Untreated wood is particularly vulnerable to rotting, warping, or cracking. To extend the lifespan of your wood items, you can treat them with a waterproofing product. It's crucial to apply this protective layer to wood items that are regularly exposed to the elements, such as outdoor furniture. Additionally, waterproofing interior wood surfaces and kitchen counters is highly recommended.

Steps

Waterproofing with Oil

Choose the oil. Three commonly used oils for waterproofing wood are linseed oil, walnut oil, and tung oil. Tung oil is often sold in mixed forms within industrial products. Pure tung oil is more expensive than other oils and is typically reserved for smaller wooden items. Walnut oil is typically found alongside olive oil in food stores. However, due to its potential to cause allergies, walnut oil isn't widely used.

- Linseed oil is available in woodworking stores, often in natural or boiled forms. Boiled linseed oil contains metal components that are harmful and promote quick drying. While you can use this product for outdoor wood surfaces, avoid placing food directly on them.

- Linseed oil is also available in a form without harmful metal additives. Opt for natural linseed oil if you aim to create a safe coating for surfaces like kitchen counters.

Purchase the oil. Plan ahead and decide which wood surfaces you want to treat with oil. For larger surfaces like outdoor wooden floors, consider using outdoor paint or wood floor finishing products. Oil is more suited for smaller wooden items such as cutting boards, tables, kitchen counters, or baseball bats.

- Make a list of surfaces that need treatment to determine how much oil to purchase. The advantage of this method is that oil tends to last a long time.

- Buy the appropriate type of oil for your needs. It’s recommended to buy a larger container of oil to avoid running out during the process.

Mix the solution. You can create a high-quality mixture to coat and protect your wood surfaces by combining oil with turpentine and apple cider vinegar. Mix one part oil (tung, linseed, or walnut oil), one part turpentine, and half a part of apple cider vinegar. This mixture will help the oil adhere longer and create a better finish.

- Mix the ingredients in a metal container, such as a tea tin. Stir thoroughly.

- Although mixing isn’t mandatory, experienced woodworkers often recommend this method.

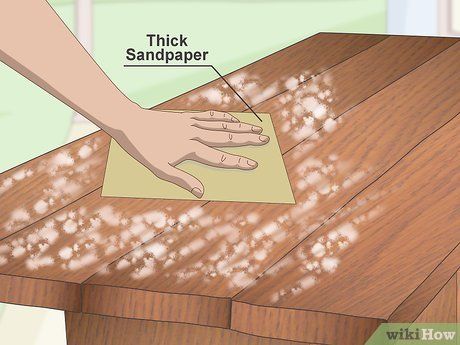

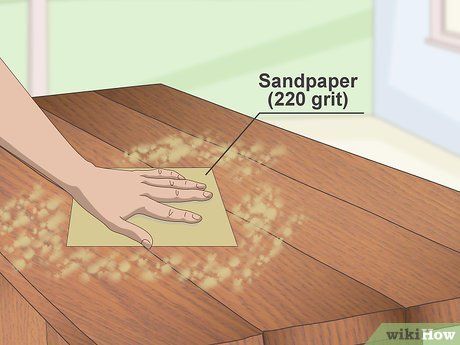

Prepare the wood surface before applying the oil. Imperfections on the wood surface will be more noticeable after the oil is applied. Oil or oil mixtures will accentuate the wood's color, so it's important to use coarse sandpaper or a metal file to smooth out imperfections. Sand or file the wood surface until it is smooth.

- Finish by sanding the entire surface with fine sandpaper (220 grit) to ensure the wood absorbs the oil better.

- Clean the surface of any debris using a dry cloth before applying the oil. The wood should be dry before oiling.

Prepare safety measures for yourself. Fold a lint-free cloth and gather some rags. Folding the cloth will remove any rough edges and prevent splinters from poking your hands when applying the oil. Wear thick rubber gloves when handling turpentine oil and other products containing minerals.

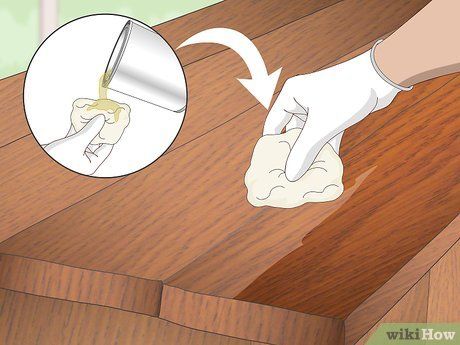

Apply the first coat of oil. Pour a small amount of oil onto the cloth. Do not pour the oil directly onto the wood. Apply the oil following the grain direction, moving from the inside out. Be careful not to touch the oil while waiting for it to soak into the wood. Try to create an even coat. Add more oil to the cloth rather than rubbing too hard, so the oil doesn’t drip from the cloth. Avoid leaving excess oil on the wood surface.

