Weather stripping can help cut down on your energy expenses AvailableLight / Getty Images

Weather stripping can help cut down on your energy expenses AvailableLight / Getty ImagesSoaring energy prices can turn a chilly, drafty home into a costly burden. Sealing your house with efficient weather stripping can keep you cozy all winter and lower your energy bills.

If your front door had a 6-inch-square hole in the center, you'd definitely take action to seal it. Yet, many homes have a 1/8-inch-wide gap around the door, which causes the same amount of energy loss as that hole. Allowing these gaps is like throwing money away. Fortunately, weatherstripping can cut your heating and cooling costs by up to 30% while also blocking drafts that lead to discomfort.

Determining if your home needs weather stripping is simple. On a windy day, if you feel cold air around doors and windows, the answer is clear. If you're unsure, you can simulate a windstorm at the exact area you suspect air leakage. Stand outside with a handheld hair dryer, and have a helper move their hands around the door or window frame as you move the dryer.

You might find that your doors and windows are sealed tightly. Or perhaps you’ll notice that some are sealed on three sides but need attention on the fourth side. Most likely, you'll discover that there are several drafty spots in your home that could benefit from weather stripping.

In this guide, we'll walk you through how to install weather stripping in various areas of your home. We’ll also discuss the different types of weather stripping, starting with that as our first topic of focus.

Various Types of Weather Stripping

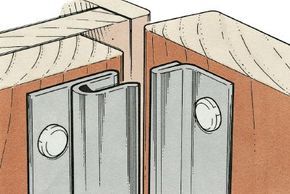

Interlocking metal weather stripping offers a strong seal as long as the pieces align correctly. Installation can be challenging, and ongoing maintenance requires careful inspection for any bent pieces.

©2006 Publications International, Ltd.

Interlocking metal weather stripping offers a strong seal as long as the pieces align correctly. Installation can be challenging, and ongoing maintenance requires careful inspection for any bent pieces.

©2006 Publications International, Ltd.

There are various types of weather stripping because different situations require different materials. Homeowners have several options, with most of them suitable for both doors and windows.

Pressure-sensitive adhesive-backed foam is the simplest weather stripping to apply and is also budget-friendly. It comes in rubber and plastic varieties, in rolls of different lengths and thicknesses. When compressed by a door or window, the foam creates an airtight seal. Additionally, these strips help reduce slamming noise due to their cushioning effect. Though not a permanent solution, it typically lasts between one and three years. Avoid painting over this material, as it can damage the foam’s elasticity.

Spring-metal strips (either V-shaped or single) are available in finishes such as bronze, copper, stainless steel, and aluminum. These weatherstripping rolls come with the necessary brads for installation. While the installation process might seem straightforward, it requires some patience.

Self-sticking spring metal features a peel-and-stick backing. These are similar to the standard spring-metal strips, but they are much easier to install.

Felt is a traditional and cost-effective option. It comes in various widths, thicknesses, qualities, and colors (such as brown, gray, and black). Felt strips are typically nailed in place, but versions with pressure-sensitive adhesive backing are also available.

Serrated metal is a type of weather stripping that combines a felt or vinyl backing with the durability of metal. Most manufacturers package serrated-metal weather stripping in rolls, and they include the necessary brads for installation.

Tubular gasket weather stripping is made of highly flexible vinyl and is typically used on the exterior, as it conforms easily to uneven surfaces. Available in white and gray, it should not be painted, as the paint will stiffen the tube and reduce its flexibility.

Foam-filled tubular gasket weather stripping features a foam core within the tubular gasket, offering enhanced insulation and strength. This type holds its shape better than the hollow-tube version, but like the standard one, it should not be painted.

