The Vienna Climactic Tunnel allows engineers to test objects in extreme temperatures. It is one of the few wind tunnels globally capable of testing full-sized rail cars.

Courtesy of RTA

The Vienna Climactic Tunnel allows engineers to test objects in extreme temperatures. It is one of the few wind tunnels globally capable of testing full-sized rail cars.

Courtesy of RTAEssential Takeaways

- Wind tunnels are pivotal for testing the aerodynamics of everything from airplanes and automobiles to industrial and consumer products, helping to improve safety, performance, and efficiency.

- These large, hollow structures simulate controlled wind conditions to observe how objects interact with airflow. By using sensors and visualization tools, engineers collect data on aerodynamic forces such as lift, drag, and turbulence.

- Progress in wind tunnel design, combined with advances in computational fluid dynamics, has played a key role in technological breakthroughs in fields like aviation, automotive engineering, and architecture, allowing engineers to craft safer and more efficient vehicles and structures.

Humankind has long admired the flight of birds. While we might skip the worm-eating part, their mastery of flight sparked humanity's desire to conquer the skies. Over time, people have made remarkable strides in this pursuit. However, the dream of 727s, missiles, space shuttles, high-speed race cars, speedboats, racing bicycles, and even certain types of computer chips may never have been achieved without the critical development of the wind tunnel.

Wind tunnels are essential tools used by engineers to examine the aerodynamics of various objects, such as jet wings and car windshields. Aerodynamics is the study of how air or gases flow around moving objects. By understanding the movement of air around (or through) these objects, manufacturers can create faster, safer, more reliable, and more efficient products across different industries.

Mother Earth's wind, ranging from gentle breezes to hurricane-force gusts, is notoriously unpredictable and thus unsuitable for aerodynamics testing. Wind tunnels, however, offer a controlled setting perfect for this type of experimentation.

A wind tunnel is essentially a hollow tube equipped with powerful fans at one end, creating a flow of air within the tunnel. Some tunnels are small, suitable for testing tiny objects, while others are enormous and used to test full-sized aircraft and automobiles. Though the test materials usually remain stationary, the rapid airflow inside the tunnel gives the illusion that the objects are moving.

Inside most wind tunnels, various sensors and instruments are used to collect precise data about how objects interact with the wind. Often, large windows are present, allowing scientists to visually observe the tests. This data helps engineers analyze key aerodynamic variables such as pressure, velocity, temperature, and density. They also measure lift, drag, shockwaves, and other conditions that impact vehicles like planes. Moreover, wind tunnels assist in understanding how wind affects stationary structures like buildings and bridges, helping improve their safety and durability.

In essence, many modern technological advancements owe a great deal to wind tunnels. Yet, it was the human aspiration for flight that initially inspired the development of these remarkable machines. Now, let's explore how wind tunnels came into existence and how they function—prepare for an exhilarating journey through the science of airflow that just might blow your mind.

Shaping the Future of Flight

The earliest airplane and glider designs were heavily inspired by birds, but wind tunnel experiments quickly demonstrated that many of these bird-like ideas were not as practical as hoped.

Stringer/Hulton Archive/Getty Images

The earliest airplane and glider designs were heavily inspired by birds, but wind tunnel experiments quickly demonstrated that many of these bird-like ideas were not as practical as hoped.

Stringer/Hulton Archive/Getty ImagesIn their quest to send humans soaring into the sky, early aviation pioneers looked to birds for guidance. Leonardo da Vinci, for example, designed an 'ornithopter' in 1485. Yet, despite their impressive flight abilities, birds proved not to be the best teachers when it came to understanding the mechanics of human flight. Many inventors built bird-inspired contraptions, only to see them fail miserably.

Realizing the need for a deeper understanding of how wings interacted with the wind, early aviation enthusiasts sought out hilltops, valleys, and caves that could provide powerful and somewhat predictable winds. However, natural winds proved too erratic, lacking the steady flow required for meaningful design feedback—only artificial winds could provide the consistency needed.

In 1746, Benjamin Robins, an English mathematician and scientist, introduced the concept of whirling arms. He attached a horizontal arm to a vertical pole and set it in motion, causing it to spin in a circle. At the end of the arm, he placed various objects and subjected them to the forces of his makeshift centrifuge. His experiments quickly revealed that the shape of objects had a significant impact on air resistance (known as drag), a key factor in aerodynamic design.

Other pioneers, including Sir George Cayley, soon developed spinning arms for testing. Cayley, in particular, focused on examining airfoil shapes, which resembled a cross-section of an airplane wing, to explore the concepts of drag and lift. Lift is a force that acts perpendicular to the direction an object moves.

