Towards the conclusion of 'Skyfall,' there's a moment when James Bond and M drive away from the city in a timeless 1960 Aston Martin DB5, the iconic silver car first introduced in 'Goldfinger' in 1965. Later—and this might be a spoiler—the car gets riddled with bullets and blown up by a helicopter.

If you’ve watched any movie in the last decade, you’re aware that this particular scene would have been fairly simple for the filmmakers to create. All they had to do was digitally add the explosion—or with that kind of budget, they could’ve just used one of the few remaining DB5s and destroyed it for real.

Instead, the filmmakers opted to 3D print detailed 1:3 scale models of the Aston Martin and blow them to smithereens, leaving the real cars safe for display in museums. Sound familiar? Think Iron Man’s suit, same technique.

Here are ten ways people are using 3D printers for practical purposes—and in some cases, making a significant impact on the world along the way.

10. Apparel

In the early stages of 3D printing, the objects produced were often large, bulky plastic items—like design prototypes, serving as visual guides before creating the final product. With more advanced technology, we're now able to print smaller, more precisely detailed objects. The 3D printing team at Shapeways embraced this and introduced printed nylon clothing, designed to fit the exact body dimensions of the person who orders it—truly the most personalized clothing in existence.

Their debut 3D printed clothing line is the N12 Bikini (N12 refers to Nylon 12, the material used). The bikini is created using an equation known as circle packing, meaning it’s made entirely of small, interconnected circles that an algorithm adjusts depending on the curve of the shape—larger curves require smaller circles. The entire design is based on a body scan to ensure the final product fits the wearer perfectly.

9. Guitars

Guitars—or at least their ancestors—have been crafted from wood since around the twelfth century. In more recent years, plastic has also been incorporated, but the fundamental process of construction remains the same. It’s subtractive, meaning material is removed to achieve the correct shape. You start with a large block of wood, carve it, and end up with a guitar part. This subtractive approach is typical in manufacturing.

In contrast, 3D printing follows an additive process—it builds up layer by layer, gradually forming the desired shape using material that eventually solidifies (similar to a hot glue gun creating a puddle of glue).

With this technique, virtually anything can be created—even a nearly perfect acoustic guitar shape. This guitar is a prime example, printed by Scott Summi, marking a world-first. Every part of the guitar was printed, excluding the neck and strings (even the metal components were printed), and the process took around two hours. Since 3D printed objects are based on a computer model, there’s no limit to how a guitar can be designed—this opens up endless creative possibilities.

8. Homes

Last year, Behrokh Khoshnevis, an engineering professor at the University of Southern California, delivered a TED talk where he explained how a full-sized house (25,000 sq. feet, or 2,320 sq. meters) could be 3D printed in under twenty hours, including plumbing and electrical wiring. This timeline seems almost unbelievable. Entire neighborhoods could be constructed in a month, and all it takes to create a completely different house is altering the computer’s design blueprint—no more cookie-cutter suburbs.

More significantly, this technology could be used to rebuild slum areas or provide rapid housing solutions for those displaced by natural disasters. To put it into perspective, had this technology been available when Haiti was hit by the 2010 earthquake, nearly everyone who lost their home would already be settled in a new one.

7. Camera Lenses

Photography is perhaps the last place you’d expect to see 3D printing emerge. A high-end camera can cost thousands of dollars, and the lenses that accompany them are just as expensive. There’s a good reason for this: photography, at its essence, is the capturing of light, and to get the best results, you need top-tier equipment. Lenses are particularly vital because they bend the light at the right angles to create a focal point, ensuring the image remains sharp and clear.

While 3D printed camera lenses aren’t yet on par with those crafted traditionally, they are advancing rapidly. This is partly thanks to platforms like Thingiverse, where users can upload design blueprints—making it possible for others to download and refine them. This camera lens is made from acrylic on a home printer and produces decent images. Higher-end 3D printers are already capable of printing glass items, so it likely won’t be long before you can print a glass lens at home that rivals commercial lenses—at a fraction of the cost.

6. Edible Creations

NASA has been using 3D printers to produce parts for their spacecraft for several years—a cool fact in itself. However, NASA is now pushing that concept in an entirely new direction; they’re currently in Phase One of a three-phase initiative to develop a method for printing food during long space missions.

The space program isn’t leading the charge in food printing—that credit goes to Andras Forgacs, CEO of Modern Meadows, who became the first person to consume a piece of printed meat earlier this year. The process of 3D printing food follows the same basic principles as any other object: simply swap the plastic with living cells, then build muscle tissue layer by layer.

By making that simple substitution, you effectively eliminate the myriad environmental issues associated with modern agriculture.

