Often, a loose joint can be repaired with just some glue. Use a glue injector to apply the adhesive, then clamp the joint securely until the glue has completely dried. Image: vitranc / Getty Images

Often, a loose joint can be repaired with just some glue. Use a glue injector to apply the adhesive, then clamp the joint securely until the glue has completely dried. Image: vitranc / Getty ImagesThe structural issues in wooden furniture can be categorized into three main aspects: the material itself, the assembly process, and how it functions.

The material is at fault when a piece is damaged, warped, or missing. The construction is the issue when joints loosen or parts are improperly fitted. The way a furniture piece works relies on both material and craftsmanship, and any functional problems can always be traced to one or both. While no amount of work can transform a subpar piece into something exceptional, mastering a few basic repair methods will allow you to maintain your wooden furniture in excellent condition. This article will explore some of those techniques.

Repairing Loose Joints

When a joint becomes loose, you face two issues: the immediate functional problem and the long-term strain it causes on the rest of the structure. A joint that’s not fixed right away may not fail immediately, but it will gradually weaken the surrounding joints. In just a week, one shaky leg can turn into two. To avoid minor structural issues from escalating into bigger problems, it’s crucial to address loose or detached joints without delay.

Adhesive Repair

The simplest solution is often the most effective, whether you’re repairing or refinishing. If you discover a loose joint, start by tightening any screws (if there are any). Then, attempt to fix the joint with an adhesive: plastic resin, epoxy, or resorcinol. Use a glue injector to force the adhesive into the joint, and, if possible, move the joint around to help spread the adhesive. Clamp the joint for around two days to allow the adhesive to fully set. If possible, reinforce the glued joint with a glue block, as described below.

Once the joint has been glued and the piece is back in use, check it again in a few weeks. If it becomes loose once more, regluing won’t offer a permanent solution. In such cases, you’ll need to reinforce the joint, secure it differently, or completely rebuild it.

Reinforcing Joints with Glue Blocks and Steel Braces

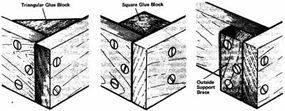

Glue blocks, the original method of reinforcing furniture, are solid wood pieces used to strengthen corner joints and offer additional support. While steel corner plates and angle braces serve the same purpose, they can negatively impact the furniture's appearance and reduce its value. For this reason, glue blocks remain an essential tool in furniture repairs. Valuable items, antiques, and high-quality reproductions should always be repaired with glue blocks rather than steel braces whenever possible.

Glue blocks for corner reinforcement come in square or triangular shapes. Square blocks are typically used as outside support braces or for long joints, such as the inside corners of drawers, where triangular blocks would be difficult to cut. However, triangular glue blocks are usually the better choice in most cases.

Glue blocks can be made from any square wood stock, but hardwood is generally preferred. To create a glue block, simply cut a square piece of wood diagonally in half. The larger the piece of wood, the more surface area there will be for gluing. The length of the block will vary based on the project, but 2 inches is typically sufficient. For strengthening chair and table legs, triangular braces should be cut from 1-inch nominal boards as large as needed. When cutting, be sure to make a diagonal cut or notch at the right-angle corner to fit around the leg. For braces, 1 x 2 lumber works well.

Glue blocks, the original furniture reinforcement method, are used to strengthen corner joints and provide extra support. Triangular glue blocks (left) are generally preferred for corner braces. Square glue blocks are used for long joints where cutting a triangle would be difficult (center), or as external support braces (right). Whenever possible, glue blocks should be cut from hardwood.

Glue blocks, the original furniture reinforcement method, are used to strengthen corner joints and provide extra support. Triangular glue blocks (left) are generally preferred for corner braces. Square glue blocks are used for long joints where cutting a triangle would be difficult (center), or as external support braces (right). Whenever possible, glue blocks should be cut from hardwood.To attach a triangular glue block, apply adhesive to both right-angle edges. Position the block in the corner and twist it slightly to evenly spread the glue on the surfaces that will bond. For smaller glue blocks, you can secure them with nails driven through the block and into the furniture frame. Be sure to drill pilot holes for the nails to avoid splitting the wood. To reinforce chair and table braces, drive three screws through the block and into the frame—one directly into the corner and two angled into each side of the block. Remember to predrill the screw holes for both the block and the frame.

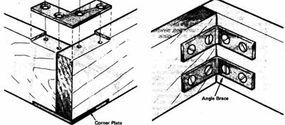

In some cases, a corner joint is secured with a steel bracket instead of a glue block. If the leg is loose, first check that the nut holding the bracket is tightened properly. If tightening the nut doesn’t solve the issue, and the bracket is seated in notches in the frame, it may not be positioned correctly. Remove the nut, reposition the bracket, and then secure the nut again.

Gluing and bracing may not always be enough to fix a loose joint, especially in more complex situations. In such cases, you’ll need to learn advanced repair techniques, which are covered in the next section.

Steel corner plates (left) and angle braces (right) are frequently used to reinforce weak joints, particularly in lower-cost furniture. However, because they can negatively affect the appearance and value of the piece, they should never be applied to valuable or antique furniture.

Steel corner plates (left) and angle braces (right) are frequently used to reinforce weak joints, particularly in lower-cost furniture. However, because they can negatively affect the appearance and value of the piece, they should never be applied to valuable or antique furniture.Resecuring and Rebuilding Loose Joints

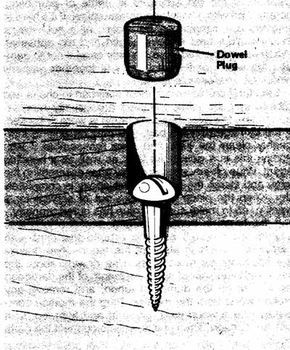

A loose joint can sometimes be secured by driving a long screw coated with glue into the joint. Cover the screw head with a dowel plug, then refinish the frame to restore its appearance.

