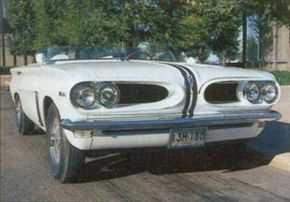

Initially, there was speculation that Pontiac's compact car would be a derivative of the rear-engine, air-cooled Chevy Corvair. A prototype from April 6, 1959, bore the name Ventura, with Polaris also under consideration. Explore more vintage car images.

©2007 Publications International Ltd.

Initially, there was speculation that Pontiac's compact car would be a derivative of the rear-engine, air-cooled Chevy Corvair. A prototype from April 6, 1959, bore the name Ventura, with Polaris also under consideration. Explore more vintage car images.

©2007 Publications International Ltd.Positioned between the conventional Ford Falcon and the unconventional Chevrolet Corvair, Pontiac carved out its unique niche with the 1961-1963 Pontiac Tempest.

Inspired by the Volkswagen's success in America and the 1958 economic downturn, the Big Three automakers shifted focus from "longer, lower, wider" to crafting compact cars for a growing market. While Ford's 1960 Falcon dominated sales, Chrysler's Valiant gained popularity for its European-inspired design and robust Slant Six engine. Even Studebaker and AMC had entered the compact car arena ahead of the Big Three.

Classic Cars Image Gallery

General Motors presented a wide range of compact cars, from the innovative rear-engine 1960 Corvair to the traditional Chevy II launched two years later. Positioned between these two Chevrolets in both timing and technology were the "B-O-P" compacts: the Buick Special, Oldsmobile F-85, and Pontiac Tempest.

These sibling models shared a 112-inch-wheelbase platform with unitized construction and a common Fisher body. However, their mechanical designs varied significantly. The Tempest stood out with its groundbreaking drivetrain, one of the most advanced systems in American automobiles at the time.

The Tempest's creation story is one of bold defiance and innovative cost-saving measures. A key driving force was Pontiac's determination to avoid a rebadged version of the Corvair.

GM aimed to expand the platform's use across divisions to boost sales and recoup development costs for the unique rear-engine compact. Pontiac, positioned just above Chevrolet in GM's hierarchy, was the natural choice, though Oldsmobile and Buick were also considered for their own variants.

Semon E. "Bunkie" Knudsen, Pontiac's general manager at the time, opposed the idea of a rebranded Corvair (proposed as the Polaris) for Pontiac. In a 1994 interview with Thomas A. DeMauro of High Performance Pontiac magazine, Knudsen explained his reasoning: "First, if a dealer claims this is a cutting-edge design, how can they justify the traditional drivetrains in Pontiac's other models? Second, the Corvair's rear-engine, air-cooled design limits differentiation. Without a grille to restyle or the option to swap in a Pontiac engine, how can I justify the $500 to $1,000 price increase for a Pontiac badge?"

While Pontiac was clear about what they didn’t want, they still had to decide on a direction for their compact car. On the next page, discover how John Z. DeLorean played a pivotal role in shaping the Pontiac Tempest.

For additional details about automobiles, check out:

- Classic Cars

- Muscle Cars

- Sports Cars

- New Car Search

- Used Car Search

DeLorean and the Pontiac Tempest

By September 1959, full-scale clay models were well underway for a Pontiac variant of the front-engine Y-body car, which would be shared with Buick and Oldsmobile.

©2007 Publications International Ltd.

By September 1959, full-scale clay models were well underway for a Pontiac variant of the front-engine Y-body car, which would be shared with Buick and Oldsmobile.

©2007 Publications International Ltd.Despite the demand for a compact car, the future of the emerging Pontiac Tempest appeared uncertain. With no support for Corvair variants at Pontiac, Buick, or Oldsmobile, a new model became essential. Pontiac spearheaded the X-100 program, an interdivisional initiative, creating a larger and heavily redesigned version of the Corvair's Y-body platform.

