate and the weight plate. Carefully set the weight plate on top of the follower, and use the wing nuts to move the top plate closer to the weight plate, aligning it with the mark on the paper to the desired amount of pressure.

The rimmed baking sheet will catch any expelled whey. When it's time to flip the cheese, simply push the mold out of the press and reset it for the next step.

In some instances, the molds may be tall enough that the follower sits inside the mold, lower than the mold's rim. In these situations, you'll require a wooden follower—sanitized blocks of wood that sit on top of the follower, providing a surface for the weight plate to press against. These wooden blocks should match the follower's size as closely as possible to ensure even pressure on the cheese, resulting in the most flavorful and aesthetically pleasing homemade cheese.