5. Creative Expression

Humans are extraordinary. Some aim to save the world, while others strive to inspire it. Art has been instrumental in advancing human intellect for centuries, and now, 3D printing offers another medium for artists to explore—and some of the results are truly awe-inspiring.

The sculpture above was created by Sophie Kahn, a photographer and sculptor who was drawn to 3D printing as a “post-photographic process”—a way to add another layer of creativity to a photo. Sophie Kahn is making waves in the art world, but she’s not alone—there are hundreds of others who have turned to 3D printing as a form of creative expression. It also helps that for struggling artists, the materials are far more affordable than traditional art supplies.

4. Prosthetics

In 2011, Richard Van As lost four of his fingers in a carpentry accident. Faced with an expensive prosthetic option costing around $10,000, Richard decided to build his own—using a 3D printer in his own home.

His creation, called the Robohand, features five fingers that close when he bends his wrist. After completing the hand, he uploaded the design blueprint online so others could replicate it. But Richard didn’t stop there: he and his partner are now constructing prosthetic hands for South African children who were born without fingers, such as this five-year-old boy, who was born with amniotic band syndrome, a condition that caused him to be born fingerless.

The incredible thing is that Richard’s work is just the beginning. Back in 2009, Eric Moger underwent surgery to remove a tumor from his face, leaving a gap the size of a tennis ball in his left cheek. Doctors used 3D printing to create a prosthetic that perfectly mirrors the right side of Eric’s face. This prosthetic is flexible like real skin and looks remarkably lifelike. And earlier this year, a man in the U.S. received a prosthetic implant that covered nearly a quarter of his skull’s surface.

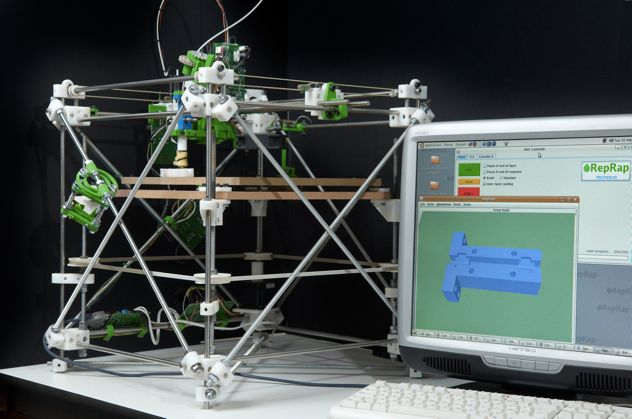

3. 3D Printers

Usually, someone has already created a 3D printer capable of printing more 3D printers. This printer, called RepRap, uses open-source designs, and nearly all of its parts can be printed by another printer (with the exception of some metal nuts and bolts). In 2008, the machine was put to the test at the University of Bath in the U.K., where it successfully printed a 'child' copy of itself. Just over three minutes later, the new 'child' had completed printing the first part for the next generation of the robo-lineage.

Since all the printer’s plans are publicly available online, a thriving community has grown around it, continually improving the design to increase efficiency. For instance, one person might download the blueprints, adjust them, and then upload the revised plans. This could be considered the first true example of hardware crowd-sourcing in history, and its future potential is limitless.

2. Robots

We seem to have an almost instinctual obsession with the idea of breathing life into something artificial. Maybe it's because robots are simply amazing.

In fact, there are several research teams already creating robots using 3D printing. For example, in Germany, Fraunhofer-Gesellschaft has designed an eight-legged spider robot, so easily printed that one researcher likened it to a “disposable rubber glove”—meaning that after its first use, it’s simpler to just print another one.

A collaboration between MIT and Harvard has also created a 3D printed robot that can, astonishingly, assemble itself. This robot uses “shape memory polymers” that allow it to fold itself into the correct shape once it has been printed.

Finally, there’s this robot, a voice-activated android that responds to commands in a suitably eerie manner. The plans for building it are available online for free, meaning anyone can join in and contribute to the creation of a robot army.

1. Body Parts

We’re not going to regenerate lost limbs like a lizard anytime soon, but we’re making significant progress. For instance, engineers at Cornell University printed a functional ear using cells taken from a patient’s rib. These cells were combined with a gel material that the 3D printer used to create a model—and after three months, the ear started producing its own cartilage.

It gets even better. A few months ago, we mentioned 3D printers in a list and speculated that one day we could print human organs. Well, that moment arrived just a month after the list was published. Organovo, a San Diego research firm, announced in April that they had successfully printed human liver tissue that could perform all the necessary liver functions. While they don’t have a full liver yet, the future is looking bright. This is the first step towards printing replacement organs on demand—potentially saving thousands of lives annually.