The wheelbase was extended from 108 to 112 inches, and adjustments were made to accommodate a front-engine design, as Buick and Pontiac were crafting engines for it. While the basic body structure was shared, each division added unique styling, ensuring none resembled the Corvair.

John Z. DeLorean, Pontiac's director of advanced engineering, was eager to leave his mark on the "Wide Track" segment of the project. To keep costs competitive, the compact Pontiac had to maximize the use of existing technology and production facilities. DeLorean and his team showcased their ingenuity by innovating within strict constraints.

DeLorean envisioned a car that transcended the compact category. Beyond affordability and efficiency, the new design aimed to deliver a smooth, big-car ride and comfortably seat six adults. The smaller size also hinted at sportiness, and DeLorean believed he could achieve these goals, along with a perfect 50/50 weight distribution, using a flat floor, a rear-mounted transaxle, and a flexible driveshaft. In contrast, Buick and Oldsmobile opted for traditional drivetrain layouts in their compact models.

The design was groundbreaking, though often misunderstood by the public. It was nicknamed "rope drive," a misnomer for the driveshaft, which was actually a forged-steel torsion bar made of high nickel, chrome, and molybdenum. Manual transmission Tempests used a 0.75-inch-diameter shaft, while automatics had a 0.65-inch version. Since the shafts transmitted unamplified engine torque, they were under less stress and could be smaller than conventional driveshafts.

The driveshafts underwent surface grinding and magnafluxing to detect flaws, followed by shot-peening and straightening. The final step involved applying a rust-resistant coating. Clearly, significant resources were invested in developing and producing the flexible driveshaft. Its advantages for the Tempest will be discussed shortly.

Discover how the Pontiac Tempest transformed the compact car segment with its innovative four-cylinder engine on the next page.

For additional insights into automobiles, explore:

- Classic Cars

- Muscle Cars

- Sports Cars

- New Car Search

- Used Car Search

The Pontiac Tempest and the Four-Cylinder Engine

The 1961 Pontiac Tempest stood out with its groundbreaking four-cylinder engine, setting it apart from competitors.

©2007 Publications International Ltd.

The 1961 Pontiac Tempest stood out with its groundbreaking four-cylinder engine, setting it apart from competitors.

©2007 Publications International Ltd.John Z. DeLorean's vision for the Pontiac Tempest included a unique four-cylinder engine. While Buick and Oldsmobile's Y-body models featured new V-6 or aluminum V-8 engines, DeLorean opted for an inline four-cylinder for Pontiac. This engine needed to outperform rival six-cylinder engines while being cost-effective to develop and produce.

Pontiac faced significant budget constraints, with most funds allocated to the innovative driveshaft system. The remaining drivetrain components had to rely on existing parts. DeLorean and his team concluded that a four-cylinder engine derived from the Pontiac V-8 was the most practical solution.

To validate the concept, engineers modified a production 389-cid Pontiac V-8 by disabling the left bank of cylinders and reinstalling it in a full-sized Pontiac. Despite the added drag from the deactivated cylinders, the modified engine achieved a top speed of 92 mph in the 4,000-plus-pound sedan while maintaining decent fuel efficiency.

Subsequently, the left bank of several 389 engines was removed, and specialized components were developed for production. These included a unique crankshaft, camshaft, two intake manifolds, a four-cylinder ignition system, and smaller accessories. The final 195-cid overhead-valve "slant-four" block retained much of the V-8's crankcase, making it heavy but robust.

A major advantage was the high level of interchangeability with the 389 engine. Both engines shared components like pistons, rings, connecting rods, bearings, cylinder heads, oil pans, pumps, and harmonic balancers. The four-cylinder engine also utilized the same machine tools and assembly line as the V-8, significantly cutting production costs.

For the 1961 model year, the "Trophy 4" engine came in three primary versions. The base model featured an 8.6:1 compression ratio and a one-barrel carburetor, producing 110 bhp at 3,800 rpm and 190 pound-feet of torque at 2,000 rpm. Automatic-transmission models, equipped with a more aggressive camshaft, delivered 130 bhp at 4,400 rpm and 195 pound-feet of torque at 2,200 rpm.