Interlocking metal weather stripping consists of two pieces that fit together to form a seal. One piece attaches to the door, while the other is fixed to the doorframe. Installation generally requires precise cutting (rabbeting), so professional-level expertise is often needed. For maintenance, straighten any bent parts using a screwdriver, pliers, or a putty knife. Casement window gaskets are vinyl channels that slip over the lip of the frame without the need for adhesives or tools, except for scissors to trim to the correct length. This type is generally available in gray.

Jalousie gaskets are transparent vinyl tracks that can be trimmed to fit over the edges of jalousie louvers. They snap into place, creating a secure friction fit.

Turn to the next page to discover how to effectively use all these types of weather stripping.

Steps to Install Weather Stripping

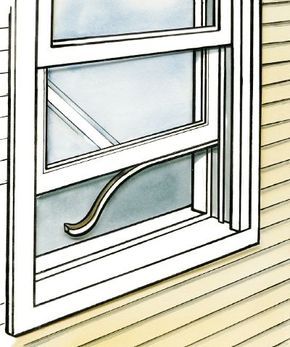

©2006 Publications International, Ltd. Apply pressure-sensitive weather stripping only to the parts of a wooden window that are free from friction.

©2006 Publications International, Ltd. Apply pressure-sensitive weather stripping only to the parts of a wooden window that are free from friction.Most homes have some degree of air leakage around doors and windows. Installing weather stripping to seal these gaps can significantly reduce drafts and save on heating and cooling costs. In this section, we’ll explore how to install the different types of weather stripping.

Pressure-Sensitive Foam

Pressure-sensitive adhesive-backed foam is one of the easiest and most affordable weather stripping options to install. Available in both rubber and plastic, it comes in rolls with various lengths and thicknesses. This type of weather stripping should only be applied to the friction-free areas of a wooden window, such as the lower sash or the top of the upper sash. If applied too tightly between the upper and lower sashes, the window's movement could cause it to loosen.

To install pressure-sensitive types of weather stripping: Pressure-Sensitive Felt Felt is a classic, cost-effective option available in different widths, thicknesses, qualities, and colors (brown, gray, and black). To use pressure-sensitive felt, follow the same method as you would for foam. Felt strips may also be found without adhesive backing, but these require nailing to secure them in place.

These are the tools you'll need to apply pressure-sensitive weather stripping:

- Dish detergent

- Clean rags

- Petroleum jelly

- Scissors

How to Install Spring-metal and Other Weather Stripping Types

©2006 Publications International, Ltd. Use a screwdriver to flare the edge of a spring-metal strip, ensuring a tight and secure fit.

©2006 Publications International, Ltd. Use a screwdriver to flare the edge of a spring-metal strip, ensuring a tight and secure fit.Spring-metal strips, available in V-shaped or single forms, come in finishes like bronze, copper, stainless steel, and aluminum. Most manufacturers package them in rolls, including the necessary brads for installation. While the installation may seem straightforward, it does require some patience.

Spring-metal weather stripping fits into the window tracks. Each strip should be about 2 inches longer than the sash so the end remains visible when the window is closed. Here's how to install spring-metal weather stripping:

Step 1: Position the vertical strips with the flared edge facing outward. The center strip should be mounted to the upper sash with the flare directed downward, while the horizontal strips should be attached to the top of the upper sash and the bottom of the lower sash, with the flared edge facing out. Use snips to cut the spring-metal weather stripping to the appropriate length, ensuring room for the window pulley mechanism.

Step 2: Secure the strips to the window frame. Position each strip carefully, taking note of any hardware like hinges or locks that may cause interference. Trim the metal as necessary. Then, cut the ends of the strips at an angle where the vertical and horizontal strips meet. Insert one nail at the top and one at the bottom of each strip. Avoid over-nailing and do not drive the nails fully in. Some vertical strips may not have nail holes, so you may need to create pilot holes using an ice pick or awl.

Step 3: Ensure that the strips are aligned properly and in the correct position. Drive a nail into the center of each strip, but again, only partially. Place additional nails between the initial ones. To avoid damaging the strip, never drive the nails in completely using a hammer. Instead, use a nail set to drive the nails flush with the surface.

