Reel mowers help reduce noise and environmental pollution around your home.

iStockphoto.com/Brian Carpenter

Reel mowers help reduce noise and environmental pollution around your home.

iStockphoto.com/Brian CarpenterKey Insights

- Reel mowers, which have been around since the early 1800s, feature a straightforward design with a rotating bladed reel mounted on a cart, using wheel movement to precisely trim grass.

- Once bulky and difficult to use, these mowers have become lighter and more user-friendly over time, with some modern versions incorporating drive chains like those found on bicycles.

- Though gas and electric mowers dominate, manual reel mowers continue to appeal for their eco-friendliness and mechanical simplicity, making them an excellent choice for small-scale lawn care.

On a sunny summer afternoon, you step outside, close your eyes, and embrace the sounds of the season: birds singing, bees buzzing, and the hum of lawnmowers. It wasn't always like this. Hard to imagine, but there was once a time when mowing the lawn didn’t involve pushing or driving a small, gas-powered engine across your yard.

The original lawn mowers were manual reel mowers, also referred to as cylinder mowers. To use one, a person simply had to push it across the lawn, and the rotating wheels would turn a cylinder with sharpened blades to cut the grass.

The 20th century saw the development of gas-powered reel mowers and gas-powered rotary mowers. However, not everyone embraced the new technology. Many people continued using manual reel mowers, and many still prefer them today.

Despite the technology remaining relatively unchanged for over a century, manual reel mowers still offer several advantages over their gas-guzzling and rotary counterparts. Manual reel mowers:

- Are more affordable than gas-powered mowers.

- Are safer than rotary mowers.

- Require minimal maintenance.

- Are eco-friendly.

- Scoop and trim grass blades rather than tearing them, unlike rotary mowers.

- Operate quietly.

- Are easy to store and transport.

- Don't stir up dust or release harmful emissions.

- Don't scatter debris around your yard.

The downside? You’ll have to trade speed for effort. Pushing a manual reel mower across the lawn, as well as powering its blades, requires physical exertion. The force needed is generally similar to that of a larger rotary mower. However, taller grass demands more effort to mow, and tall weeds may be nearly impossible to cut without first using a sling blade.

How did 19th-century inventors first adapt textile mill technology for lawn care? Find out on the next page.

Reel Mower History

This reel mower ad from the 1870s emphasizes the mower's light weight and user-friendly design, showcasing how even a young girl can operate it.

Transcendental Graphics/Hulton Archive/Getty Images

This reel mower ad from the 1870s emphasizes the mower's light weight and user-friendly design, showcasing how even a young girl can operate it.

Transcendental Graphics/Hulton Archive/Getty ImagesThe history of reel mowers spans centuries. Before the early 1800s, maintaining a lawn typically relied on grazing animals or manual tools like scythes, swing blades, and gardening shears. For those willing and able to tend to their lawns, this method worked well enough. But the 19th century was a time of rapid transformation. Europe was in the midst of the Industrial Revolution, marked by groundbreaking technological advancements and discoveries.

Throughout the 1800s, inventors made remarkable progress, from steam power innovations to mass production of machine parts. Many of their efforts focused on improving essential industries like coal mining, textile manufacturing, and transportation. But new technologies often found their way into even the most everyday tasks.

British engineer Edwin Beard Budding made a significant link between emerging technology and everyday use. He observed a machine at a local textile mill that used a bladed reel or cutting cylinder to trim cloth. Recognizing the potential for applying this technology to lawn care, he partnered with engineer John Ferrabee. Together, in 1830, they created the world’s first lawn mower.

The two engineers took the bladed reel, mounted it onto a wheeled cart, and designed a system of gears to transfer the rotation of the wheels to the reel. Although these mowers were heavy, cast-iron machines, after the patents held by Budding and Ferrabee expired, other inventors began refining the design. These improvements made the mowers lighter and easier to push. Some even replaced the gears with drive chains similar to those used in bicycles.

In the 1890s, inventors experimented with adding power sources to reel mowers. They tested both horsepower and steam power before small-engine technology advanced enough to become the new standard. Today, most gas mowers for home lawns are rotary mowers, which use a horizontal, fan-shaped blade. While gas-powered reel mowers are still in use, many are large, tractor-powered machines designed for maintaining sports fields and farms.

Although gas- and electric-powered mowers have continued to evolve over the years, the fundamental design of the manual reel mower has remained unchanged. On the following page, we will explore the various components of the reel mower.

