Traveling sprinklers are remarkably efficient. John Slater / Getty Images

Traveling sprinklers are remarkably efficient. John Slater / Getty ImagesPicture watering your entire yard without the need to move the sprinkler every hour. What if the sprinkler moved on its own? That's exactly what traveling sprinklers do, all without relying on electrical or gasoline power.

This article will explore the mechanics behind tractor traveling sprinklers, a leading design in the market. It’s incredible how much these clever devices achieve using only water pressure.

Pressure, Torque, and Gears

A standard tractor traveling sprinkler

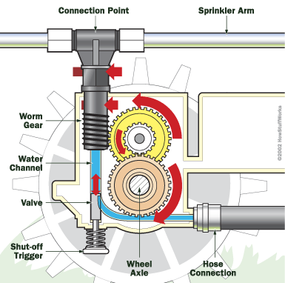

A standard tractor traveling sprinklerThe core concept behind a traveling sprinkler is to use water pressure to drive a basic transmission. Essentially, the water force from the hose activates a series of gears connected to an axle, causing the sprinkler’s wheels to rotate slowly.

This type of tractor traveling sprinkler contains just seven key components:

- A sprinkler arm assembly

- A worm gear

- A transmission

- Three wheels

- A plunger beneath the sprinkler

- A ramp

- A hose connector

Clockwise from top left: the hose connector, shut-off plunger, and gear shift

Clockwise from top left: the hose connector, shut-off plunger, and gear shiftWater entering your home from the water supply always comes with pressure, usually between 40 to 60 psi (pounds per square inch). When the faucet is turned on, the water pressure drives the water through the hose to the sprinkler. It then travels through a pipe in the sprinkler and exits through two attached sprinkler arms.

As the water flows out, it creates an equal and opposite force pushing back on the arms (this is the same principle used in rockets and jet engines). The ends of the arms are curved so the force pushes each arm at an angle. Since the arms are bent in opposite directions, the combined forces create torque – a rotational force. It’s similar to a merry-go-round with water-powered rockets on either side.

The arms are linked to a plastic worm gear inside the tractor’s body. As the arms spin, they rotate the worm gear, which engages a gear in the transmission. The transmission is a simple gear mechanism that transfers the rotational force from the worm gear to the drive axle, which turns the tractor’s rear wheels.

The basic function of a traveling sprinkler. The actual gear setup is slightly more intricate. The gear system in a tractor traveling sprinkler

The basic function of a traveling sprinkler. The actual gear setup is slightly more intricate. The gear system in a tractor traveling sprinkler The fundamental operation of a traveling sprinkler. The actual gear setup is a bit more intricate. The gear system in a tractor traveling sprinkler

The fundamental operation of a traveling sprinkler. The actual gear setup is a bit more intricate. The gear system in a tractor traveling sprinkler The fundamental operation of a traveling sprinkler. The actual gear setup is a bit more intricate. The gear system in a tractor traveling sprinkler

The fundamental operation of a traveling sprinkler. The actual gear setup is a bit more intricate. The gear system in a tractor traveling sprinklerIn a typical design, the transmission offers three settings (though some may feature more or fewer, and some designs might not offer different speed options). These include high and low speeds, as well as a neutral option for stationary watering. Changing the setting engages and disengages gears in the transmission. Completely disengaging the gear train from the drive axle places the sprinkler in neutral, while switching between gears alters the rotation speed of the axle (refer to How Gear Ratios Work for further details).

The gear drive system is similar to the gear mechanism in a car, but everything operates at a much slower pace. Most only travel at about 60 feet per hour! The rear wheels push the front wheel, guiding the tractor along the hose.

When the sprinkler reaches the end of its route, it activates its automatic shut-off. In its simplest form, the automatic shut-off trigger is a small ramp at the end of the tractor’s path. As the tractor sprinkler reaches the ramp, the front wheel climbs over it as if it were just another bump in the yard, but the back wheels go around it. The ramp activates a spring-loaded plunger at the bottom of the tractor, halting water flow to the sprinkler arms and stopping the tractor.

That's essentially the whole concept. It’s a straightforward conversion of water pressure into rotational force that moves the wheels.