However, the rotating arm had an unfortunate side effect—it disturbed the air as it spun, creating intense turbulence that affected all test results and observations. Nevertheless, this experiment led to a crucial realization: engineers discovered that rapidly moving an object through the air could generate lift. This meant that flapping wings were unnecessary for flight. Instead, humans needed sufficient power and the right wing design. To solve these problems, scientists needed more advanced investigative tools—wind tunnels provided the solution.

In the next section, you’ll learn how spinning arms evolved into wind tunnels—and how these tunnels became central to one of humanity’s greatest technological achievements.

The Whirling Winds of Change

The wind tunnel built by the Wright Brothers was pivotal in altering the trajectory of human technological advancement.

The wind tunnel built by the Wright Brothers was pivotal in altering the trajectory of human technological advancement.Due to the turbulence caused by whirling arms, which rendered many experiments unreliable, scientists were in need of smoother, artificial winds. Frank H. Wenham, an Englishman involved with the Aeronautical Society of Great Britain, persuaded the organization to help fund the creation of the first wind tunnel, which made its debut in 1871.

Wenham's wind tunnel measured 12 feet (3.7 meters) in length and 18 inches (45.7 centimeters) in width. It could generate winds of 40 miles per hour (64 kilometers per hour) thanks to a steam-powered fan at the tunnel's end. Within this tunnel, Wenham tested how different airfoil shapes responded to lift and drag forces. By adjusting the front edge (called the leading edge) of the airfoil up and down, thus changing the angle of attack, Wenham discovered that certain shapes provided better lift than previously expected. Suddenly, human-powered flight seemed far more achievable.

However, the rough design of Wenham's tunnel produced winds that were too inconsistent for reliable testing. A more refined tunnel was needed for systematic experiments and dependable results. In 1894, English inventor Horatio Philips replaced the fan system with a steam injection system, which produced a smoother and steadier airflow.

Meanwhile, in Ohio, across the Atlantic, the Wright brothers, Orville and Wilbur, were closely following advancements in aerodynamics and designing their own gliders. However, testing their models in the real world was proving to be a time-consuming process and lacked the precision necessary for improvements.

Recognizing the need for a wind tunnel, the Wright brothers went to work and built a model with a 16-inch (40.6-centimeter) test section. They tested approximately 200 different wing shapes by mounting airfoils onto two balances—one measuring drag and the other measuring lift. These balances translated the airfoil's performance into mechanical actions, which the brothers used to refine their calculations.

Through tireless effort, they found the ideal balance between drag and lift. They discovered that long, narrow wings produced significantly more lift than short, thick wings. In 1903, their persistent wind tunnel testing paid off, and the Wright brothers achieved the first manned, powered flight in Kill Devil Hills, North Carolina. A new era of technological breakthroughs had begun, largely thanks to the use of wind tunnels.

Next, you’ll learn precisely how wind tunnels perform their invisible magic, propelling humanity into a new era of technological progress.

Wind Tunnel Inner Workings

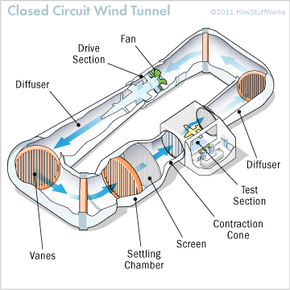

Here’s a helpful diagram to aid in visualizing the essential components of a wind tunnel.

Mytour

Here’s a helpful diagram to aid in visualizing the essential components of a wind tunnel.

MytourThe early wind tunnels were basic ducts with fans at one end. These tunnels created turbulent, inconsistent air, so engineers continuously refined the designs to improve airflow. Today’s wind tunnels provide far smoother airflow thanks to a core structure that includes five key sections: the settling chamber, contraction cone, test section, diffuser, and drive section.

As air enters the tunnel, it is initially a swirling, chaotic mass. The settling chamber performs exactly as its name suggests: it calms and straightens the air, often with the help of panels featuring honeycomb-shaped holes or mesh screens. The air is then forced through the contraction cone, a narrowed section that significantly boosts the velocity of the airflow.

Engineers position their scaled-down models in the test section, where sensors collect data and researchers make visual observations. From there, the air flows into the diffuser, which is shaped like a cone and gradually widens, slowing the airflow smoothly without disturbing the air in the test section.

The drive section contains the axial fan that generates high-speed airflow. This fan is always placed downstream of the test section, at the end of the tunnel, rather than at the entrance. This arrangement allows the fan to draw air into a smooth, steady stream, unlike a push system that would create more turbulent airflow.

Most wind tunnels are simply long, straight channels known as open-circuit (open-return) tunnels. However, some are designed as closed circuits, which are looped systems that recirculate the air along a continuous path, like a racetrack, using vanes and honeycomb panels to carefully manage and direct the airflow.