The second variant maintained the single-barrel carburetor but increased compression to 10.25:1, requiring premium fuel. Manual transmission models produced 120 bhp at 3,800 rpm and 202 pound-feet of torque at 2,000 rpm, while automatics generated 140 bhp at 4,400 rpm and 207 pound-feet at 2,200 rpm.

The most performance-oriented version featured a Rochester four-barrel carburetor and an even more aggressive camshaft. Both manual and automatic models delivered 155 bhp at 4,800 rpm and 215 pound-feet of torque at 2,800 rpm. Buick's 215-cid V-8, with a two-barrel carburetor, matched the horsepower but produced slightly more torque at 400 rpm lower than the top-tier four-cylinder.

While the Tempest offered ample power, Pontiac engineers also focused on handling. On the next page, discover what made the Pontiac Tempest such a smooth and enjoyable ride.

For additional details about automobiles, explore:

- Classic Cars

- Muscle Cars

- Sports Cars

- New Car Search

- Used Car Search

The Pontiac Tempest's Smooth Ride

To balance the engine's weight, Pontiac engineers reinforced the Tempest to ensure a driver-friendly experience.

©2007 Publications International Ltd.

To balance the engine's weight, Pontiac engineers reinforced the Tempest to ensure a driver-friendly experience.

©2007 Publications International Ltd.Despite the engine's successful placement, the Pontiac Tempest encountered further hurdles. While the slant-four engine achieved competitive power, low development costs, and shared many components with the 389 V-8, it had its downsides, including a hefty 557-pound weight and inherent vertical vibrations.

In a phone interview, retired Pontiac engineer Malcolm R. "Mac" McKellar, who played a key role in developing the slant-four, recalled significant vibration issues. "At 195 cubic inches, the engine was too large for a four-cylinder design without a balance shaft...We often called it a 'traveling fatigue machine.'"

Nearly all accessory mounts on the engine required reinforcement to handle the constant shaking. Despite this, contemporary road tests praised the car's smooth ride, often noting that it was hard to tell the engine was a four-cylinder while driving.

The solution lay in a combination of a curved driveshaft, torque tube, and specialized motor mounts. The curved driveshaft served dual purposes: it allowed for a nearly flat floor and eliminated the need for balancing like a traditional rigid shaft. The curvature, along with rubber bushings inside the torque tube, helped dampen vibrations. Additionally, soft rubber "doughnut" motor mounts at the front absorbed much of the engine's shaking, while the rear was stabilized by the transaxle mounts and torque tube.

"The four-cylinder Tempest offered a smooth ride, but if a spark plug fouled—common with leaded fuel—the mounts couldn't handle the extra vibration," McKellar explained. "While a V-8 might mask it, the slant-four would vibrate noticeably."

Behind the engine was a bellhousing connected to the torque tube. Manual transmission cars had a conventionally placed clutch. Both transaxles and the coil-spring, swing-axle rear suspension were adapted from the Corvair and modified to fit the torque tube. A three-speed manual was standard, with an optional two-speed automatic, dubbed "TempesTorque," based on the Powerglide system.

The engine's front was angled upward to align with the driveshaft and rested on a robust box-section subframe, which also supported the front suspension. The suspension featured an independent design with coil springs, unequal-length upper and lower control arms, ball joints, and a recirculating-ball steering system.

The drivetrain and suspension were designed as a self-contained unit. This modular approach enabled the Tempest to be assembled on the same production lines as full-sized Pontiac models, which used a "body-drop" method to attach the Fisher body to the completed perimeter-frame chassis.

Pontiac engineers devoted equal attention to the Tempest's aesthetics as they did to its engineering. On the next page, explore the design and styling of the Pontiac Tempest.