Step 4: Use a screwdriver to flare out the edge of each strip, ensuring a snug and secure fit.

Here are the tools you'll need to apply spring-metal weather stripping:

- Tin snips

- Hammer

- Nails

- Awl or ice pick

- Nail set

- Screwdriver

Self-Sticking Spring Metal

Self-sticking spring metal comes with a peel-and-stick backing. These strips are similar to standard spring-metal ones, but they are much easier to install. This type of weather stripping works best on wood-framed windows. Here's how to install self-sticking spring metal weather stripping:

Step 1:

Measure the strips and cut them to the correct size for the window. Then, clean the area where the strips will be applied.

Step 2: Position the strips without removing the backing paper. Mark areas that need trimming, such as where hardware is located and where the vertical and horizontal strips meet.

Step 3: Starting at one end, peel off the backing and press the strip into place, continuing to peel and press as you work your way to the other end.

Felt Weather Stripping

Felt is a long-standing, cost-effective option for weather stripping. It is available in a variety of sizes, thicknesses, qualities, and colors, including brown, gray, and black.

Although felt strips may not be the most visually appealing for sealing gaps in wooden-frame windows, they can still be used effectively in certain areas. Felt strips are ideal for sealing the bottom of the lower sash, the top of the upper sash, and the interior side of the upper sash, where they act as horizontal gaskets. Here's how you can install felt weather stripping:

Step 1: Measure and cut the felt to fit the window. Remember that felt can be shaped to fit around corners. Press the material firmly against the gap.

Step 2: Start by nailing the ends of each strip, but don't drive the nails flush with the surface; leave some room to pull them out. Begin at one end, securing the felt with nails spaced 2 to 3 inches apart, pulling the felt tight as you go. If the felt becomes loose when you reach the other end, remove the nails, tighten it, and trim any excess.

Note: It's best to perform this task on a warm day, as the adhesive bonds better when applied at temperatures of at least 60 degrees Fahrenheit.

Pressure-Sensitive Felt

Follow the same procedure used for attaching pressure-sensitive foam weather stripping.

Here’s a list of tools necessary for applying self-sticking spring metal weather stripping:

- Tape measure

- Pencil

- Scissors

- Dish detergent

- Clean rags

Tubular and Foam-Filled Gasket Weather Stripping

Typically, the only type of weather stripping that can be used on metal windows is the pressure-sensitive variety. Screws would penetrate the metal and prevent the window from moving. To install, apply weather stripping to the top of the upper sash (if movable) and to the bottom of the lower sash. These areas are usually the only spots on metal windows that allow for airflow. For any additional gaps, apply a vinyl tubular gasket using a special adhesive designed to bond vinyl to metal.

Tubular gasket weather stripping is crafted from highly flexible vinyl. It is typically used on the exterior, where it easily adapts to uneven surfaces. Foam-filled tubular gasket weather stripping has a foam core inside the tube, adding extra insulation and durability. Neither type should be painted.

Tubular weather stripping is not the most aesthetically pleasing. It works best when placed on the outside of the window. If the window is easily accessible from the outside, tubular weather stripping can be a great option. It can also enhance the performance of existing weather stripping. Here's how to apply tubular and foam-filled gasket weather stripping:

Step 2: Carefully position each strip and secure one end with a nail. Place nails every 2 to 3 inches apart, ensuring the weather stripping is tight before securing each nail. Most metal windows have grooved edges where metal flanges interlock, negating the need for weather stripping. However, gaps can sometimes form, requiring you to apply weather stripping in those areas.

Next, we'll cover methods for applying different types of weather stripping to doors and sliding windows.

Here are the tools required to apply tubular and foam-filled gasket weather stripping:

- Tape measure

- Pencil

- Scissors

- Hammer

- Nails

How to Apply Weather Stripping to Sliding Windows and Doors

Applying weather stripping to sliding windows and doors can be tricky. In this section, we will guide you through overcoming the various obstacles that come with these tasks.