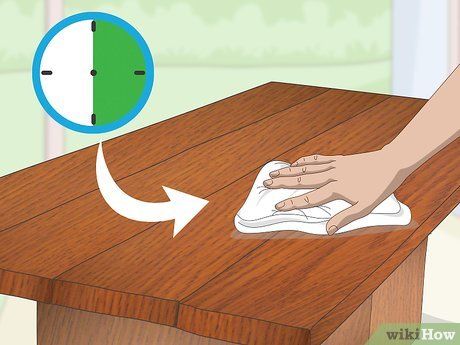

Let it dry. Wait for about 30 minutes for the oil to soak into the wood. Wipe the wood surface with a clean cloth to remove excess oil. Allow the wood to dry for 24 hours or until the oil is completely dry. Using oil for waterproofing will take longer than using surface coatings.

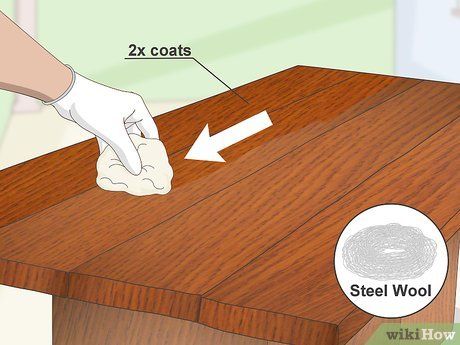

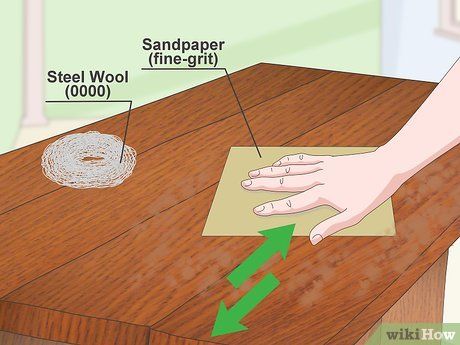

- Buff the wood surface with very fine steel wool (#0000).

Apply two more coats of oil. Apply another coat of oil to the wood. Repeat the drying process and buff with steel wool. Allow the wood to dry for several days to weeks before use. The wood is ready when you can smoothly glide your finger over the surface without resistance.

Waterproofing with Surface Coatings

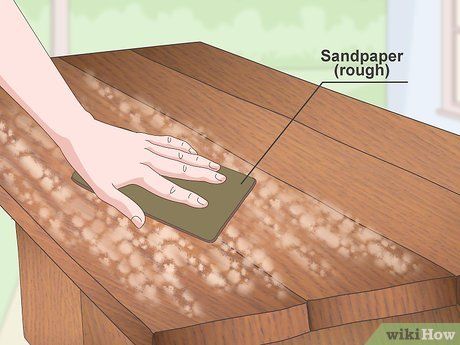

Preparation. You’ll need to remove any old coatings from the wood surface before applying a new layer of protective finish. Sand the wood surface before applying any surface coatings. This step will remove the previous layer, ensuring the waterproofing product can penetrate deeply. The surface coating method is best suited for wood that’s already finished, as oil-based paints may not absorb well into the wood.

- Use coarse sandpaper for areas that need more attention. Finish the sanding process with fine sandpaper to smooth out the surface.

Purchase a water-based wood surface coating product. These products are available at woodworking supply stores. Common surface coatings for wood include Water Seal (waterproofing) and Stain Sealer (surface finish). You can also purchase tinted coatings and sand the wood surface before applying.

- Surface coatings are often named according to the type of surface they treat. For example, you can find coatings for outdoor wood floors, fences, patios, decking, or interior wood surfaces.

- Buy a wood surface coating suitable for humid environments if your wood will be exposed to moisture, UV rays, or water.

- Check the product for instructions on use and drying time. Some products are applied with a spray tool.

- Purchase a spray applicator or a paintbrush to apply the coating to your wood surface.

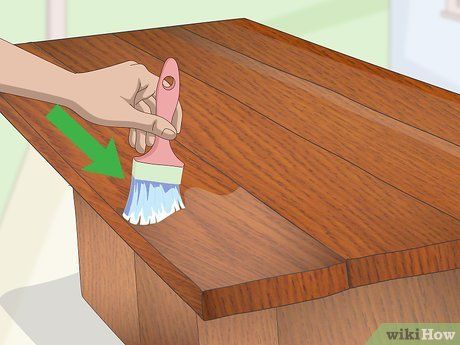

Apply a smooth, even coat. Prepare a paintbrush or spray applicator and aim to create an even surface coating. Ensure that the temperature and humidity are within the recommended levels as stated on the packaging to prevent the product from evaporating too quickly. It’s best to perform this task in a place with stable humidity, like a workshop.

- Make sure the wood surface is clean before applying the coating.