For additional insights into automobiles, explore:

- Classic Cars

- Muscle Cars

- Sports Cars

- New Car Search

- Used Car Search

1961 Pontiac Tempest Design

The 1961 Pontiac Tempest Custom stood out with its wrapped rear roof quarters, giving it the appearance of a convertible.

©2007 Publications International, Ltd.

The 1961 Pontiac Tempest Custom stood out with its wrapped rear roof quarters, giving it the appearance of a convertible.

©2007 Publications International, Ltd.The 1961 Pontiac Tempest was a triumph in both engineering and design. Designed by Jack Humbert, the Tempest featured a unique split grille and a bold Pontiac hood emblem. The front end, reminiscent of the 1959 Pontiac, showcased quad headlights and a sleek horizontal-bar grille.

Similar to its Y-body counterparts, the Tempest included a full-length bodyside wind-split at the beltline and a pronounced contour line running from the front fenders through the doors to the rear quarters. (The doors were shared across all three models.) On the Tempest, this line formed a body cove around the rear wheel wells. The beltline wind-split created a subtle fin above the rear quarter, ending near the small oval taillights. Both front and rear bumpers were simple blade designs.

The Tempest's dimensions placed it at the higher end of the compact car category, earning it the title of a "senior compact." Along with its 112-inch wheelbase, it measured 189.3 inches in length, 72.2 inches in width, and 56.8 inches in height (57.1 inches for wagons). The front and rear tread width was 56.8 inches.

The Tempest's interior was both stylish and spacious, featuring large windows that created a bright, open atmosphere with excellent all-around visibility. While the basic dashboard design was shared with Buick and Oldsmobile models, the Tempest had unique details, including a horizontal strip speedometer. The dashboard included standard warning lights, and automatic transmission models had the gear selector positioned on the dash to the driver's right.

Models with manual transmissions came equipped with a floor-mounted shifter. Both front and rear bench seats provided seating for six passengers. The nearly flat floor offered ample legroom, though a slight hump near the front accommodated the bellhousing.

Standard features included dual sun visors, turn signals, electric windshield wipers, and 6.00 × 15-inch blackwall tires, which helped manage the rear suspension's wide camber changes during travel.

Optional comfort and convenience features ranged from power steering to air conditioning, backup lights, and various interior and exterior decor packages. Notably, power brakes were not available, even as an option.

The Tempest debuted in four-door sedan and station wagon versions. Later in the model year, a coupe variant was introduced, along with the sporty, upscale LeMans model, which featured bucket seats.

The Pontiac Tempest became an instant success as soon as it arrived in showrooms. On the next page, discover the story behind the Tempest's triumph.

For additional insights into automobiles, explore:

- Classic Cars

- Muscle Cars

- Sports Cars

- New Car Search

- Used Car Search

The Success of the 1961 Pontiac Tempest

The Pontiac Tempest earned acclaim from both drivers and critics for its stylish design and exceptional handling.

©2007 Publications International, Ltd.

The Pontiac Tempest earned acclaim from both drivers and critics for its stylish design and exceptional handling.

©2007 Publications International, Ltd.The 1961 Pontiac Tempest made a strong impression upon its debut alongside the full-size 1961 Pontiacs on October 6, 1960. Critics lauded Pontiac for its innovative design and practical layout. Many appreciated the Tempest's smooth ride, compact size, and the performance of the slant-four engine. Interestingly, most reviewers favored the automatic transmission for its quieter operation and enhanced power from the more aggressive camshaft.

On the downside, the power steering was criticized for being overly slow and lacking feedback. Journalists also noted a sudden loss of rear-wheel grip at the limits of traction, a result of the softly tuned swing-axle suspension that caused the rear wheels to tilt into a positive-camber position, reducing tire contact with the road.

Despite these drawbacks, the positive reception outweighed the negatives. In fact, Motor Trend named the 1961 Tempest its "Car of the Year," marking Pontiac's second such award in three years. In the March 1961 issue, editor Don Werner wrote, "The Tempest represents a clear step forward in automotive design, meeting the criteria for the award perfectly." He added, "The Pontiac Tempest sets new benchmarks and serves as a blueprint for the American car of the 1960s."

