Photo Collection: Concept Vehicles Among the most iconic Chrysler Turbine concept cars was the bronze coupe. Chrysler distributed 50 of these vehicles to 203 individuals from 1963 to 1966 for real-world testing. Explore more images of concept cars.

©2007 Publications International, Ltd.

Photo Collection: Concept Vehicles Among the most iconic Chrysler Turbine concept cars was the bronze coupe. Chrysler distributed 50 of these vehicles to 203 individuals from 1963 to 1966 for real-world testing. Explore more images of concept cars.

©2007 Publications International, Ltd.The Chrysler Turbine Car, a bronze hardtop reminiscent of a Thunderbird with a distinctive whine, remains unforgettable. However, this striking vehicle was just one outcome of an extensive initiative that generated numerous innovative Chrysler Turbine concept cars during the 1950s and 1960s.

The initiative appeared to herald the imminent arrival of turbine-powered vehicles in everyday life—a reality briefly experienced by the hundreds of individuals who test-drove the 50 Turbine Cars during a three-year consumer trial. Despite Chrysler's advancements in refining a functional turbine automobile, external factors ultimately relegated the futuristic engine to obscurity, leaving its potential unfulfilled.

The gas turbine shares a connection with the jet engine, which was patented by England's Frank White in 1930. Rolls-Royce accelerated the progress of jet-powered fighter aircraft, which arrived too late to significantly impact World War II but played a crucial role in the Korean War.

During the interwar period, America's leading automakers initiated development of aircraft turbines (Chrysler produced a turbo-prop for the U.S. Navy Bureau of Aeronautics in 1948). However, they only began exploring automotive applications in the mid-1950s, possibly influenced by Rover's experimental turbine car in Britain in 1952. Among Detroit manufacturers, Chrysler stood out for its dedication to turbine-powered cars, while Ford and GM focused primarily on turbine applications for trucks.

Similar to a jet engine, the turbine's core component is a wheel adorned with blades or vanes. A mixture of fuel and air passes over these vanes, causing the wheel to spin and generate power. In many designs, including Chrysler's, this "power turbine" also drove a "first-stage turbine" connected to a compressor. The compressor pressurized the mixture for ignition, which was triggered by an igniter resembling a spark plug.

This straightforward design greatly appealed to Chrysler and others, as it involved fewer components, suggesting reduced maintenance needs. For drivers, the turbine offered unparalleled smoothness compared to traditional engines, as it generated rotary motion directly.

The 1954 Plymouth represented one of Chrysler's early turbine concept cars. This image highlights the turbine's ability to remain cool externally despite its intense internal temperatures.

©2007 Publications International, Ltd.

The 1954 Plymouth represented one of Chrysler's early turbine concept cars. This image highlights the turbine's ability to remain cool externally despite its intense internal temperatures.

©2007 Publications International, Ltd.Additional benefits included rapid warm-up times (providing immediate cabin heating in winter), reliable starts in cold weather, compatibility with diverse fuels (Chrysler boasted the turbine could run on everything from peanut oil to Chanel No. 5), minimal oil usage, and no requirement for antifreeze.

Balancing these advantages were four significant drawbacks: extreme internal temperatures (exceeding 2,000 degrees Fahrenheit); performance characteristics more suited to constant speeds, ideal for aircraft but not typical for cars; a lack of natural "engine braking," crucial for road use; and elevated emissions of nitrogen oxides (NOx). Despite these challenges, Chrysler managed to address or significantly mitigate each issue over approximately 25 years of research and development.

Excessive heat posed the most significant challenge. To tackle this, Chrysler engineers, led by George Huebner, Jr., often referred to as Highland Park's "Mr. Turbine," created a device called a "regenerator." This rotating heat exchanger effectively reduced exhaust-gas heat, lowering internal temperatures and improving fuel efficiency beyond standard expectations.

Early efforts also focused on enhancing operational adaptability and creating materials capable of withstanding extreme temperatures.

Discover the evolution of Chrysler's turbine engines on the following page.

For additional insights into concept cars and the production models they inspired, explore:

- Concept Cars

- Classic Cars

- Consumer Guide auto show reports

- Future Cars

CR Gas Turbine Engines

The 1954 Plymouth Belvedere hardtop served as the experimental platform for Chrysler's CR1 gas turbine engine. Project engineer George Huebner Jr. is pictured on the right.

©2007 Publications International, Ltd.

The 1954 Plymouth Belvedere hardtop served as the experimental platform for Chrysler's CR1 gas turbine engine. Project engineer George Huebner Jr. is pictured on the right.

©2007 Publications International, Ltd.By 1954, Chrysler's first CR gas turbine engine for automobiles, named "CR1" and producing 100 horsepower, was completed. It was fitted into a standard-looking 1954 Plymouth Belvedere hardtop, which successfully debuted at the inauguration of Chrysler's new Chelsea, Michigan, testing facility. A comparable engine was later installed in a 1955 Belvedere four-door model.

