Connecting wires is the process of linking two electrical cables to allow a continuous flow of electricity. Before starting, it's important to disconnect the power and strip the insulation from the wires. There are various methods for connecting wires depending on the situation, such as using a connector cap for thin wires, or opting for a connector sleeve if you're working with wires that have six or more strands. Afterward, simply use electrical tape or heat shrink tubing to protect the connection, and the wires will be ready for use.

Steps

Strip the wires before connecting them

Turn off the power to the wires. Disconnect the device you're working on (if possible). If the wires are inside walls or the plug cannot be removed, switch off the circuit breaker in the area you're working to avoid electrical shocks during the connection process.

- If it's not possible to disconnect the power, stop the wiring connection immediately to prevent any dangerous accidents.

Strip approximately 2.5 cm of insulation from each wire's end. Choose a hole on the wire stripper that is 1-2 sizes smaller than the wire you need to strip. Insert the wire into the hole and pull the stripper towards the wire’s end to completely remove the insulation. Repeat this process on the other end of the wire.

- Wire strippers are available at local electrical stores.

- For bare wires, you can skip this step.

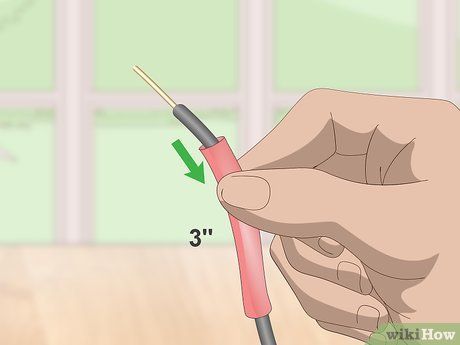

Cut a piece of heat shrink tubing approximately 7.6 cm long and slide it onto one of the wires you need to connect. This tubing, made of plastic, shrinks when exposed to heat. Slide the tubing onto the wire before connecting so you can easily cover the joint afterward.

- If you're using a connector cap, you don't need heat shrink tubing.

- Heat shrink tubing can be found at local electrical stores.

Tip: Heat shrink tubing comes in various colors. Choose a color that matches the current plastic coating on your wire if you want the connection to look more aesthetically pleasing.

Use a twist-on wire connector

Hold the two wire ends so that they touch each other. Position the two bare wire ends side by side. Do not twist or wind the wires together, as this will prevent them from being securely attached to the twist-on connector.

Place the twist-on connector on both wire ends and twist clockwise. Place the connector on both wire ends and start twisting clockwise. Continue twisting for about 5 seconds until the wires are twisted and wound inside the connector. Gently pull on both wire ends to check if the connection is secure. If not, twist the connector tighter.

- The connector contains a spring, so the more you twist, the tighter the connector will grip the wires.

- Twist-on connectors are available at local electrical or hardware stores.

- If needed, strip more insulation from the wires to continue twisting the connector.

Tip: You can easily remove the twist-on connector by twisting it counterclockwise. Remove the connector if you need to change the wires or the connection method.

Wrap electrical tape around the connector and the exposed wire ends. Wrap black electrical tape tightly around the base of the connector to completely cover the joint. Be sure to wrap it securely to minimize the chances of the wires being exposed. Once finished, use scissors or a utility knife to cut off any excess tape.

- If you're connecting multiple wires, consider using different colored tapes to mark the different connections.

Attach a wire connector sleeve

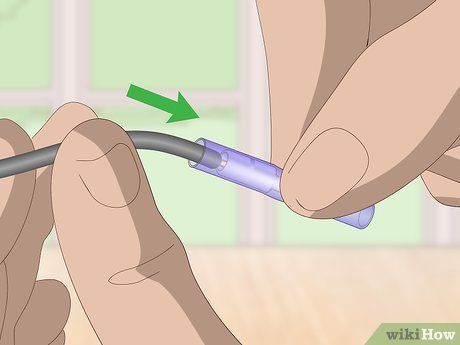

Insert the exposed wire end into the wire connector sleeve. A wire connector sleeve is a small tube with two openings, each designed to connect one wire. Take one wire end and slide it into one side of the sleeve. Push the wire until it touches the joint inside the connector.

- Wire connector sleeves are available at local electrical or hardware stores.

- This method is suitable for safely connecting large gauge wires.

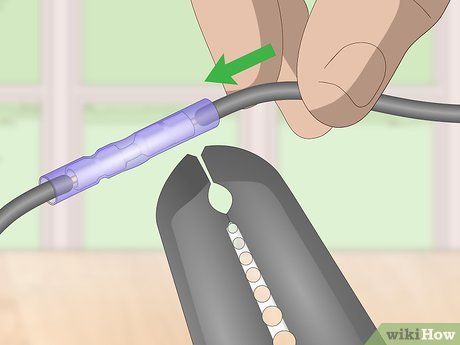

Use crimping pliers to crimp the connector about 1/4 inch from the end of the connector. Select the appropriate hole on the crimping pliers based on the size of the connector. Position the pliers about 0.6–1.3 cm from the connector’s end. Squeeze the handles of the pliers completely to firmly press the wire into the connector.