Werner's remarks echoed the optimism of many enthusiasts who saw the Tempest as the start of a new era in American automotive history, emphasizing balance, efficiency, and a move away from unnecessary bulk.

The public also responded favorably, with 100,783 Tempests sold—a solid start, though trailing behind the Corvair, Falcon, and Valiant that year. (The Tempest outsold its GM Y-body siblings, however.) The slant-four engine proved far more popular than the 215-cid V-8, with only 2,004 units equipped with the V-8, including just three with a manual transmission.

For the 1962 model year, the Tempest underwent subtle yet evolutionary updates. A convertible was introduced, available in both Tempest and LeMans versions. The front end received a redesign, replacing the split grille with a tri-section layout featuring a Pontiac "arrow-point" emblem at its center. The hood was also updated with a "waterfall" design that seamlessly integrated into the grille's central element.

Engine improvements were also made. A redesigned intake manifold for the four-barrel slant-four engine boosted output by 11 bhp, reaching 166 at 4800 rpm, though torque figures stayed the same. The manual-transmission "87Z" engine was upgraded with four-bolt main bearings.

The 87Z engine served as the foundation for a special NASCAR-approved version available through Pontiac's parts network. It featured the four-bolt block, a cylinder head from the 389 Super Duty V-8, a four-cylinder version of the McKellar No. 8 mechanical-lifter camshaft, and an aluminum four-barrel intake manifold fitted with a large Carter AFB carburetor. Pontiac rated this engine at 184 bhp at 5600 rpm, though estimates suggested actual output was closer to 240 bhp at 6500 rpm, largely due to the intake manifold's ram effect.

The 215 V-8 also saw a power increase, gaining 30 horsepower over the previous year for a total of 185. However, the low-compression four-cylinder engine paired with the automatic transmission was downgraded to 115 bhp.

Following the success of the 1961 Pontiac Tempest, a new model was inevitable. On the next page, explore the 1962 Pontiac Tempest.

For additional insights into automobiles, explore:

- Classic Cars

- Muscle Cars

- Sports Cars

- New Car Search

- Used Car Search

1962 Pontiac Tempest

The rarest 1963 Pontiac Tempest was the base-model Safari wagon, with only 4,203 units produced. It featured a long-handled floor shifter for the three-speed transmission.

©2007 Publications International Ltd.

The rarest 1963 Pontiac Tempest was the base-model Safari wagon, with only 4,203 units produced. It featured a long-handled floor shifter for the three-speed transmission.

©2007 Publications International Ltd.The 1962 Pontiac Tempest adhered to the principle, "If it's not broken, don't fix it." The rear suspension, borrowed from the Corvair, was slightly modified to accommodate the torque tube and curved driveshaft.

Production numbers surged in 1962, with 143,193 Tempests and LeMans models built. This increase was likely due to the expanded lineup and the public's growing acceptance of the car's advanced technology.

The 1963 model year brought significant changes to Pontiac's senior compact. New sheet-metal below the beltline gave the Tempest a more refined appearance. The split-grille design returned, featuring an eggcrate mesh. The body became slightly more angular, with longer rear quarters adding five inches to its length. The rear end was also redesigned, with Tempests sporting two small, vertical round taillamps per side, while LeMans coupes and convertibles featured thin rectangular lenses with ribbed stainless trim.

Under the hood, the updates were equally noteworthy. The four-cylinder engine received a new cylinder head, and the 115-bhp version became the base engine regardless of transmission. The aluminum V-8 was discontinued, replaced by a small-bore version of the cast-iron 389, now displacing 326 cubic inches. The two-barrel carburetor version produced 260 bhp at 4800 rpm and 352 pound-feet of torque at 2800 rpm. Later, a high-output version with a Carter AFB four-barrel carburetor delivered 280 bhp at 4800 rpm and 355 pound-feet of torque at 3200 rpm. The four-speed manual transmission was not offered with the 326 due to insufficient torque capacity.

