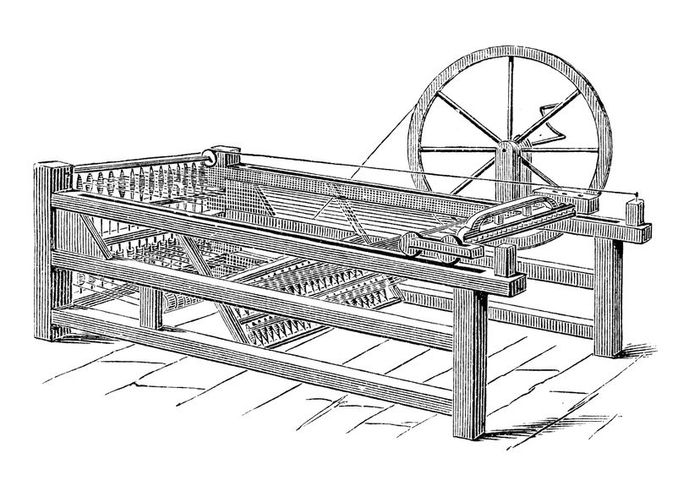

The spinning jenny's wheel enabled greater power output than manual spinning, revolutionizing textile production. ilbusca / Getty Images

The spinning jenny's wheel enabled greater power output than manual spinning, revolutionizing textile production. ilbusca / Getty ImagesDuring the Industrial Revolution, English inventor James Hargreaves introduced the spinning jenny, a groundbreaking innovation that moved textile production away from cottage industries and toward mechanized, centralized systems.

What Is a Spinning Jenny?

The spinning jenny, a groundbreaking invention from the late 18th century during the Industrial Revolution, transformed yarn production by enabling a single worker to spin several threads at the same time.

Some believe the term "spinning jenny" combines "jenny," a nickname for spinning wheels, with the popular name "Jenny" from that era.

An alternative theory proposes that "Jenny" might have been a slang term for "engine," though the true origin of the name remains unclear.

Who Invented the Spinning Jenny and How Did It Work?

James Hargreaves, an English carpenter, created the spinning jenny in 1765 and patented it in 1770. His invention aimed to overcome the inefficiencies of manual spinning, which was labor-intensive and slow. The spinning jenny automated the process, allowing multiple threads to be spun simultaneously.

The spinning jenny featured a frame with eight spindles mounted on a spindle roll. Each spindle was fitted with a roving, a loosely twisted bundle of fibers ready for spinning.

A large wheel, turned by hand, powered the spindles through a series of cogs and pulleys. As the spindles spun, the rovings were drawn out and twisted into yarn, dramatically increasing production compared to older spinning techniques.

Effects of the Spinning Jenny During the Industrial Revolution

Before this invention, spinning was largely carried out in small-scale cottage industries by skilled workers. The spinning jenny mechanized the process, paving the way for large textile factories and centralized production systems.

The spinning jenny also laid the groundwork for advancements like the spinning mule and Richard Arkwright's cotton factories. By boosting yarn output, it increased the demand for raw cotton, driving the textile industry's expansion and making innovations like the cotton gin more desirable.

The success of James Hargreaves' spinning machine laid the groundwork for future innovations in textile machinery, ultimately leading to the full mechanization of manufacturing processes.

Impact of the Spinning Jenny

The textile industry shifted from manual labor to machine-driven production. The spinning jenny enabled workers to produce more yarn with less effort, boosting output and lowering costs. This made textiles more affordable and widely available.

Despite its benefits, the spinning jenny had drawbacks. Skilled spinners and weavers faced job losses as the machine required little expertise to operate. Even unskilled workers, including women and children, could run the spinning wheels, reducing the need for trained artisans.

Spinning Jenny Legacy and Further Developments

Although revolutionary, the original spinning jenny had its drawbacks. It relied on a single wheel that needed manual operation. Later innovations, like steam power and Arkwright's water frame, overcame this by using water to automate the spinning process.

The spinning jenny was a pivotal moment in textile manufacturing history. It set the stage for advanced machines like the spinning mule and power loom, which further streamlined and automated textile production.