Rapid advancements followed. A refined CR1 engine, featuring advanced metallurgy, powered a 1956 Belvedere "Turbine Special" sedan during a cross-country journey that year. While it performed admirably, its fuel efficiency of 13 miles per gallon was considered poor even by the standards of the time.

Following this, a more advanced CR2 engine was introduced, delivering approximately 200 horsepower. This improvement was achieved through the use of cost-effective yet durable alloys that enhanced resistance to heat and oxidation.

The 1956 Plymouth Turbine Special, equipped with a CR1 engine, achieved only 13 miles per gallon during a cross-country trip.

©2007 Publications International, Ltd.

The 1956 Plymouth Turbine Special, equipped with a CR1 engine, achieved only 13 miles per gallon during a cross-country trip.

©2007 Publications International, Ltd.This engine was installed in a second 1956 Plymouth sedan and a 1957-58 model before being showcased in a 1959 Fury-based Turbine Special hardtop sedan. During a 1,200-mile demonstration drive from Detroit to Princeton, New Jersey, this car achieved a more respectable 18 miles per gallon.

By 1960, the third-generation CR2A was developed. Its key innovations included a swiveling fuel nozzle system and first-stage turbine vanes adjustable to three different angles based on throttle input.

These advancements introduced a degree of engine braking (addressing a major limitation of turbine engines) and improved acceleration. They also significantly minimized the frustrating "throttle lag" present in earlier models. While the CR1 required seven seconds to reach full power from idle, the CR2A achieved the same in just 1.5 to 2 seconds.

Observe the four central exhaust ports on this 1958 Plymouth, which houses the CR2 turbine engine.

©2007 Publications International, Ltd.

Observe the four central exhaust ports on this 1958 Plymouth, which houses the CR2 turbine engine.

©2007 Publications International, Ltd.The CR2A engines were first fitted into three distinct 1960 vehicles: a nearly standard Plymouth Fury hardtop, a 2.5-ton Dodge truck, and the strikingly designed TurboFlite, which debuted in 1961.

The TurboFlite was crafted by Maury Baldwin, who later described it as the ultimate "Virgil Exner" show car: "We integrated numerous innovative features. The entire cockpit above the beltline lifted to allow entry. A deceleration flap, similar to those on race cars, was mounted between the fins. The headlights were retractable. Ghia constructed the car based on a 1/8-scale model and full-size drawings. It was arguably one of the most meticulously engineered show cars we ever created."

To learn how these models paved the way for the Turbine Car, continue reading on the following page.

For additional insights into concept cars and the production vehicles they inspired, explore:

- Concept Cars

- Classic Cars

- Consumer Guide auto show reports

- Future Cars

Chrysler Turbine Car

One of the two 1962 Dodge Darts equipped with a turbine engine demonstrated significant fuel efficiency improvements compared to Chrysler's earlier gas turbine experiments from the 1950s.

©2007 Publications International, Ltd.

One of the two 1962 Dodge Darts equipped with a turbine engine demonstrated significant fuel efficiency improvements compared to Chrysler's earlier gas turbine experiments from the 1950s.

©2007 Publications International, Ltd.The development of the 1960s Chrysler Turbine Car began in the 1950s, during which Chrysler engineered three iterations of turbine engines.

The third engine, the CR2A, was installed in four 1962 hardtop coupes—two Dodge Darts and two Plymouth Furys—which preceded the Turbine Car. One of the Turbo Darts, as they were known, completed a durability run from New York to Los Angeles, achieving better fuel efficiency than the accompanying piston-powered "control" car and outperforming the 1956 Turbine Special in both time and efficiency.

The 1962 turbine engines were showcased at numerous Dodge and Chrysler-Plymouth dealerships and even traveled to Europe for demonstrations at Montlhéry in France and Silverstone in England. Encouraged by the overwhelmingly positive feedback, Chrysler decided to produce 50 turbine-powered cars for consumer testing.

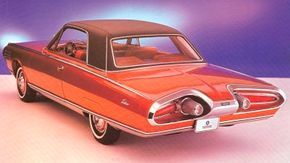

This initiative led to the iconic bronze hardtop, introduced in May 1963. Designed specifically for the consumer program by Elwood Engel, who had taken over as head of Chrysler Styling two years earlier, the car became a symbol of innovation.

Engel, who had previously worked on the 1961-63 Thunderbird at Ford, brought his design expertise to the project. The influence of the Thunderbird was so apparent that the Turbine Car earned the nickname "Engelbird" among enthusiasts.

