Whether the fan blades are not rotating or the fan is producing excessive noise during operation, most electric fan issues revolve around insufficient lubrication and blocked air vents. To fix the majority of fan problems, you need to disassemble the fan, lubricate the rotating shaft and bearings, and clean the air vents as well as the motor casing. The fan repair process can become challenging if the issue lies with the motor (the fan makes no sound when turned on, and the blades do not spin even after cleaning and lubricating the shaft). Since this device is not overly expensive, it’s not worth spending time repairing the motor yourself; instead, simply purchase a new fan.

Disassemble the Fan

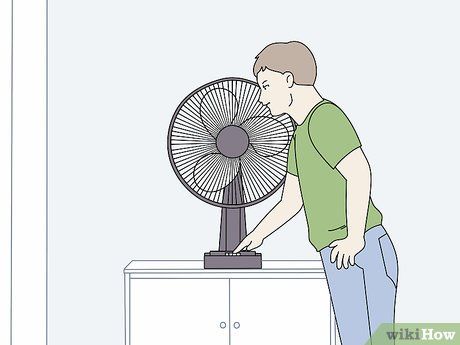

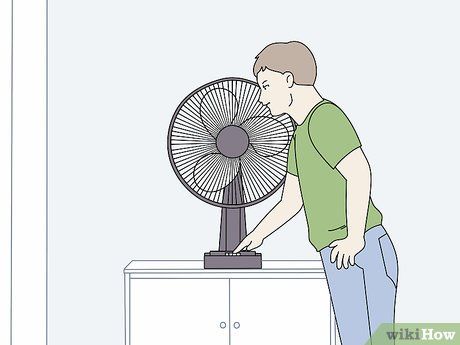

Turn on the fan to check if the motor is functioning. Plug it in and set the fan to the highest speed. If the blades spin, the motor is still working. If you hear no sound, place your ear close to the center of the casing behind the blades. Turn the fan off and on again, this time listening more carefully for the motor noise. If there’s a humming or vibrating sound, the motor is still operational.

- Test the fan in multiple outlets. The circuit breaker for the outlet might be off, preventing the fan from receiving power.

Tip: For most standing and desk fans, you don’t necessarily need to tinker around to test the motor. There’s a chance the motor is already faulty. If the motor isn’t working, you should consider buying a new fan. However, if you’re eager to give it a try, feel free to disassemble the fan and attempt repairs.