The automatic transaxle also saw updates, with distinct versions for the slant-four and V-8 engines. These differed mainly in torque-converter size and clutch pack count. A "Park" position was added, and LeMans models received an exclusive floor shifter.

The rear suspension was upgraded as well. The swing-axle design used in 1961 and 1962 was replaced with a trailing-arm setup similar to the 1963 Chevrolet Corvette. U-joints at both ends of the axles allowed the wheels to maintain consistent camber, improving handling and reducing the Tempest's tendency to oversteer.

Like all great things, the Pontiac Tempest's journey eventually came to an end. Discover how on the next page.

For additional insights into automobiles, explore:

- Classic Cars

- Muscle Cars

- Sports Cars

- New Car Search

- Used Car Search

The End of the Line for the Pontiac Tempest

The Pontiac Tempest was ultimately overshadowed by the LeMans.

©2007 Publications International Ltd.

The Pontiac Tempest was ultimately overshadowed by the LeMans.

©2007 Publications International Ltd.The Pontiac Tempest eventually succumbed to competition from the LeMans. While the LeMans shared many features with its more basic counterpart, it evolved into a more upscale model, positioning itself as a smaller version of the Grand Prix.

Reviewers praised the 1963 models for their build quality, interior design, instrumentation, and the new V-8's performance. However, they criticized issues like transaxle noise, sluggish steering, and insufficient braking, particularly with the V-8 engine.

Despite improvements across the board and a lack of technological advancements from competitors, the Tempest family saw declining sales. Production dropped to 69,832 Tempests and 61,658 LeMans models, totaling 131,490 units. Product planners anticipated this decline would continue as the compact car market became increasingly saturated.

High production costs and market realities signaled the end for the transaxle Tempests. While the cars faced issues like transaxle durability and timing chain problems with the slant-four engine, the innovative curved driveshaft rarely caused trouble. Critics argued that the transaxle Tempests were too experimental and unproven for mass production.

Ultimately, the 1961-63 Pontiac Tempests didn't spark a new trend in American automobiles. Instead, they became a fascinating footnote in automotive history, showcasing cutting-edge technology in the compact car segment. These models were among the most innovative of the 1960s, leveraging advanced engineering and efficient use of manufacturing resources. Ironically, their more conventional successor, the GTO, became a trendsetter, igniting the muscle car era. The rest, as they say, is history.

However, the Tempest's story doesn't end just yet. On the next page, discover the tale of the Tempest convertible that nearly came to be.

For additional insights into automobiles, explore:

- Classic Cars

- Muscle Cars

- Sports Cars

- New Car Search

- Used Car Search

The Pontiac Tempest Convertible

Pontiac transformed a Tempest convertible prototype into the supercharged, two-seat Monte Carlo show car, showcased in 1961 and, with minor updates, in 1962.

©2007 Publications International Ltd.

Pontiac transformed a Tempest convertible prototype into the supercharged, two-seat Monte Carlo show car, showcased in 1961 and, with minor updates, in 1962.

©2007 Publications International Ltd.In 1961, Pontiac aimed to transform the Tempest into a striking show car. Since the 1954 Bonneville Special captivated audiences at the General Motors Motorama, Pontiac had dreamed of producing its own two-seat sports car. However, Chevrolet's efforts to shield the Corvette from internal competition kept this dream from becoming reality.

Until the Fiero debuted in 1984, Pontiac had to quench its sports-car ambitions by creating one-off show cars. The 1961-62 Tempest Monte Carlo stood out as a particularly fascinating prototype, as its production-based design suggested it could have been mass-produced.

Using a prototype for the 1962 Tempest convertible (no 1961 convertibles were made), engineers removed a 15-inch section from the unit body between the door and rear wheels, then welded the remaining parts together. This created a two-seater with a 97-inch wheelbase and an overall length of 175 inches. Custom eggcrate grilles were fitted into the original openings, and the stock windshield was replaced with a Plexiglass windscreen that extended to the doors. A fiberglass tonneau with dual headrest fairings replaced the standard rear deck.