A loose joint can sometimes be secured by driving a long screw coated with glue into the joint. Cover the screw head with a dowel plug, then refinish the frame to restore its appearance.Some loose joints in furniture may require extra care to ensure they are structurally solid. While resecuring or rebuilding a joint may take more time, you can achieve either solution by applying advanced repair techniques.

Resecuring with Screws and Glue

If disassembling a joint is difficult, you may be able to fix it by using a long screw. Begin by aligning the joint and drilling a pilot hole for the screw. Next, enlarge the top of the pilot hole to allow space for a dowel plug to cover the screw head. Coat the screw with glue and drive it into the joint, pulling the pieces tightly together. Before tightening the screw, apply adhesive into the loose joint to help reinforce it. Then, tighten the screw securely.

To cover the screw head, cut a dowel (wooden peg) to fit the enlarged hole. It should be slightly longer than the hole, so it protrudes slightly above the surface of the frame. Insert the dowel plug with glue, ensuring the end of the dowel is flush with the screw head. Allow the glue to dry completely, then carefully trim the dowel flush with the surface and sand it smooth. You may need to refinish the frame so the dowel blends in. To create a consistent look, consider installing false dowel plugs at the other joints, giving the frame a handmade pinned or pegged appearance.

The screw and dowel method can also be effective for repairing loose rungs and backs, provided that the pieces are large enough to accommodate the screw and dowel. Smaller components like turnings and slats may crack if a screw is driven into them.

For the most durable screw-reinforced joint, the screw should be driven into a dowel instead of directly into the frame. This isn’t always feasible. If possible, disassemble the joint, drill a hole at the screw location, and insert a dowel plug, gluing it in place. Then, reassemble the joint with a screw and glue, as previously described. To conceal the screw head, you can either enlarge the hole for a dowel plug or slightly countersink the screw and fill the depression with wood filler.

Rebuilding: Disassembling and Doweling

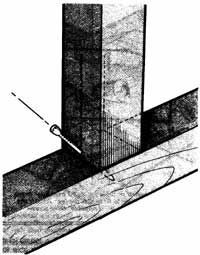

If a joint doesn’t come apart easily, it may be secured by nails or screws. These fasteners should be removed before attempting to disassemble the joint.

If a joint doesn’t come apart easily, it may be secured by nails or screws. These fasteners should be removed before attempting to disassemble the joint.Rebuilding a joint, or a series of joints, is not as difficult as it may seem, though it requires patience. Take your time to ensure all parts are properly aligned and fit tightly. To disassemble the joint, gently pull the pieces apart. If it resists, use a rubber or wooden mallet to tap the frame pieces apart, being cautious not to damage the wood.

Don't forget that the joint might have been put together with nails or screws in addition to the adhesive. If that's the case, it's important to remove the fasteners before breaking the adhesive. If the fasteners cannot be removed, break the adhesive bond and gently pry the joint apart. Avoid forcing the joint apart. If the nails or screws are too firmly embedded, attempting to force the joint could cause the wood to split or splinter. If prying could damage the wood, consider cutting through the joint with a hacksaw, using a thin blade that will go through metal without creating a wide cut.

Once the joint is disassembled, it needs a thorough cleaning. If the old adhesive is brittle or crumbling, use a knife or narrow chisel to scrape it off. If it's harder to remove, sandpaper, hot water, or a hot vinegar solution can help. It’s crucial to remove all dirt and old adhesive. Regardless of the method, take extra care not to damage the wood, as this could prevent the joint from fitting properly during reassembly.

Structural issues are most common in chairs and tables, and the joints typically used are mortise-and-tenon joints (a prong or tongue of wood that fits into a hole in the adjoining piece). Often, the tenon (the prong or tongue of wood) is worn or broken. If the damage is minimal, cleaning the joint thoroughly and reassembling it with epoxy — which serves both as a filler and a bonding agent — can restore it. After reassembly, be sure to wipe away any excess epoxy and clamp the joint until it is completely dry.

Let the piece of furniture sit out of use for at least a week to allow the glue to cure properly. If the tenon is severely damaged, or if the joint was sawed apart, you will need to rebuild the joint using hardwood dowels to replace the tenon. For most joints, two dowels are sufficient. The dowels should be about the same width as the tenon and roughly twice as long. Cut off the damaged tenon, remove any broken wood from the mortise, and fill the mortise with a wood plug. Glue the plug in place and trim it flush with the surface. Finally, use dowels to reassemble the parts.

To drill the holes for the dowels — both in the tenon base and the plugged mortise — use a doweling jig, which should be clamped to the edge of the wood and adjusted to center the dowel holes. While dowel center points can also be used, they are less accurate than a jig. Drill the holes about 1/4 inch deeper than the length of the dowels to allow for glue buildup under the dowels.

Use pliers to score the sides of the dowels and lightly round the ends with sandpaper or a file. This helps distribute the glue evenly and makes inserting the dowels smoother and more precise. Apply glue to the dowels and insert them into the holes on one side of the joint. Then, coat the edge of the wood with glue and slide the other piece of the joint onto the dowels. Tap the joint gently with a rubber or wooden mallet, remove any excess glue that oozes out, and clamp the joint tightly for about two days, allowing the glue to fully set.

Loose joints in wooden furniture can lead to long-term damage to the entire frame by putting extra stress on other joints. However, knowing how to fix or replace a damaged joint can help prevent the premature disposal of your furniture.

Publications International, Ltd.