Despite the similarities, the Turbine Car had distinct features beyond its engine. With a 110-inch wheelbase, it was three inches shorter than the Thunderbird, and its styling was unique at both ends. The front design was simple yet somewhat blunt, while the rear featured dramatic "boomerang" recesses housing large, angled taillights and backup lamps in turbine-inspired housings.

The headlight bezels and wheel covers also incorporated a rotary-blade theme. Every vehicle in the consumer program featured a black vinyl roof to complement the distinctive "Turbine bronze" exterior.

Test driver George Stecher is pictured with one of the iconic bronze 1963 Turbine Cars and the series of turbine engines Chrysler had developed up to that point.

©2007 Publications International, Ltd.

Test driver George Stecher is pictured with one of the iconic bronze 1963 Turbine Cars and the series of turbine engines Chrysler had developed up to that point.

©2007 Publications International, Ltd.The interiors featured a bronze theme, accommodating four passengers on individual vinyl-upholstered seats, complemented by a cylindrical center console running the length of the cabin. Additional features included power steering, brakes, and windows, along with an adapted TorqueFlite automatic transmission, a radio, air conditioning, and specialized instruments such as a tachometer and a turbine-inlet temperature gauge.

Under the hood was Chrysler's advanced fourth-generation gas turbine, the A-831. Key advancements included continuously adjustable first-stage turbine vanes, controlled by throttle position, and dual regenerators rotating vertically on either side of a central burner.

The A-831 was more compact, lighter, and quieter than the CR2A, with improved responsiveness and throttle lag reduced to 1.0-1.5 seconds. Its maximum engine speed after gear reduction was 4680 rpm, compared to the CR2A's 5360 rpm. While horsepower decreased by 10 to 130, torque surged from 375 to an impressive 425 pounds-feet.

In all other aspects, the Turbine Car was quite conventional, though its TorqueFlite automatic lacked a torque converter (unnecessary for this design) and utilized Chrysler's signature "Unibody" construction.

Due to the limited production volume, the 50 "production" Turbine Cars and five prototypes (three of which featured unique roof and paint designs) were outsourced to Ghia in Italy, which could manufacture them more cost-effectively than Chrysler.

Continue to the next page to learn more about the performance of the Chrysler Turbine cars.

For additional insights into concept cars and the production models they inspired, explore:

- Concept Cars

- Classic Cars

- Consumer Guide auto show reports

- Future Cars

Turbine Car Evaluation Program

The 1963 Chrysler Turbine Car received widespread acclaim for its design. Each car featured a Turbine Bronze exterior and interior, paired with a black vinyl roof.

©2007 Publications International, Ltd.

The 1963 Chrysler Turbine Car received widespread acclaim for its design. Each car featured a Turbine Bronze exterior and interior, paired with a black vinyl roof.

©2007 Publications International, Ltd.Following the announcement of its Turbine Car evaluation program, Chrysler's Highland Park headquarters was inundated with over 30,000 inquiries. The program allowed each "consumer representative" to use a Turbine Car for approximately three months.

The test program included participants from all 48 contiguous states, ranging in age from 21 to 70. Between 1963 and early 1966, a total of 203 individuals drove the 50 Turbine Cars.

By the following year, Chrysler released a report indicating that the Turbine Cars required minimal to no maintenance compared to traditional piston-engine vehicles.

However, the company never disclosed fuel efficiency figures, which were presumably disappointing. One in four drivers criticized the car's poor fuel economy (likely due to a lack of alternative fuels like peanut oil), and one in three complained about throttle lag. Despite these issues, many praised the car's smooth, vibration-free operation and stylish design.

Although Chrysler never provided a Turbine Car to journalists for review, writer John Lawlor secured a test drive near the end of the consumer trial. He praised the car's smooth operation but noted frustrations with the limited engine braking and the throttle lag, which he confirmed to be 1.0-1.5 seconds as claimed.

Lawlor also found the fuel efficiency disappointing, averaging just 11.5 mpg, despite primarily using inexpensive kerosene. However, he commended the car's acceleration, which reached 60 mph in under 10 seconds—a remarkable feat for a vehicle weighing 4,100 pounds. This performance dispelled myths about turbines being sluggish.

While the Turbine Cars were being circulated among consumers, Chrysler was already advancing its technology, testing a fifth-generation engine (A-875) in a 1964 Plymouth. However, this model was quickly overshadowed by the arrival of a sixth-generation design in 1966.

This 1966 Dodge Coronet 500 hardtop served as a test vehicle for Chrysler's sixth-generation turbine engine.

©2007 Publications International, Ltd.

This 1966 Dodge Coronet 500 hardtop served as a test vehicle for Chrysler's sixth-generation turbine engine.

©2007 Publications International, Ltd.Installed in a Dodge Charger fastback and Coronet 500 hardtop, this engine featured enhanced engine braking and an innovative split accessory drive system. Components like the power steering pump were powered directly by the power turbine, while the compressor turbine handled engine-related systems such as the fuel pump.