The tunnel’s walls are meticulously smooth, as any irregularities could create turbulence by acting as speed bumps. Most wind tunnels are compact enough to fit into university science labs, meaning that test objects often have to be scaled down to fit inside. These models might include miniature versions of entire airplanes, created with great precision (and cost), or they may represent just a single component, such as a part of an airplane wing or another product.

Engineers secure models in the test section using various techniques, often by fastening them with wires or metal rods placed behind the models to ensure they don't disrupt the airflow. Sensors may be attached to the models to capture data on wind speed, temperature, air pressure, and other important factors.

Keep reading to explore how wind tunnels assist scientists in solving more intricate aerodynamics challenges and how their discoveries drive technological breakthroughs.

Smoke on the Airstream

Smoke is used to visualize air movement, helping scientists observe how the air flows around the object being tested.

Bill Pugliano/News/Getty Images

Smoke is used to visualize air movement, helping scientists observe how the air flows around the object being tested.

Bill Pugliano/News/Getty ImagesLift and drag are just two components of the aerodynamic forces that are at work inside a wind tunnel. When testing aircraft, there are numerous other factors, such as pitch, yaw, roll, and more, that can influence the outcomes of the experiments.

Various factors influence testing, regardless of the test subject. For instance, the air quality inside the tunnel can fluctuate, significantly impacting the test results. Besides accurately measuring the shape and speed of the object (or the wind passing over the object), testers must also account for the viscosity (stickiness) and compressibility (bounce) of the air during their experiments.

Although you don't usually think of air as sticky, as it flows over an object, its molecules strike the surface and adhere to it for a brief moment. This forms a boundary layer of air adjacent to the object, influencing airflow in much the same way the object does. Factors like altitude, temperature, and other conditions can alter viscosity and compressibility, which in turn changes the properties of the boundary layer, drag, and the aerodynamics of the test object as a whole.

Determining how all these variables impact the test object requires a network of sensors and computers to record the data. Pitot tubes measure airflow velocity, while more advanced wind tunnels utilize laser anemometers that gauge wind speed by detecting airborne particles. Pressure probes track air pressure, and water vapor pressure sensors monitor humidity levels.

Beyond sensors, visual observations also play a vital role, but to make airflow visible, scientists use various flow visualization methods. They might fill the test section with colored smoke or a fine mist of liquid like water to track how air flows over the model. They may even apply thick, colored oils to the model's surface to observe how the wind moves the oil along.

High-speed video cameras can capture the movement of smoke or oils, allowing scientists to detect subtle details that aren't visible to the naked eye. In certain cases, lasers are employed to illuminate the mist or smoke and reveal the finer aspects of airflow.

Wind tunnels provide limitless possibilities for exploring countless ideas and innovations. Keep reading to uncover the remarkably creative wind tunnels that engineers design when they have the resources to transform a simple concept into a grand-scale technological marvel.

Wind Tunnels from A to Z

Supersonic and hypersonic tunnels operate without fans. Instead, they create these extreme air speeds through blasts of compressed air stored in pressurized tanks positioned before the test section, which is why they're also called blowdown tunnels. Similarly, hypersonic tunnels are sometimes referred to as shock tubes, named for the brief but intense blasts they generate. Both types demand immense power, making them more suitable for brief or intermittent testing.

Wind tunnels can also vary in their ability to adjust air pressure. Certain tunnels allow for the regulation of air pressure, making them useful for specialized tests. For instance, NASA can configure a tunnel to simulate the low-pressure environment found on Mars when testing space vehicles.

Wind tunnels can be classified based on their size. Some are compact, ideal for testing smaller models or parts of an object. On the other hand, there are full-scale tunnels large enough to accommodate entire vehicles for testing.

Some wind tunnels are simply enormous.

NASA's Ames Research Center, located near San Jose, California, is home to the world's largest wind tunnel. Standing at 180 feet (54.8 meters) tall and stretching over 1,400 feet (426.7 meters) in length, it features a test section that measures 80 feet (24 meters) in height and 120 feet (36.5 meters) in width, large enough to house a plane with a wingspan of 100 feet (30 meters). The tunnel is powered by six massive four-story fans, each driven by 22,500 horsepower motors, capable of generating winds up to 115 mph (185 kph).

The size of a wind tunnel isn't the only impressive factor. Stay tuned to discover just how cutting-edge some of these tunnels truly are.

Wind tunnels aren't just for experts. You can find plans online to build your own wind tunnel at home, or even purchase kits with all the essential components. There are various types of wind tunnels designed for different purposes. These tunnels are categorized based on their features, such as the wind speed they generate in the test section.

Subsonic tunnels are used for testing objects with airflow speeds under 250 mph (402 kph). Transonic tunnels operate within the 250 mph to 760 mph (1,223 kph) range.

Supersonic tunnels generate airflow exceeding the speed of sound (768 mph or 1,235.9 kph). Hypersonic tunnels create intense wind speeds from 3,800 mph to 11,400 mph (6,115.5 kph to 18,346.5 kph), and even beyond that.