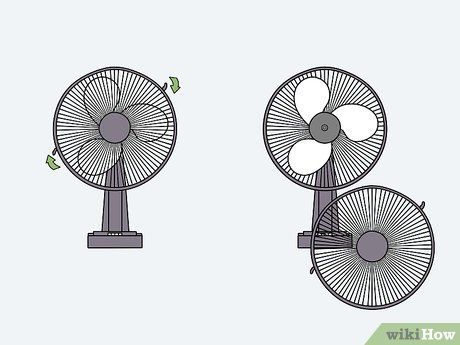

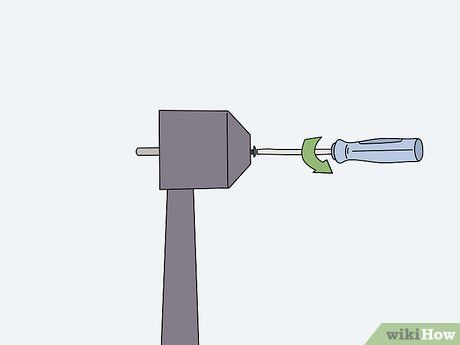

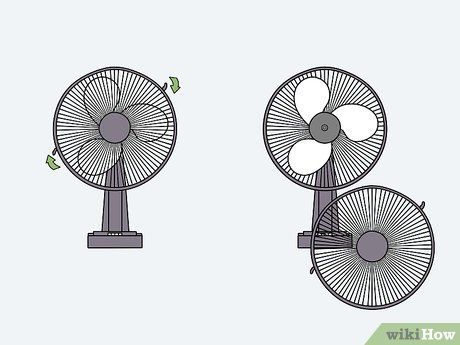

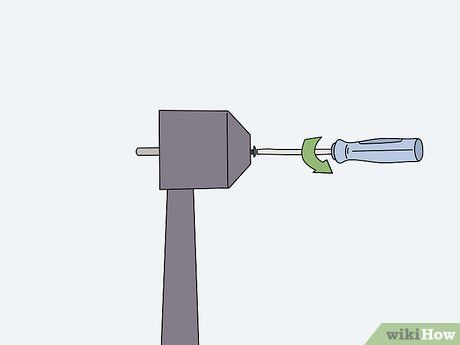

Unplug the fan and remove the protective cage or the shaft screw. Unplugging ensures the fan doesn’t suddenly start spinning while you’re working. Run your fingers around the edge of the protective cage to locate the clips holding the two halves together. If found, you can release the clips and remove the front cage. If no clips are visible, try rotating the central cap counterclockwise. If it loosens, continue twisting to detach the front cage covering the fan blades.

- The shaft is the metal rod between the fan blades and the motor housing.

- The cage is a plastic or metal component designed to protect the blades and prevent user injuries. On most fans, the two halves of the cage either clip together or are secured by a central cap.

- If you find screws holding the cage, use a screwdriver to remove them.

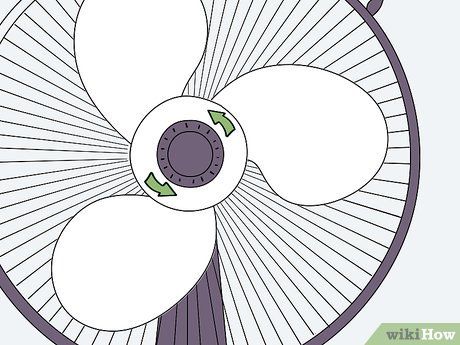

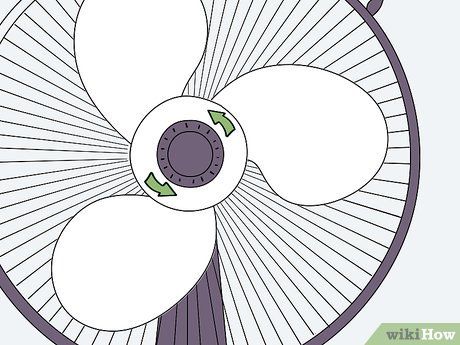

Rotate the fan blades or the central knob counterclockwise to remove them. Different fans have varying designs, but generally, the blades are secured by a small knob or the shaft itself. If the blades are held by a plastic knob, twist it counterclockwise to detach it, then slide the blades off. If there’s no knob, hold the shaft steady and twist the base of the blades to remove them.

- Depending on the fan model, there may be a side pin on the shaft to secure the blades. This pin usually slides back and forth to lock or unlock the blades.

Slide the rear half of the protective cage off the shaft. Remove any plastic or metal nuts located at the front of the rear cage. You may need to unscrew a few screws to access this part. Detach the nuts and slide the remaining protective cage off the shaft.

- If the blades are secured by a front plastic knob, there won’t be a rear nut, and vice versa. This knob or nut holds the blades in place on the shaft.

- If there’s a plastic cover or casing in front of the motor, unscrew it to remove it.