The interior was both stylish and practical. It featured twin production-style bucket seats with custom side bolsters and retractable seatbelts, upholstered in blue leather. A custom console housed the shifter and a manifold vacuum gauge, while a set of performance gauges were installed in the stock dashboard opening.

The Monte Carlo's engine was a heavily modified version of the 195-cid Pontiac four. It included a Mickey Thompson supercharger system, utilizing a GMC 3-71 blower and a Carter AFB four-barrel carburetor fitted with a special 90-degree elbow. True to show-car tradition, the engine was adorned with chrome and polished aluminum components. It was connected to a rear-mounted four-speed transaxle via the Tempest's distinctive curved driveshaft.

The Tempest Monte Carlo was painted in pearlescent white with dual blue racing stripes across the hood and rear deck. During the 1961 show season, it featured Halibrand knock-off racing wheels with Firestone Super Sport tires. When Pontiac showcased it again in 1962, the wheels were swapped for knock-off wire wheels fitted with Goodyear Blue Streak tires.

As part of its exhibition duties, the Tempest Monte Carlo was displayed alongside Chevy's Corvair Sebring Spyder show car at select racetracks. After its tour ended, Pontiac had no further plans for the car. Instead of being scrapped, as was typical for non-production vehicles, it was gifted to former GM vice president Ed Cole. Before delivery, it was returned to Pontiac Engineering, where the supercharged four-cylinder engine was replaced with a milder 215-cid aluminum V-8 at Cole's request.

The Plexiglass windscreen was replaced with a standard windshield, and a small convertible top was added. The Monte Carlo remained in this configuration with the Cole family until Ed Cole's untimely death in a 1977 plane crash. His widow later donated the car to the San Antonio Museum of Transportation, where it was stored for several years.

When the Texas Science Center Automotive Collection closed in 1994, its inventory was auctioned by Christie's. At the prestigious Pebble Beach sale, the Monte Carlo sold for nearly $60,000. According to Christie's, the current owner prefers to remain anonymous.

There's one more variation of the Pontiac Tempest to explore. On the next page, discover the story of the Lightweight Super Duties.

For additional insights into automobiles, explore:

- Classic Cars

- Muscle Cars

- Sports Cars

- New Car Search

- Used Car Search

The 1963 Pontiac Tempest Lightweight Super Duties

Although modified over time, one of the two prototype Super Duty coupes still survives.

©2007 Publications International Ltd.

Although modified over time, one of the two prototype Super Duty coupes still survives.

©2007 Publications International Ltd.Pontiac appeared committed to tailoring the Tempest for nearly every automotive purpose. The next iteration was the Pontiac Tempest Lightweight Super Duties, engineered to dominate America's drag strips.

By 1963, Super Stock drag racing had become a major motorsports trend, drawing the interest of competitors, fans, and manufacturers eager to prove who built the fastest cars. While Pontiac had started the decade strong with its Super Duty parts program and factory-built SD Catalina and Grand Prix race cars, rivals like Dodge and Plymouth were gaining ground. Their 426-cid wedge-head race engines and lightweight bodies were beginning to overshadow Pontiac's efforts.

Pontiac initially addressed the 200- to 300-pound weight disadvantage of the Super Dutys by introducing aluminum body panels. This weight-reduction strategy peaked with Catalinas featuring frames drilled with large holes. (Automotive journalist Roger Huntington famously called them "Swiss Cheese" frames, a nickname that stuck for obvious reasons.)

Unfortunately, these measures didn't yield the desired results. Frames sometimes broke due to excessive metal removal, and the cars remained too heavy after Chrysler introduced their own aluminum body parts. To counter the "Max Wedge" Mopars, Pontiac needed a bold move, leading to the Tempest being enlisted to uphold Pontiac's reputation on the drag strip.