Installing Weather Stripping on Sliding Windows

Sliding windows, which slide horizontally, are available in both wood and metal frames. For wooden frames, weather-strip them in the same way as you would for a double-hung window that has been turned sideways. If only one sash moves, weather-strip the movable one and apply caulk to the stationary sash. For metal frames, follow the same steps as for weather-stripping typical metal windows.

Special gaskets are available for sealing the gaps in jalousie and casement windows. For jalousies, measure the edge of the glass louver, trim the gasket to fit using scissors, and snap it into place. For casement windows, measure the frame's edges, cut gasket strips to size, miter the ends where they meet, and position the strips over the frame's lip.

Double-hung wooden windows typically require weather-stripping, although if the top sash is rarely opened, you can address air leakage by caulking to seal any gaps. It might be beneficial to use multiple types of weather stripping to complete the task. Make sure to follow the correct installation techniques for each type of weather stripping.

Installing Weather Stripping on Doors

Doors are prone to air leaks on all four edges. In fact, a typical door has more gaps than an ill-fitting window. Since doors don't slide in grooves like windows, cracks around them are usually larger. Weather stripping on doors helps seal these gaps, eliminate drafts, and can lead to reduced heating and cooling costs. This article will explore the various door weatherstripping options and how to install them.

Before applying weather stripping, check the door to ensure it fits correctly in the frame. Close the door and inspect it from the inside. Look for any uneven gaps between the door and the frame on all sides and across the top. While the gap doesn’t need to be identical all around, if the door is crooked in the frame, the weather stripping could prevent it from opening or closing properly. Significant gaps will make it difficult to apply weather stripping effectively.

Most door issues stem from the hinges. Start by opening the door and tightening all the hinge screws. Even slightly loose screws can cause the door to sag. If the screw holes have worn out and are too large to hold the screws, replace them with larger screws that fit in the hinge's countersunk holes. If larger screws don't fit, fill the holes with toothpicks dipped in glue and trim them flush with the surface. This will provide fresh wood for the screws to grip.

At times, the door may need to be planed to prevent it from binding. Typically, you can plane the top while the door is still in place. Always plane toward the center to avoid splintering the edges. If you need to plane the sides, remove the door from its hinges, plane the hinge side, and always plane toward the edges.

Spring metal is a popular choice for door weather stripping. It works effectively when installed properly and remains invisible when the door is closed. Many door kits include a triangular piece that fits next to the striker plate on the jamb.

Applying Spring-metal Strips

Spring-metal strips (V-shape or single) are offered in finishes such as bronze, copper, stainless steel, and aluminum. These strips are typically sold in rolls, accompanied by brads for installation. Although installing this type of weather stripping may seem straightforward, it requires attention to detail. Here's how to apply spring-metal weather stripping around a door:

Step 1: Measure and cut the spring-metal strips to the appropriate size.

Step 2: Position the side strips so that the flared flange nearly touches the door stop. Trim any excess metal to make room for hinges, locks, or other hardware as needed.

Step 3: Drive one nail into the top and one into the bottom of each side strip. Do not insert more nails or fully drive in the top and bottom nails. If the strips don’t have pre-punched holes, create pilot holes using an ice pick or awl. Verify that the side strips are straight and in the correct position.

Step 4: Drive a nail into the center of the side strip but leave it slightly out. Then, insert nails at regular intervals between the ends. To prevent damaging the strip, do not hammer the nails completely in—use a nail set to drive them flush. Repeat this step for the other side strip.

Step 5: Install the top strip last, trimming it to fit with a mitered cut. Use a screwdriver to flare out the edges of each strip for a tighter fit.