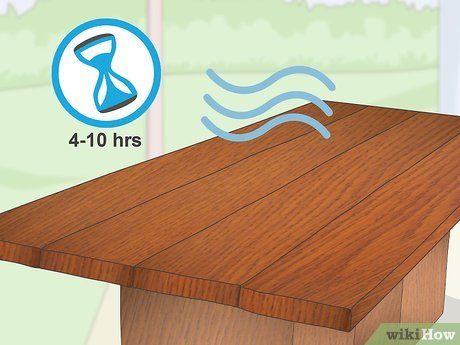

Allow the surface coating to dry. Check the instructions on the packaging for the recommended drying time. The drying process for this method will be faster than drying with oil. Many surface coatings typically take about 4-10 hours to dry.

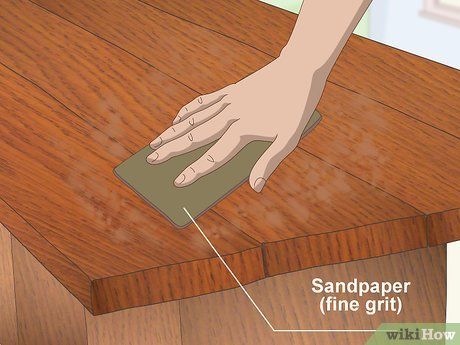

Smooth the first coat surface. Sand the wood surface with fine-grit sandpaper to improve the adhesion of the second coat, but only do this if instructed to do so. Perform this step once the first coat has fully dried.

- You can also use very fine steel wool (#0000) to smooth the first coat’s surface.

Apply the second and third coats. Softwoods typically require two to three coats, while hardwoods need only one. Softwoods are less expensive and are usually untreated. Common softwoods include cedar, pine, redwood, spruce, balsa, and cypress. Hardwoods are thicker and typically used for high-quality furniture and flooring. Popular hardwoods include oak, maple, mahogany, maple, and walnut.

Allow the wood to fully dry. Wait for several days for the wood to dry before use or placing furniture on it. When exposed to water, the wood surface will darken, and water will no longer pool but flow off the surface.

- Reapply the surface coating every few years to keep the wood durable.

Waterproofing with Paint

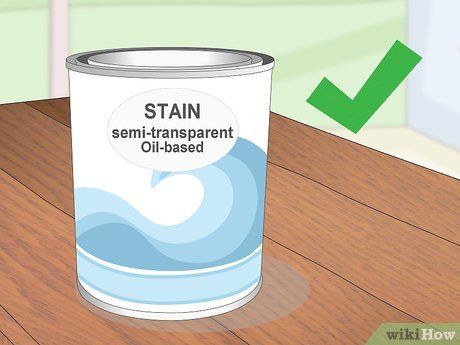

Choose an oil-based, semi-transparent paint. If you're treating outdoor wood products, select a paint designed for outdoor use. The lighter the paint color, the more oil it contains. Light-colored paints are ideal for indoor wood or wood not exposed to the elements.

- These products can be found at specialty woodworking stores.

Preparation. Imperfections on the wood surface will become more noticeable once the paint is applied. Additionally, the paint will enhance the wood's natural color. Therefore, use coarse sandpaper or a metal file to address imperfections. Sand or file the surface until it’s smooth.

- Finish this step by sanding the entire surface with fine sandpaper (220 grit) to help the paint adhere more evenly.

- Clean the surface of debris with a dry cloth before painting. The wood must be completely dry before you proceed with the next step.

Apply the first coat of paint. Use a paintbrush to apply the paint evenly. Cover the entire surface and then allow it to dry. Let the wood dry for four hours to a full day before applying the next coat of paint.

Remove excess paint. Sand the dried paint surface with fine sandpaper. Wipe the surface with a folded cloth before applying the second coat. It’s crucial that the wood surface is clean and dry before applying the next layer of paint.

Apply the second coat of paint. This coat will require more drying time. Make sure the paint dries thoroughly so that the waterproof oil can soak into the wood. Check the second coat after five hours of drying.

- The paint is dry if it no longer feels sticky when you touch the wood.

Apply the third and final coat. Repeat the same process when applying the final coats of paint. Be patient and ensure an even application throughout. Wait about three days to a week for the wood to dry before using it.

What You'll Need

Waterproofing with Oil

- Oil (walnut, linseed, or tung)

- Pine oil (optional)

- Sandpaper (coarse and fine grits)

- Lint-free cloths

- Rags

- Fine steel wool (#0000)

Waterproofing with Surface Coatings

- Wood surface coating product

- Paintbrush

- Spray paint tool (optional)

- 220-grit sandpaper

- Fine steel wool (#0000)

- Multiple cloths

Waterproofing with Paint

- Oil-based paint

- Paintbrush

- Sandpaper (coarse and fine)