The concept of fitting Pontiac's powerful 421-cid Super Duty race engine into the compact Tempest body had been in development since 1962. Racers like Mickey Thompson, Royal Pontiac dealership, and even Pontiac Engineering had experimented with their own versions. While independent efforts used traditional transmissions and rear ends from full-size models, Pontiac aimed to retain the rear-mounted transaxle to add weight over the drive wheels, compensating for the era's limited tire technology.

The main challenge was that stock transaxles couldn't handle the 421's power. Engineers developed a new four-speed transaxle called the "Powershift." Simplified, the Powershift combined two Corvair Powerglide two-speed automatic transaxles to create four forward speeds. The project involved integrating existing parts with over 200 new components and casting a custom housing to hold everything together.

While the Powershift wasn't entirely invincible, it proved to be significantly more robust than a standard production unit. This rear-mounted four-speed transmission offered the flexibility of using either a clutch or a torque converter, allowing racers to select the optimal setup for their specific competition needs. With a sole final-drive ratio of 3.90:1, only 14 units were manufactured—one for each car produced—and no additional cases were ever made.

Once the transaxle issue was resolved, focus shifted to the engine. A new low-profile dual-quad intake manifold was designed to fit under the Tempest hood, and the crankshaft was modified with six additional holes in the end flange to connect to the curved driveshaft. This iteration of the 421 Super Duty engine featured a 12:1 compression ratio and was officially rated at 405 bhp, though real-world performance suggested it was closer to 500 bhp.

In a bid to reduce weight, the compact Pontiacs were equipped with all-aluminum front ends, and the doors were stripped of much of their internal reinforcement. Production of these racing models included two prototype Tempest coupes, six LeMans coupes, and surprisingly, six Tempest station wagons. The rationale behind the wagons was to increase rear-wheel weight distribution, which was crucial given the traction challenges even the larger Catalinas faced. These lightweight compacts needed every advantage to effectively transfer their power to the ground.

Sadly, all the hard work went to waste. On January 24, 1963, General Motors, fearing potential antitrust action from the U.S. Department of Justice, announced its withdrawal from all factory-backed racing endeavors. The 'Win on Sunday, Sell on Monday' strategy had proven too successful, driving GM's market share perilously close to the 60% threshold that would prompt a federal inquiry.

Pontiac's Super Duty initiative was abruptly halted, and most teams swiftly moved to secure factory agreements with Chrysler and Ford. The handful of 1963 Super Duty cars that escaped GM before the shutdown ended up in the hands of private racers and collectors. Today, these vehicles are exceedingly rare and highly prized relics of the factory racing era. Only four coupes and one wagon are known to exist, with just one coupe and the featured wagon restored to their original specifications.

Initially named 'Instant' and piloted by Harold Ramsey, this vehicle is often called the 'Union Park wagon' due to its sponsorship by Union Park Pontiac. Currently, it belongs to Randy and Jean Williams from Columbia City, Indiana, and underwent restoration by Scott Tiemann of Supercar Specialties in Portland, Michigan. Staying true to its original factory setup, the wagon features the authentic 405-horsepower 421 Super Duty V-8 engine and the rear-mounted four-speed Powershift trans-axle. The restoration process was marked by exceptional craftsmanship, meticulous research, and nearly two decades of gathering rare parts.

After its restoration, the Union Park wagon made its first public appearance at the 1999 Ames Performance Pontiac Nationals in Norwalk, Ohio. During the event, renowned Pontiac racer Arnie 'The Farmer' Beswick drove the car to a smooth 12.4-second run at over 112 mph—on its original tires—with Randy Williams riding alongside. Beswick believed the car had the potential to achieve 11.5 seconds. Today, the Union Park wagon is showcased in the Williams' Pontiac museum in Columbia City, alongside other original Super Duty race cars.

For additional details about automobiles, explore the following:

- Classic Cars

- Muscle Cars

- Sports Cars

- New Car Search

- Used Car Search