- Avoid choosing a hole that is too small, as this could cut through the wire.

- There are crimping wire strippers available on the market that combine both wire stripping and crimping functions, saving you from having to purchase multiple tools.

Tip: You should select a crimp hole that is slightly larger than the connector’s end to ensure the wire's core is pressed tightly against the insulation.

Insert the remaining wire into the other side of the connector and crimp it. Repeat the previous steps for the second wire. When inserting the second wire, make sure both wire ends make contact inside the connector. Use the crimping pliers to securely fasten the second wire.

- Some connectors are transparent, allowing you to verify that the wire ends are touching inside.

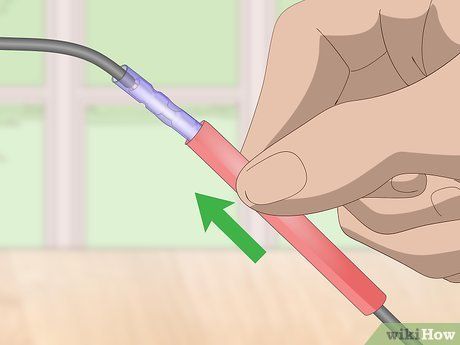

Slide heat shrink tubing over the connector to fully cover it. Pull the tubing from one of the wires and slide it over the connector. If the tubing is too loose or slips off the connector, use the crimping pliers to hold the tubing in place.

- If you forgot to slide the heat shrink tubing onto the wire before connecting, you can use electrical tape to wrap around the connector and exposed wires.

Heat the tubing using a heat gun. Turn on the heat gun and direct the hot air toward the tubing. Rotate the wire in your hand to ensure the tubing shrinks evenly around the connection, providing insulation similar to the original coating.

- If you don’t have a heat gun, you can use a match or lighter to shrink the tubing. Be careful not to let the flame touch the wire or tubing, as this could cause the plastic to melt.

Connecting wires like a professional

Bend both exposed wire ends into a 90-degree angle. Use your fingers or needle-nose pliers to form each wire end into an 'L' shape. Ensure each side of the right angle is approximately 1.3 cm long, providing enough length for the wires to twist together.

Hook the two wire ends so that the right angles touch each other. Place one wire on top of the other, aligning the inverted 'L' end with the upward-facing end of the other wire. The right angles of both wire ends should make contact.

Wrap the upward-facing wire around the wire at a right angle. Tightly wrap the upward-facing wire around the straight portion of the other wire. Ensure the twist is firm to create a solid connection. Aim for at least three complete twists if possible. Repeat the process for the other wire end.

- If you find it difficult to twist the wire by hand, use needle-nose pliers.

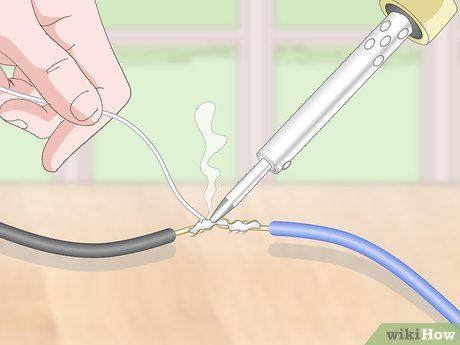

Solder the joints together to secure them. Use your dominant hand to heat the soldering iron and bring it close to the joints. With your other hand, hold a silver alloy soldering wire next to the soldering tip. Heat the alloy and allow it to flow into the joint between the wires, ensuring the solder covers the entire connection.

- Note: Be careful not to touch the tip of the soldering iron with your bare hand as it can burn you.

- Place a cloth or scrap wood underneath your workspace to protect the surface in case any molten solder drips.

Slide the heat shrink tubing from one of the wires to cover the solder joint. Move the tubing to fully cover the connection, ensuring no exposed wire is visible. If the tubing slips off, use a crimping tool to secure it onto the solder joint.

- If you don't have heat shrink tubing, wrap the joint with electrical tape instead.

Use a heat gun to shrink the tubing. Turn on the heat gun and direct the heat toward the heat shrink tubing. While heating, rotate the wire to ensure the tubing shrinks evenly and snugly around the joint. Continue applying heat until the tubing fits tightly like the original insulation.

- If you don’t have a heat gun, you can use a lighter or a match.

Warning

- Make sure that all wires are disconnected from the power source before proceeding.

- Do not touch the hot tip of the soldering iron.

Things You'll Need

Prepare the wires

- Wire stripper

- Heat shrink tubing

Use a twist-on wire connector

- Wire connector

- Electrical tape

Attach the wire connector

- Electrical connector

- Crimping tool

- Heat gun

Wiring professionally

- Soldering iron

- Heat gun