Reel Mower Parts

How Things Work

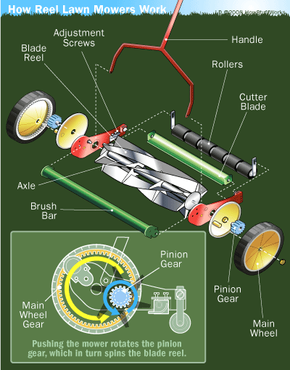

How Things WorkManual reel mowers are relatively straightforward machines, relying on just a few moving parts and the fundamental principle of force. The basic structure of the mower consists of a small cart with a long handle. Most reel mowers have two main wheels attached to a single axle, with either a bar of rollers or a set of smaller, secondary wheels at the rear. The rear roller or wheels serve to provide balance, while the primary wheels create the motion needed to rotate the mower's cutting cylinder.

The best way to grasp how reel mower parts function is to follow the path of force as it moves through the mower.

- A person pushes the handlebars, applying force.

- The force moves down the handle, propelling the mower forward on its wheels.

- As the axle turns, it drives a pair of gears. The first gear is larger than the smaller pinion gear. When a larger gear transfers its rotation force, or torque, to a smaller gear, the torque increases. This is why the blades of a reel mower spin much faster than the wheels. To dive deeper into the physics behind this, check out How Gear Ratios Work.

The brush bar at the front of the mower bends tall grass, guiding it into the spinning cylinder blades. While the reel may seem impressive as it spins, it doesn't actually cut the grass by itself. The cutting happens where the rotating edges meet the stationary cutter bar at the back of the mower. Think of it as the meeting point of the two blades of a pair of scissors. The cylinder scoops up the grass and positions it for cutting by the cutter bar, much like a barber uses a comb to arrange hair for a trim.

Most of the grass clippings end up falling behind the mower, which allows many models to be equipped with a collection tray or bag. This is a major difference between reel mowers and rotary mowers, as the fan-like blades of the latter actually tear the grass, potentially exposing the plants to diseases [source: University of Tennessee].

Does this sound like the perfect tool for your garden shed? Flip to the next page to discover how to properly use and maintain a reel mower.

Investing in a manual reel mower can help you save quite a bit. While a brand new, gas-powered rotary mower can set you back several hundred dollars, a new manual reel mower typically costs between $70 and $150.

Maintaining Reel Mowers

Reel mowers require minimal upkeep beyond the need for regular sharpening.

Saul/Hulton Archive/Getty Images

Reel mowers require minimal upkeep beyond the need for regular sharpening.

Saul/Hulton Archive/Getty ImagesManual reel mowers are a sustainable and eco-friendly choice, but they tend to be slower compared to using a gas mower. Because of this, manual reel mowers are best suited for lawns up to 8,000 square feet (around 743 square meters), which is roughly 0.18 acres [source: Reel Mower Guide]. You also need to be ready to mow your lawn regularly, typically once a week in the summer. If the grass grows too tall, using a reel mower can become very difficult, or even impossible. After several rainy weeks, you might find yourself needing a gas mower or a swing blade.

Since the gears in a manual reel mower cause the blades to spin faster than the wheels, there's no need to rush to maintain blade speed. However, the person pushing the mower is still responsible for providing all the power. A steady, moderate pace is required to keep the reel turning. Aside from this, using a reel mower is quite similar to using a gas-powered push mower. Knowing your grass type and understanding the required mowing height and care will help you maintain your lawn effectively.

Maintaining reel mowers is straightforward. When properly maintained, reel mowers can serve you for many years. There's no need for oil changes or tune-ups. The essential rules for maintaining a reel mower are:

- Clean the blades regularly.

- Wash off excess grass clippings.

- Store the mower in a dry place to prevent rust.

Sharpening the blades is easy with a grinding stone, grinding paste, and some newspaper. The grinding stone is essentially a rough rock file, and the grinding paste has a gritty texture like wet sand. Reel mower sharpening kits usually come with both. Start by using the grinding stone to smooth out any nicks or burrs. Then, apply the grinding paste to the reel blades and cutter bar. Turning the reel backward, the gritty paste will file the edges of the blades, sharpening them. Finally, clean the blades and test the cut on some newspaper to ensure the reel and cutter bar are aligned properly. If not, simply adjust the blade settings.

With growing concerns over pollution and increasing gas prices, reel mowers are experiencing a resurgence in popularity. Today, both new and second-hand models are easily found at most hardware stores, lawn care retailers, and online marketplaces.