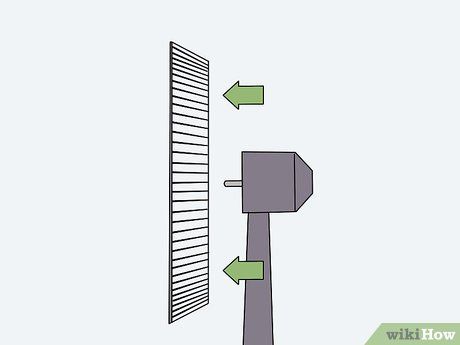

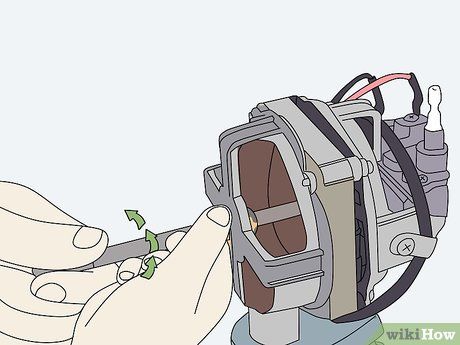

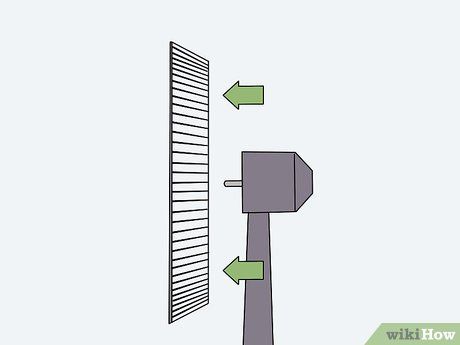

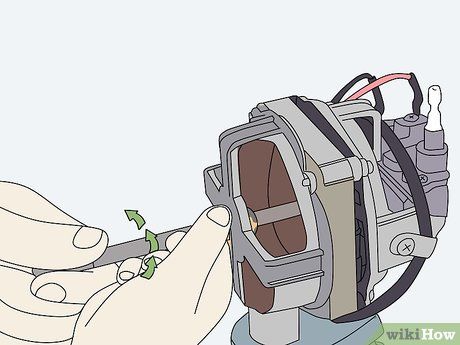

Turn the fan around to locate the screws at the back. Now that the shaft and the front of the motor are mostly exposed, rotate the fan to inspect the opposite side of the motor housing. Most fans have plastic ventilation holes to allow heat and air circulation for the motor. You’ll find screws at the back securing this part. Use a flathead or Phillips screwdriver to remove them. Set the screws aside and detach the motor housing.

- The motor housing should come off after removing the screws. If not, insert a flathead or Phillips screwdriver into the ventilation holes and gently pry the housing open.

- On some desk fans, the motor is typically located in the base. If the fan doesn’t have a bulky head behind the blades but has a wide base, unscrew the bolts underneath and remove the plastic cover.

Lubricate the Rotating Shaft

Manually rotate the front shaft of the fan to check if it spins. Turn the central shaft of the fan by hand. If the shaft feels stuck or stiff, it may be due to insufficient lubrication. Over time, the lubricant on the shaft diminishes as the blades rotate. You’ll need to reapply lubricant to resolve this issue.

- A dry or sticky shaft is one of the common reasons why fan blades stop spinning.

- If the shaft rotates smoothly without resistance, try turning the fan on to see if it spins. If not, the issue likely lies with the motor. In this case, purchasing a new fan is the easiest solution.

Loosen the nut or bolt at the end of the shaft. At the end of the shaft, there are usually 1-2 metal bolts securing the shaft to the fan frame. Use a wrench to loosen these bolts. You don’t need to remove them entirely—just create enough space to access and lubricate the shaft.

- If there are no nuts or bolts, skip this step.

- The nuts in this area of the fan can often be loosened by hand.

Apply lubricant to the front and back of the rotating shaft. Use a bottle of lubricant with a narrow nozzle for precision. Place a clean cloth underneath the shaft to catch any excess oil. Invert the lubricant bottle and direct the nozzle toward the area where the shaft meets the motor frame. Squeeze the bottle to apply oil to the front of the shaft. Continue lubricating beneath the bolts by rotating them into the oiled area. Repeat this process for the back of the motor frame to ensure both ends of the shaft are lubricated.

- You can use any type of lubricant. Fan-specific lubricants or general-purpose motor oils are available at most automotive or hardware stores.

- Technical lubricants are non-toxic and easy to clean with soap and water. However, you can wear rubber gloves if you prefer to avoid getting oil on your hands.

Warning: Use an appropriate amount of lubricant on the shaft surface and avoid letting oil drip into the motor. If excess oil leaks from the shaft, use a cloth to wipe it clean.

Rotate the shaft with one hand while tightening the bolts around the lubricated area with the other. Once the shaft has been oiled, you can reattach the bolts to their positions. Use your dominant hand to hold the shaft and the other hand to grip the bolt with a cloth. Slide the bolt back and forth through the lubricated area while rotating the main shaft. Repeat this process for the bolts on the opposite side of the shaft.

- This process ensures the oil penetrates the inner surfaces of the bolts. If the bolts are not lubricated, they can create friction that hinders the shaft's operation.

- You can also remove the bolts and oil them separately if desired.

Clean the engine and ventilation holes

Wipe away any dust behind the engine casing (if present). Rotate the fan and inspect the inside of the engine casing for dust. Use a microfiber cloth to clean any accumulated dust on the inner surface of the engine casing behind the fan.

