Human influence on the planet is becoming increasingly evident. Our energy demand is soaring, and the situation is only escalating. With a growing population, essential resources like space, water, and food are being heavily strained. Additionally, the environment is rapidly changing, resulting in extreme weather events that are drastically impacting cities globally.

To tackle some of these challenges, groundbreaking modifications are being applied to traditional construction techniques, aiming to make the future not only beautiful and clean but, above all, livable.

10. Bamboo Cities

While bamboo is often seen as a decorative plant in the West, it actually serves as a remarkable construction material. Growing rapidly, stronger than steel, and more resilient than cement, bamboo has the potential to revolutionize building practices. This is why Penda, an architectural firm in Beijing, China, is exploring its use as the primary resource for constructing entire cities.

The city would be eco-friendly, sustainable, and affordable. Buildings would be created by assembling bamboo rods into X-joints, then binding them with rope. Penda envisions constructing a city capable of accommodating 200,000 residents by 2023 using this method.

Once a building is finished, new components can be added both horizontally and vertically with ease. Additionally, a room or even an entire structure can be taken apart effortlessly, and since the materials consist solely of bamboo rods and rope, they can be reused.

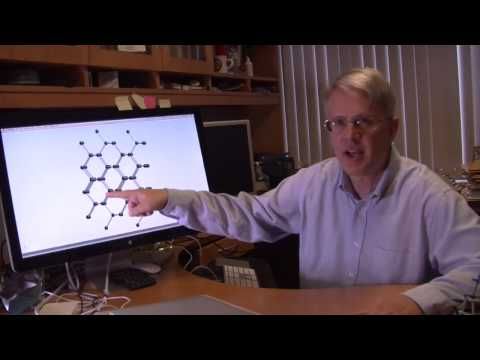

9. Diamond Nanothreads

Diamonds are, as far as we know, the hardest naturally occurring minerals on Earth. When structured correctly, their unparalleled strength makes diamonds a perfect candidate for construction material.

Researchers at Penn State University have developed revolutionary diamond nanothreads that are 20,000 times thinner than a human hair. Despite their microscopic size, diamond nanothreads are considered the strongest material on Earth—and possibly in the entire universe. In addition to being thin and powerful, they are astonishingly lightweight.

The researchers succeeded in creating these strands of ultrathin diamonds by applying alternating cycles of pressure to isolated benzene molecules in a liquid state. This process formed carbon atom rings that joined together in a precise chain.

While these nanothreads may not find use in conventional construction, they hold promise for ambitious projects, such as the cable for a space elevator, which could make space tourism more affordable.

8. Aerogel Insulation

Aerogel is not a recent discovery. In fact, it was first researched in the 1920s, with its findings published in 1932. The material is created by removing the liquid from gel and replacing it with gas, making it ultralight because it’s 90 percent air. When made into a blanket, aerogel serves as excellent insulation. It has been used for insulating piping in industrial sectors and even on the Mars rover.

Aspen Aerogels is one company aiming to use aerogel for home insulation. Their product, Spaceloft blankets, is easy to handle due to its lightness and thinness. Despite its minimal weight, the blankets provide two to four times the insulation per inch compared to traditional fiberglass or foam insulation.

Spaceloft blankets also allow water vapor to pass through them, and perhaps most impressively, they are fire-resistant. While homes wrapped in aerogel blankets may not be as fireproof as those in Fahrenheit 451, this type of insulation could certainly reduce the occurrence of residential fires.

The main issue is that aerogel is significantly more expensive than traditional insulation, although it can save money on energy bills in the long term. Additionally, not all homes are easily adaptable to this material. The blankets work best in older homes or new constructions specifically designed to incorporate aerogel insulation.

7. Road Printer

Paving a road traditionally takes a considerable amount of time. On average, a worker can pave just 100 square meters (1,100 ft) per day using conventional methods. Road printers, such as the Tiger Stone paving machine, aim to speed up this process by “printing” 300 square meters (3,200 ft) of cobblestone road in a single day.

Another example is RPS’s RoadPrinter, which can lay down 500 square meters (5,300 ft) of road per day. One to three operators feed loose bricks into the machine, which arranges them into a pattern similar to a carpet. Gravity then takes over as the machine places the bricks, followed by a steamroller to secure them in place.

The printers are powered by electricity and have few moving parts, making them simple to operate and maintain. Additionally, they are relatively quiet, especially when compared to traditional road-paving methods.

The main distinction between conventional roads and those created by these machines is that the printers use bricks instead of asphalt. However, brick roads offer several advantages over asphalt: they allow water filtration, expand when frozen, and have a longer lifespan.

6. Cableless Multidirectional Elevators

A significant challenge with large infrastructures is efficient movement within them. Humans can only walk so fast or so far, and each elevator shaft typically contains only one car. If you've ever used an elevator in a tall building, you know how long it can sometimes take to get a car.

