Dyson now provides various types of air treatment fans, including models that both cool and heat the air, along with fans that also serve as humidifiers.

Dyson now provides various types of air treatment fans, including models that both cool and heat the air, along with fans that also serve as humidifiers.In October 2009, James Dyson’s renowned consumer electronics company, famous for its vacuums, launched the Dyson Air Multiplier. This device stood out with a unique feature: it lacked visible blades. It appeared to be a sleek, circular tube mounted on a pedestal.

Since then, Dyson has broadened its range of air treatment products, all utilizing bladeless fan technology. These products now include air purifiers, some of which also function as humidifiers for dry environments, while others serve as both heaters and fans circulating air.

At first glance, these devices may seem like they wouldn't generate a warm or cool breeze. With no visible moving parts, how can they produce airflow? What’s the secret to how they push air without traditional fan blades?

The operation of these devices involves some key scientific principles, along with an electronic component. Although the tube itself is blade-free, the fan's pedestal houses a brushless electric motor that pulls air into the circular tube. The air travels through the tube until it reaches a slit, which initiates the airflow that produces the breeze you feel when standing in front of the fan.

Dyson claims that the breeze produced by these bladeless devices is more consistent and smoother compared to that of a typical fan with blades. Since there are no rotating blades, the airflow from these fans doesn't cause abrupt, gusty bursts of wind.

What’s the technology behind this innovation?

The Mechanics of the Air Multiplier

Although the Dyson Air Multiplier appears to be bladeless, there are blades concealed within the unit's base. Dyson

Although the Dyson Air Multiplier appears to be bladeless, there are blades concealed within the unit's base. DysonReferring to the Dyson Air Multiplier as a fan without blades might be slightly misleading. It does have blades, but they’re hidden inside the pedestal. A motor spins nine asymmetrically placed blades to draw air into the device. Dyson claims that the latest versions can push over 77 gallons of air per second to provide effective cooling airflow.

The airflow is directed through the rear of the device. But how does the fan manage to amplify the amount of air entering the pedestal?

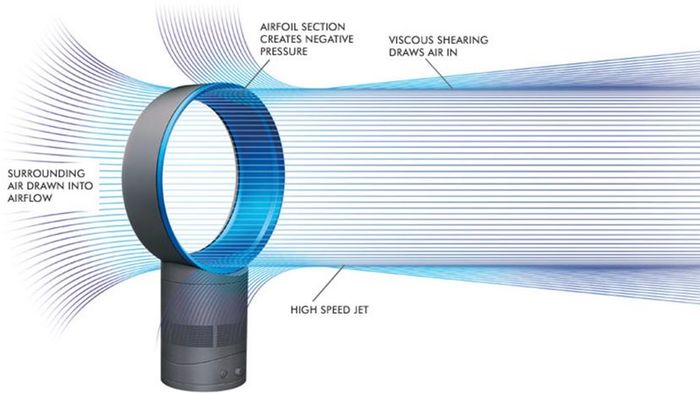

It’s all about physics. Although the atmosphere is gaseous, gases follow the principles of fluid dynamics. As air flows through the slits in the circular tube and exits the front of the fan, air behind the fan is also drawn into the tube. This process is known as inducement. The air pushed by the motor creates a vacuum that pulls more air in from behind the fan.

The air around the edges of the fan also begins to flow along with the breeze. This effect is known as entrainment. Thanks to both inducement and entrainment, Dyson asserts that its fans boost the airflow output by 15 times the amount drawn in by the pedestal's motor.

However, Dyson faced a challenge with its groundbreaking fan design. Next, you’ll learn why the company decided to alter the design of its Air Multiplier when creating a second version.

Multiplying Air, Reducing Noise

Dyson engineers dedicated significant effort to reduce the noise of the Air Multipliers. The second-generation model, pictured here, operates 75 percent quieter than the previous version. Dyson

Dyson engineers dedicated significant effort to reduce the noise of the Air Multipliers. The second-generation model, pictured here, operates 75 percent quieter than the previous version. DysonDespite its innovative design, the original Dyson Air Multiplier had one significant drawback: it wasn't particularly quiet. Dyson recognized this issue and set out to redesign the second generation of its fan.

This improvement required a substantial investment from the company. Dyson spent over $60 million on research and assigned 65 engineers to the task. Together, they developed 640 prototypes and filed hundreds of patents, continuously refining each design to better understand how air moves within their unique fan.

As you might expect, much of the noise stemmed from turbulence. The original Air Multiplier pulled air into its base, where it swirled around unpredictably, causing chaos and noise. To identify the source of this noise, researchers placed the fan in a soundproof chamber, where 10 microphones were used to capture every whir and hum.

Next, they created transparent prototypes and passed ultraviolet paint and smoke through the device. High-speed cameras then provided frame-by-frame playback, revealing exactly where the air was clumping together and generating disturbance.

To solve the turbulence issue, Dyson's engineers incorporated Helmholtz cavities into the fan's base. If you've ever held a seashell to your ear or blown across the top of a glass bottle, you've experienced the effect of these cavities, where sound bounces and travels across a hard surface.

Helmholtz cavities, by nature, generate noise. However, by understanding how these cavities function, it becomes possible to control the sound they produce. By incorporating Helmholtz cavities into the base of the Air Multiplier, engineers were able to increase air pressure, and these cavities ultimately acted as silencers.

Car manufacturers are well-versed in using Helmholtz cavities to reduce noise in exhaust systems. For the Air Multiplier, engineers specifically tuned these cavities to reduce sounds in the 1,000 Hertz range, frequencies that are particularly irritating to the human ear.

Their hard work (and substantial research funding) paid off. Dyson claims the second-generation Air Multiplier was 75 percent quieter than the first model. Additionally, with air flowing more smoothly and efficiently throughout the fan, the company was able to reduce the motor's power consumption by 40 percent.

For its remarkable reduction in noise, the second-generation Air Multiplier earned a Quiet Mark award from the Noise Abatement Society in 2014. This award is given to products that effectively reduce unnecessary noise pollution.

Beyond Cooling Air

The Dyson Pure Hot+Cool purifier employs the same Air Multiplier technology to trap ultrafine pollutants and circulate purified, heated air throughout the room.

The Dyson Pure Hot+Cool purifier employs the same Air Multiplier technology to trap ultrafine pollutants and circulate purified, heated air throughout the room.Dyson has significantly expanded the capabilities of the Air Multiplier beyond just blowing cool air. The Dyson Cool fan maintains the core Air Multiplier technology, but newer models now include HEPA filters that, according to the company, provide 50% cleaner air by capturing 99.95% of pollutants, including formaldehyde.

Customers can now choose from models that either humidify, purify, and cool a room or purify, heat, and cool a space. Many of these modern devices can be connected to your home Wi-Fi and are compatible with voice assistants.

This advanced technology doesn't come cheap, with prices starting around $400 for a fan with an air purifier. Fans with additional features can cost as much as $1,000.

There's no doubt that the Dyson Air Multiplier is a remarkable innovation. Its sleek design and cutting-edge technology sparked a lot of buzz when it first debuted. Perhaps in the future, we’ll see fans with no visible blades at all.