- Poor ventilation systems can lead to dust buildup inside the engine casing. This can cause the fan to stop operating, especially in fans with temperature control features that automatically shut off the device when it overheats.

Warning: Do not use water to clean the engine area. If water seeps into the engine, it can cause electrical shorts or damage the fan.

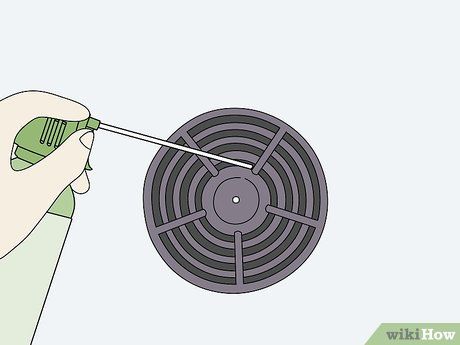

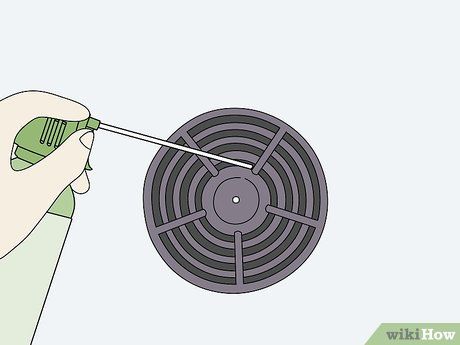

Use a can of compressed air to clean the plastic ventilation holes at the back of the fan. Remove the vent cover you unscrewed before lubricating the fan and place it away from the engine. Spray compressed air on both sides of the cover to blow dust out of hard-to-reach slots between the bars. Then, wipe it down with a dry cloth.

- If the ventilation holes are completely clogged with dust or debris, this could be the reason the fan is not operating properly.

- For a deeper clean, you can soak the vent cover in soapy water and let it air dry. However, this is usually unnecessary.

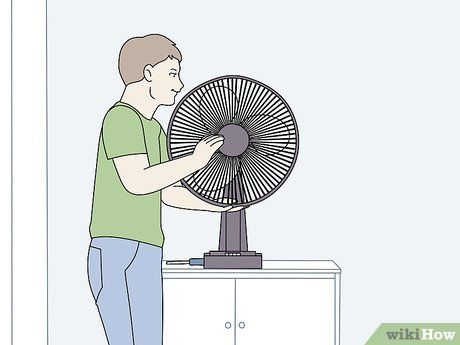

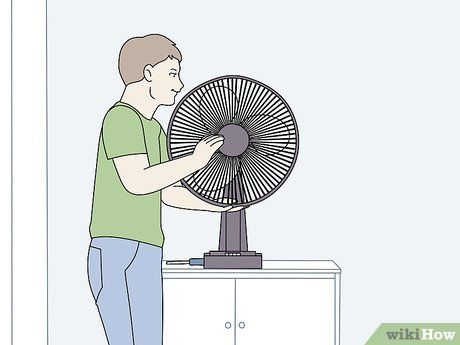

Plug in the fan and check if the main shaft rotates. Before reassembling the fan, plug it in and test whether the main shaft spins smoothly. If the shaft operates normally, you can proceed to reassemble the fan. If the shaft doesn't rotate or spins slowly, it's likely that the motor needs cleaning. However, this process can be quite complex, so if the fan is inexpensive, it may not be worth the extra effort.

- Many standing and desk fans are designed with non-removable motors, making cleaning and repairs extremely challenging.

Reassemble the fan by attaching the motor casing, bolts, and fan blades. This process is the reverse of disassembly. Attach the rear guard and tighten the nuts, then use a wrench to secure the bolts that hold the rotating shaft in place. Install the fan blades so the rear guard sits between the motor and the blades. Reattach the plastic vent cover to the back of the motor casing and tighten the screws. Fit the front guard to align with the rear guard.

- Turn on the fan. If the blades spin much slower than during the shaft test, the motor may be faulty. This indicates the motor is operating at too low a capacity to run the fan normally.

What You'll NeedDisassembling the Fan

Lubricate the Rotating Shaft

-

Fan Lubricating Oil

-

Wrench

-

Cloth or Towel

Clean the Motor and Ventilation Holes

-

Microfiber Cloth

-

Compressed Air Can

-

Screwdriver

-

Wrench