The article How Diesel Engines Operate discusses the four-stroke diesel engines typically found in automobiles and trucks. Meanwhile, the article How Two-Stroke Engines Function focuses on the compact two-stroke engines used in devices like chainsaws, mopeds, and jet skis. Interestingly, diesel engine technology is often integrated with the two-stroke cycle in the massive diesel engines powering locomotives, large vessels, and power generation plants.

In this edition of Mytour, we delve into the world of diesel two-stroke technology and explore the colossal engines that rely on it!

Understanding the Cycle

If you've read How Two-Stroke Engines Work, you're aware that one of the key distinctions between two-stroke and four-stroke engines is the power output. In a two-stroke engine, the spark plug ignites twice as frequently — once per crankshaft revolution, compared to once every two revolutions in a four-stroke engine. This gives the two-stroke engine the potential to generate twice the power of a similarly sized four-stroke engine.

The article on the two-stroke engine further explains that the gasoline engine cycle, which involves mixing and compressing gas and air together, doesn’t align perfectly with the two-stroke method. The issue arises as some unburned fuel escapes each time the cylinder is refilled with the air-fuel mixture. (See How Two-Stroke Engines Work for more information.)

It turns out that the diesel method, which compresses only air before injecting the fuel directly into the compressed air, aligns much better with the two-stroke cycle. As a result, many manufacturers of large diesel engines adopt this approach to produce high-power engines.

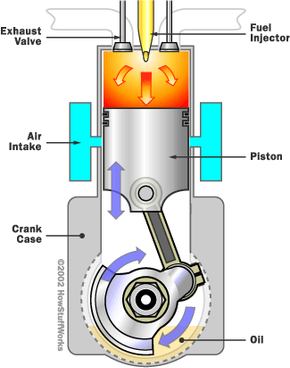

The diagram below illustrates the configuration of a typical two-stroke diesel engine:

At the top of the cylinder, there are usually two or four exhaust valves that open simultaneously. The diesel fuel injector (highlighted in yellow above) is also present. The piston is extended, similar to a gasoline two-stroke engine, allowing it to function as the intake valve. At the bottom of the piston’s stroke, the piston uncovers the air intake ports. The intake air is pressurized by a turbocharger or a supercharger (shown in light blue). The crankcase is sealed and contains oil, much like a four-stroke engine.

The two-stroke diesel cycle works as follows:

- When the piston reaches the top of its stroke, the cylinder is filled with highly compressed air. Diesel fuel is injected into the cylinder and ignites instantly due to the intense heat and pressure. This process mirrors what is explained in How Diesel Engines Work.

- The combustion of the fuel generates pressure that forces the piston down. This is the power stroke.

- As the piston approaches the bottom of its travel, all the exhaust valves open. The exhaust gases quickly exit the cylinder, relieving the pressure.

- When the piston reaches the bottom, it uncovers the air intake ports. Pressurized air enters the cylinder, pushing out the remaining exhaust gases.

- Once the exhaust valves close, the piston begins to travel upward again, covering the intake ports and compressing the fresh air charge. This is the compression stroke.

- As the piston nears the top of the cylinder, the cycle begins again with step 1.

From this explanation, you can spot a major difference between a diesel two-stroke engine and a gasoline two-stroke engine: in the diesel version, only air fills the cylinder, unlike the gas and air mixture in a gasoline engine. This eliminates the environmental issues that a gasoline two-stroke engine faces. However, a diesel two-stroke engine requires a turbocharger or a supercharger, which makes it impractical for use in something like a chainsaw due to the high cost.

General Motors EMD Engines

The General Motors EMD engine series exemplifies the two-stroke diesel engine family. First introduced in the 1930s, these engines power many of the diesel locomotives across the United States. The EMD line has evolved through three main series: the 567, 645, and 710 series. The numbers indicate the cubic inches per cylinder, with most engines having 16 cylinders, resulting in a total displacement around 10,000 cubic inches! To put this into perspective, a 5-liter (305 cubic inches) engine is considered large for a car, so these EMD engines are truly massive!

Below are some specifications for the EMD 645E3 engine:

Cylinder diameter - 9.0625 inches

Piston stroke length - 10 inches

Displacement per cylinder - 654 cubic inches

Number of cylinders - 16 or 20

Compression ratio - 14.5:1

Exhaust valves per cylinder - 4

Engine weight -

- 16 cylinders: 34,526 pounds / 15,661 kg

- 20 cylinders: 40,144 pounds / 18,209 kg (The oil pan alone weighs more than a ton!)

Idle speed - 315 revolutions per minute (rpm)

Full speed - 900 rpm

One of these engines typically boasts a horsepower rating of 4,300 hp!