Here’s a list of tools required to install spring-metal strips around doors:

- Tape measure

- Pencil

- Tin snips

- Hammer

- Nails

- Awl or ice pick

- Nail set

- Screwdriver

Applying Self-Sticking Spring Metal Around Doors

Self-adhesive spring metal features a peel-and-stick backing, making it easier to install than regular spring-metal strips. Although similar in function to traditional spring metal, it simplifies the process. You can use self-sticking spring metal in the same places as standard spring metal. To install it around a door, follow these steps:

Step 1: Clean the surface where the strips will be applied. Then, use tin snips to measure and cut the strips to the appropriate size.

Step 2: Position the strips without removing the backing paper. Mark areas where trimming is necessary, such as around hardware and where the vertical and horizontal strips meet.

Step 3: Remove the backing from one end of the strip and press it into place. Continue peeling off the backing and pressing the strip firmly as you work your way toward the other end.

To install self-sticking spring metal around doors, gather the following tools:

- Dish detergent

- Clean rags

- Tape measure

- Pencil

- Tin snips

Applying Pressure-sensitive Foam

©2006 Publications International, Ltd. To seal the top and sides of a door, use adhesive-backed foam weather stripping. Simply peel off the backing and apply the strip along the edges.

©2006 Publications International, Ltd. To seal the top and sides of a door, use adhesive-backed foam weather stripping. Simply peel off the backing and apply the strip along the edges.Pressure-sensitive foam with adhesive backing is the simplest type of weatherstripping to install and is also very affordable. It is available in both rubber and plastic versions, with rolls that vary in length and thickness. When compressed by a door or window, the foam creates an airtight seal.

Additionally, these strips provide cushioning that dampens the sound of slamming doors. While not a permanent solution, adhesive-backed foam weatherstripping can last between one and three years.

To apply pressure-sensitive foam weather stripping around doors, follow these steps:

Step 1: Choose a warm day for the task if possible. The adhesive bonds better when the temperature is at least 60°F.

Step 2: Clean the area where the weather stripping will be applied using detergent and water. Ensure the surface is free from any dirt or grease. If any old adhesive from previous weather stripping remains, remove it using petroleum jelly. Wipe the surface dry with rags.

Step 3: Cut the foam strip to the desired length using scissors, but leave the backing paper in place for now.

Step 4: Starting at one end, carefully peel off the backing paper while pressing the sticky foam into place. If the backing is difficult to remove initially, gently stretch the foam until the seal between the foam and backing breaks.

Step 5: Attach the strips to the doorjamb on the hinge side.

©2006 Publications International, Ltd. Apply the strips of pressure-sensitive foam to both the hinge side of the doorjamb and the doorstop. The adhesive backing on the foam will create a strong bond only if the surface is clean and free from grease.

©2006 Publications International, Ltd. Apply the strips of pressure-sensitive foam to both the hinge side of the doorjamb and the doorstop. The adhesive backing on the foam will create a strong bond only if the surface is clean and free from grease.Step 6: Place the remaining two strips onto the doorstop. If the door catches the weather stripping while closing, trim the top piece of foam on the hinge side. You can also use serrated-metal weather stripping, which often includes a felt-strip insert along the length of the groove, to seal air gaps around doors. To install this type, measure the required length, cut the material with tin snips or heavy-duty scissors, and then secure each strip with nails at both ends, one in the center, and additional nails every 2 to 3 inches along the strip.

Here are the tools you'll need to install pressure-sensitive foam weather stripping around doors:

- Dish detergent

- Clean rags

- Petroleum jelly

- Scissors

Creating A Weathertight Threshold

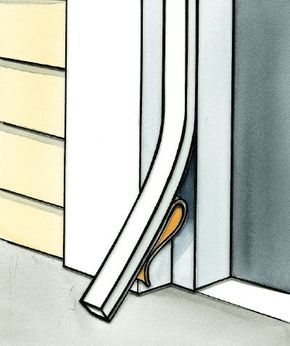

©2006 Publications International, Ltd. A door sweep is an effective way to seal any gap between the bottom of the door and the threshold. These sweeps can be made from a combination of materials such as wood and felt, wood and foam, or metal and vinyl, all of which work well to block drafts.

