Do you have a home project or craft that requires drilling through glass? You can use a standard electric drill with the right drill bit for the job. The key here is that the material you're drilling with must be harder than the glass.

Steps

Find the right tools

Identify the type of glass you want to drill. You can drill through wine bottles, aquariums, mirrors, glass tiles – in general, any type of glass. However, one important rule is never drill through tempered or safety glass.

- Tempered glass will shatter when it comes into contact with the drill bit. To identify tempered glass, check the four corners. If it is tempered, the manufacturer will have etched each corner.

- Another precaution: When using the drill, make sure you’re not wearing loose clothing or dangling accessories like necklaces, bracelets, or garments with long fringes. It’s essential to avoid wearing or carrying anything that could get caught in the power tool. Additionally, wearing safety goggles and gloves is highly recommended.

Buy or use an existing drill at home. You can use a drill that you already have at home; otherwise, you can purchase a standard electric drill from most tool stores.

- Drilling holes through glass doesn’t require a specialized drill – you just need the right drill bit.

- However, it’s important not to use the full power or the highest speed of the drill; otherwise, the glass may crack. Think of it like engraving on glass rather than drilling through it. Set the drill speed to the lowest setting. This will help slow down the drilling process.

Select the correct drill bit. You need to choose a drill bit specifically designed for drilling through glass. This is very important; you can’t just pick any drill bit. Ask a salesperson at a tool store to help you select the right one. Glass drill bits are fairly common, and you can also buy them online.

- Carbide drill bits, used for drilling glass and glass tiles, are also a good option. These bits have a spade-shaped design and can withstand the friction of drilling through glass or tiles.

- You can find carbide drill bits at tool stores. Just head to the drill bit section and ask a salesperson. However, a downside of cheap drill bits is that they wear out quickly and may even break.

Another option is to use diamond drill bits. These drill bits are specifically made for drilling through glass, sea glass, wine bottles, glass tiles, and other harder materials like marble and stone. Diamonds are harder than glass, making them the perfect material for drilling through tough substances.

- Diamond drill bits can be used for holes with a diameter of about 0.6 cm or larger. You can choose a round or tube-shaped drill bit. A diamond drill bit will create a smoother hole. Diamond bits have traditionally been used for drilling glass; one bit can drill multiple holes and rarely breaks if used properly.

- For very small holes, you can choose a small diamond drill bit with a hard, flat tip. There are many small-sized bits available, down to 0.75 mm.

- You can also purchase diamond hole saws. These require a self-starting rapid-change bit. These parts will fit onto the drill. Use the hole puncher on the drill to make the initial hole in the glass. Then attach the hole saw to the drill and place it over the hole you just created with the punch. Continue drilling through the hole.

Preparing to Drill

Place the glass material in a small box, if possible. You can use an ice cream box or a plastic tray. You definitely don’t want to drill through a table or similar surfaces.

- Place some old newspaper at the bottom of the box to prevent the drill from going through the box.

- Alternatively, you can place the glass on a hard, flat surface. If possible, you should place a rubber mat or other material underneath, but the glass must lie flat and be securely supported. In other words, don’t stand the glass upright when drilling or do anything similar.

- Always be cautious. Make sure you’re not drilling in a way that could damage furniture, and remember that the drill’s power cord should not be near water.

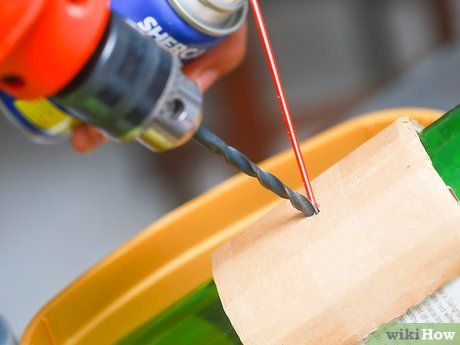

Attach a piece of cardboard or tape to the glass. This will prevent the drill bit from slipping when you start drilling. You can use a box lid for this purpose.

- Another method is to apply tape on both the inside and outside of the glass surface you intend to drill. This will protect the glass from breaking.

- Cut two pieces of tape. Arrange them in an 'X' shape at the point where you want to drill. Never drill a hole closer than 2 cm from the edge of the glass.

- Mark the spot where you want to drill the hole on the tape. This will help you identify the correct location when preparing to drill.

Drilling a hole

Start drilling at the lowest speed setting. It is recommended to drill slowly for harder materials; you can look up online charts that suggest drilling speeds for different materials, including glass.

- Attach a small drill bit to a variable-speed drill. Ensure it is tightly secured. It's best to begin with a 1/8" or 3/32" drill bit. You should first create a small depression on the glass.

- Then, remove the cardboard or tape and drill faster, at around 400 rpm. If you drill too quickly, the drill bit may cause burn marks around the hole. If necessary, you can switch to a larger drill bit to widen the initial hole. The first hole acts as a "guide hole" that will guide the larger bits you use until you're finished.

Reduce pressure and drilling speed as you approach the glass surface. When drilling glass, it is important to keep the drilling speed low to medium. As you get closer to penetrating the glass, you need to slow down even more, as this is when the glass is most likely to break.

- If you apply too much pressure, you could crack the glass. Make sure the drill bit is perpendicular to the surface of the glass to avoid chipping. If you're not familiar with this task, apply light pressure to avoid making any major mistakes.

- Another approach is to drill halfway through the front surface, then carefully flip the piece over and drill from the other side until the hole is complete.

Use a cooling agent to prevent the drill bit from overheating. This is crucial. Pour a small amount of oil or water on the drilling area. Water is the most common cooling agent for drill bits. You may need to apply more cooling if drilling tougher surfaces. The cooling agent will help keep the drill bit smooth and cool. If the glass becomes too hot, it may crack and break.

- You can use the cooling agent before and during the drilling process.

- Alternatively, you can pour some water into a bottle and drip it on the drilling area. The water will flow into and out of the hole as you drill, helping to cool the bit.

- You can also spray water around the drill bit to keep it lubricated. Be sure to stay cautious with electrical wires and water. Try filling a spray bottle with water and spraying it while drilling. If you notice white powder forming during the drilling process, apply more cooling agent and reduce the drilling speed.

- You can place a damp sponge under the glass while drilling as a cooling agent. Or you can apply water to the glass before starting to drill—by dripping water on the glass surface.

Tips

- Avoid using high speeds when drilling. Glass is very hard and has high friction, which can cause drill bits to wear out quickly.

- Using a hole puncher can help stabilize the drilling force.

- Start with smaller drill bits and gradually switch to larger ones to reduce pressure on the glass.

- Be aware that the drill bit might chip the edges of the hole on the back side of the glass; the hole on the front will be smoother.

- It's extremely important to always wear a ventilation mask. Dust from glass, also known as silica dust, can cause lung cancer, a disease known as silicosis.

- Keep the glass cool while drilling. This will help prevent it from breaking and the drill bit from breaking.

- While water is preferred, cutting oil can also be useful for drilling—but use it sparingly.

Warnings

- Glass is brittle and sharp. Be careful when handling it. Always wear gloves, a mask, and safety goggles when drilling holes.

- Glass shards can be hazardous to your eyes, so make sure to wear ANSI-approved safety goggles.

Things You’ll Need

- Drill with multiple speed settings

- Glass drill bit

- Stable working surface

- Adhesive tape

- Water container or spray bottle

- Safety goggles (ANSI standard): Any "ANSI" glasses will have the "Z87" mark on the frame.