Chrysler initially intended to produce 500 turbine-powered Coronets for public sale but abandoned the plan due to upcoming government emissions regulations. Despite this, the 1966 hardtop prototype remained in Chrysler Engineering until 1972, when the turbine project took an unexpected turn.

To discover what unfolded next, proceed to the following page.

For additional insights into concept cars and the production models they inspired, explore:

- Concept Cars

- Classic Cars

- Consumer Guide auto show reports

- Future Cars

Government Oversight of the Turbine Car

The seventh and final iteration of Chrysler's turbine engine was installed in two 1976 Dodge Aspen sedans.

©2007 Publications International, Ltd.

The seventh and final iteration of Chrysler's turbine engine was installed in two 1976 Dodge Aspen sedans.

©2007 Publications International, Ltd.NOx emissions continued to pose a significant challenge for Chrysler's Turbine Car initiative, particularly as government scrutiny intensified in the 1970s. However, in a surprising move, the newly established Environmental Protection Agency was convinced—partly by project engineer George Huebner's persuasive presentation—to award Chrysler $6.4 million to further turbine engine development.

The grant aimed to address NOx emissions, improve fuel efficiency, reduce production costs, and ensure performance and reliability comparable to "traditional piston-powered compact American cars" [emphasis added].

Following tests with three 1973 mid-size Dodge/Plymouth sedans, Chrysler introduced its seventh-generation turbine engine. While it returned to a single regenerator design, it featured advanced electronic fuel control for greater precision.

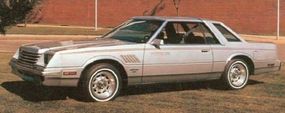

This engine was first used in two 1976 Dodge Aspens and later in a unique T-roof coupe, essentially a modified 1977 Chrysler LeBaron with sharp front fenders, concealed headlights, and a narrow vertical grille. Although horsepower dropped to 104 compared to the sixth-generation's 150, the new turbine operated at higher temperatures, enabling 125 horsepower with water injection at the compressor inlet and adjusted inlet guide vanes.

Subsequently, Chrysler secured a comparable agreement (alongside GM and Ford) from the Energy Research and Development Administration (ERDA), which later merged with other agencies to form the current Department of Energy (DOE).

Continuing their pursuit of turbine perfection, engineers nearly eliminated throttle lag, reduced hydrocarbon and carbon monoxide emissions to meet regulatory standards, and achieved fuel efficiency comparable to traditional piston engines. As per the contract, Chrysler deployed its two turbine-powered Aspens in Washington, D.C., where they operated without issues.

However, by 1979, achieving lower NOx levels still appeared unattainable. Compounding the issue, Chrysler was nearing bankruptcy, and a severe economic downturn led to widespread federal budget cuts.

This unassuming 1980 Dodge Mirada marked the final turbine-powered vehicle from Chrysler.

©2007 Publications International, Ltd.

This unassuming 1980 Dodge Mirada marked the final turbine-powered vehicle from Chrysler.

©2007 Publications International, Ltd.Consequently, the DOE ceased funding in early 1981, prompting Chrysler to completely halt turbine research after over 25 years and an investment exceeding $100 million of its own funds, plus $19 million in taxpayer money. In a fitting conclusion, the last turbine car produced was a nearly stock-looking 1980 Dodge Mirada.

It's regrettable that the program concluded when it did. According to a project official, an eighth-generation turbine engine, ironically designed for Chrysler's crucial new front-drive K-car compacts and their future variants, was left unfinished. Featuring a single turbine shaft (instead of two), electronic fuel delivery, and an estimated 85 horsepower, it would have been the simplest and likely most cost-effective turbine to mass-produce.

There was also optimism that a new variable-geometry burner could finally solve the NOx issue. However, with time and funding exhausted, this engine never progressed beyond blueprints and a foam prototype.

Thankfully, Chrysler preserved a piece of history by saving 10 of the Ghia-built Turbine Cars from destruction. The remaining vehicles were dismantled under U.S. Customs supervision. This was necessary because import duties on these "foreign" cars had been waived solely for the testing program. Once the program ended, Chrysler had to either return them to Italy or pay substantial fees to retain them in the U.S.

Of the 10 preserved cars, nine have been located. Chrysler retains three, while the other six are housed in various museums.

Today, turbine power holds as much relevance to the automotive future as rumble seats and tailfins, especially with the current focus on hybrid systems and alternative fuels. At least Chrysler's turbine legacy and a few surviving examples remind us of a future that nearly came to pass but ultimately remained out of reach.

To explore more about concept cars and the production vehicles they inspired, take a look at:

- Concept Cars

- Classic Cars

- Consumer Guide auto show reports

- Future Cars