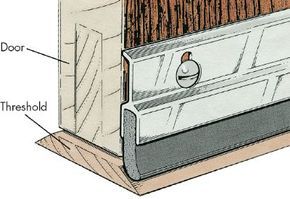

©2006 Publications International, Ltd. A door sweep is an effective way to seal any gap between the bottom of the door and the threshold. These sweeps can be made from a combination of materials such as wood and felt, wood and foam, or metal and vinyl, all of which work well to block drafts.The gap at the bottom of the door is treated differently than the gaps on the sides and top. The raised strip along the bottom of the door that rests on the floor is called the threshold.

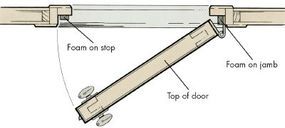

Many metal thresholds include a flexible vinyl insert that forms a tight seal when the door closes against it. Other types feature an interlocking system, with one piece on the floor and another attached to the bottom of the door, creating a weathertight seal.

Typically, the threshold with a flexible vinyl insert is the easiest to install. While interlocking systems are highly effective, they require a precise fit to work properly.

Wooden thresholds can wear out over time and may need replacement. Replacing a threshold is a simple process, and there are many options available, most made of aluminum and designed to fit standard door widths. If your door is non-standard in size, you can easily trim an aluminum threshold with a hacksaw. Here's how to replace a threshold:

Step 1: Begin by removing the old threshold. If it is made of wood, there are a couple of ways to take it out. Typically, you can pry it up after removing the doorstops with a small flat pry bar or putty knife. Proceed carefully to avoid damage. If the jamb itself is resting on the threshold, you will need to saw through the threshold at both ends.

To remove the threshold, use a backsaw placed directly against the jamb and saw through it, making sure not to damage the floor. Once the cuts are made, the threshold should be easy to pry up. If prying doesn't work, you can use a chisel and hammer to break it apart. Metal thresholds are often secured with screws hidden under vinyl inserts, which, when removed, will allow the threshold to lift off easily.

Step 2: Install the new threshold by driving screws through the metal piece and into the floor. If you prefer not to use an aluminum threshold, you can cut a wooden replacement using the old threshold as a template.

Step 3: Attach a door sweep to seal the gap. Most sweeps are affixed to the inside of the door with nails or screws. Cut the sweep to the appropriate length, close the door, and tack both ends of the sweep in place. Afterward, install the remaining nails or screws. If you're using screws, be sure to drill pilot holes first.

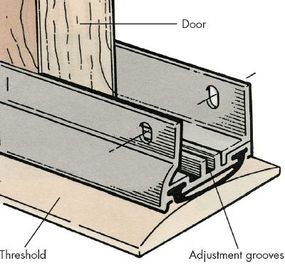

©2006 Publications International, Ltd. A bottom sweep slides over the door's bottom edge. Its adjustable grooves allow it to fit any door thickness.

©2006 Publications International, Ltd. A bottom sweep slides over the door's bottom edge. Its adjustable grooves allow it to fit any door thickness.Certain door sweeps fit underneath the door, wrapping around the bottom edge. Another version attaches to the outside, with a part that flips upwards to clear the threshold when the door opens. Once the door is closed, this part flips back down, creating a seal against the threshold. You can adjust this type of sweep to ensure a perfect fit.

Weatherproofing your doors – and the rest of your home – is a great way to stay comfortable during harsh weather. The best part is that you don't need to hire a professional to make these improvements to your home.

Publications International, Ltd.

Here are the tools you'll need to install a weathertight threshold around doors:

- Small flat pry bar or putty knife

- Backsaw

- Chisel

- Hammer

- Screwdriver

- Replacement threshold

- Door sweep

- Tape measure

- Pencil

- Nails

- Drill