German elevator company ThyssenKrupp is addressing these issues. Rather than relying on cables, their innovative design uses magnetic levitation technology, allowing the cars to move both vertically and horizontally. This would enable multiple cars to be used per shaft, reducing wait times and eliminating the need for numerous elevator doors.

Ultimately, the magnetic elevators would consume far less energy, making them a more eco-friendly option. ThyssenKrupp plans to begin testing this revolutionary elevator system in 2016 at a building on their research campus.

5. Solar Paint

A major criticism of solar panels is that they are large, unsightly, and not efficient enough. To address this, some researchers are developing solar cells that are so tiny and flexible they can be painted directly onto surfaces. For instance, a team from the University of Alberta has created a spray-on solar cell using nanoparticles of zinc and phosphorus.

If every homeowner were to coat their roof with this kind of solar paint, it could generate enough energy to power the entire house and reduce our dependence on fossil fuels. No retrofitting would be necessary, minimizing construction work. Additionally, solar paint is far cheaper to produce than traditional solar panels. Although the solar cells in the paint aren't efficient yet, researchers are working on improving this.

4. Vertical Cities

The United Nations predicts that by 2050, the global population will exceed 9.6 billion people, an increase of 2.3 billion compared to today. Furthermore, it's expected that 75% of the world's population will reside in cities, which will only worsen the space shortage in urban areas.

A potential solution to this issue is the creation of vertical cities. There are already plans to construct vertical cities in places like the Sahara Desert, the United Arab Emirates (UAE), and China.

These vertical cities would be enormous structures, providing housing, office spaces, and shopping centers. For example, Luca Curci Architects, an Italian firm, is designing a 189-story building in the UAE that will accommodate 25,000 people along with shops and businesses. This design could solve the space crisis and significantly lower the residents' carbon footprints since they wouldn’t need to leave the building.

These megastructures would be self-sustaining and environmentally friendly. Given their vast size, solar panels could be installed on the buildings. They would also incorporate geothermal energy and feature systems for collecting rainwater.

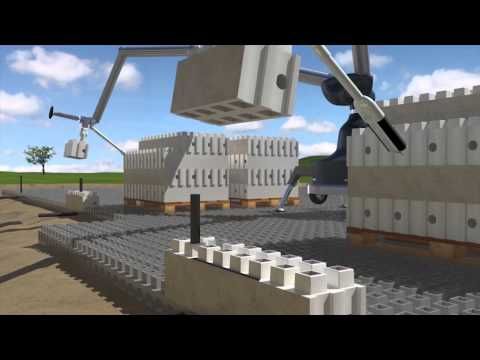

3. Robot Swarm Construction

In an effort to find new approaches to construction, researchers at Harvard looked to nature for ideas, specifically termites. Despite lacking central coordination, termites can construct large and intricate structures. Their method involves bringing dirt to an initial construction site, and if that location is occupied, they simply move on to the next available spot.

The TERMES Project adopts the concept of swarm construction, but with small robots instead of termites. These basic, cost-effective drones follow an initial blueprint, placing blocks in the available spaces until the structure is complete. This allows the swarm to operate with minimal human involvement once the design is established.

These robotic swarms are particularly useful for building in hazardous environments like space or underwater. They can also handle repetitive tasks that would be time-consuming for humans, performing construction more quickly and effectively thanks to their autonomous guidance system.

2. Smart Bricks

The Smart Bricks created by Kite Bricks are clearly influenced by Lego. These building blocks feature knobs on top, allowing them to connect just like Lego pieces. Smart Bricks are secured using rebar, and the design incorporates pieces of varying shapes stacked together.

Rather than using cement, these bricks are bonded with a robust, double-sided adhesive. Inside the structure, panels featuring customizable patterns can be affixed to the bricks, eliminating the need for drywall and paint. Additionally, components are available to construct floors and ceilings. The hollow centers of the bricks create space for insulation, plumbing pipes, and electrical wiring.

These bricks provide improved thermal energy management, greater flexibility in construction, and reduce building costs by around 50%.

1. Smart Concrete

Flooding worsens when there is insufficient drainage space, especially in urban areas where less soil is available to absorb water. To tackle this issue, the UK-based company Tarmac has developed a permeable asphalt solution called Topmix Permeable.

While standard concrete allows limited water penetration—about 300 millimeters (1 ft) per hour—Topmix Permeable enables 36,000 millimeters (118 ft) of water to pass through per hour, or approximately 3,300 liters (880 gallons) per minute.

Instead of traditional concrete, which uses sand, Topmix utilizes crushed granite pieces that are tightly packed together. Water can filter through the granite and either seep into the soil, be directed to a drainage system, or be collected in storage tanks. Not only does this help prevent flooding, but it also helps to keep streets drier, enhancing safety. Additionally, the water collected can be stored for future use in a variety of applications.

A limitation of permeable concrete is that it can only be used in climates where temperatures do not drop too low. Freezing temperatures could cause the material to expand, ultimately causing damage. Furthermore, the initial installation is more costly than traditional concrete, though cities might experience long-term savings if the material successfully alleviates flooding issues.