Wicked Wind Tunnels

General Motors owns the largest wind tunnel in the world specifically designed for automotive testing. The fan boasts a diameter of 43 feet (13 meters).

Bill Pugliano/News/Getty Images

General Motors owns the largest wind tunnel in the world specifically designed for automotive testing. The fan boasts a diameter of 43 feet (13 meters).

Bill Pugliano/News/Getty ImagesTo test a wide range of aerodynamic and environmental factors at once, engineers rely on wind tunnels that can accommodate multiple testing variables. One such tunnel is the Vienna Large Climatic Wind Tunnel, primarily used for automobile and rail vehicle testing. The test section stretches 328 feet (100 meters) long, with wind speeds reaching up to 186 mph (299 kph).

This tunnel allows engineers to adjust humidity levels from 10 to 98 percent, while temperatures can range from a frigid -49°F to a scorching 140°F (-45 to 60°C). True to its name, the Vienna Climatic Tunnel also features capabilities for rain, snow, and ice, as well as solar exposure simulations.

The ability to test icing conditions has been a critical aspect of wind tunnels for years, as ice accumulation on aircraft surfaces can be catastrophic, even leading to crashes. Icing tunnels use refrigeration systems to cool the air and spray fine water droplets into the airflow, forming a layer of ice on test models. Engineers then experiment with solutions to prevent ice buildup, such as installing heating systems that warm the surfaces of the plane.

Wind tunnels come in various designs tailored for specific purposes. Some models forgo poles or wires to secure test objects, instead using strong magnets to suspend metallic models in the test area. Others are equipped with remote control systems that allow scientists to 'fly' model planes within the wind tunnel.

The University of Texas at Arlington is home to the Aerodynamics Research Center, which houses an arc jet tunnel capable of generating supersonic jets of extremely hot gas, reaching temperatures as high as 8,540 degrees Fahrenheit (4,727 Celsius). Such intense heat is crucial for NASA, as it allows for testing spacecraft in conditions simulating the extreme heat experienced during re-entry into Earth's atmosphere.

Some wind tunnels opt to replace air with water. Due to its higher density and better visibility compared to air, water helps scientists observe flow patterns around submarines, ship hulls, and more clearly view shockwaves generated by fast-moving aircraft or missiles.

But why are scientists generating all these varying air currents? It's not just for their own enjoyment – on the next page, you'll discover the many practical uses of wind tunnels that extend far beyond aviation.

Vertical wind tunnels (VWTs) show that wind tunnels aren't limited to scientific purposes. VWTs enable people to experience indoor skydiving (known as bodyflying), providing a fun and safe way for both beginners and experienced skydivers to practice the sport.

Wind Tunnels Prove Their Worth

Indoor vertical wind tunnels, like the one in China, provide a platform for skydivers to practice their skills without jumping out of an aircraft.

Getty Images News/Getty Images

Indoor vertical wind tunnels, like the one in China, provide a platform for skydivers to practice their skills without jumping out of an aircraft.

Getty Images News/Getty ImagesEngineers and manufacturers utilize wind tunnels to enhance not just airplanes and spacecraft, but a wide range of industrial and consumer products. The automotive industry, in particular, makes extensive use of wind tunnels for product development.

General Motors operates the largest wind tunnel dedicated to studying car aerodynamics. Since its establishment over thirty years ago, the laboratory's engineers have successfully reduced the drag coefficient of their vehicles by about 25%. This significant improvement leads to a boost in fuel efficiency of two to three miles per gallon.

Race-car manufacturers turn to wind tunnels to refine vehicle aerodynamics, focusing on speed and efficiency to gain a competitive advantage. AeroDyn Wind Tunnel in North Carolina, for instance, specializes in testing full-size NASCAR stock cars and other racing vehicles. Windshear, another North Carolina-based company, operates a cutting-edge closed-circuit tunnel with a built-in rolling road, essentially a massive treadmill for cars.

Engineers in electronics use small-scale wind tunnels to study how airflow affects heat buildup in electronic components. This helps in designing cooler computer chips and motherboards with longer lifespans. Additionally, utilities managers employ wind tunnels to test wind turbines for electricity generation, enhancing their efficiency, durability, and resistance to powerful gusts. Wind tunnels also aid in optimizing wind farm layouts and turbine spacing to increase efficiency while minimizing turbulence that wastes energy.

Building wind tunnels and test models can be quite costly. As a result, many organizations are moving away from maintaining their wind tunnels and opting for computer modeling (also known as computational fluid dynamics), which is increasingly used in place of physical models and tunnels. Additionally, computers allow engineers to manipulate a virtually endless range of variables in the model and test section, eliminating the need for time-consuming and expensive manual labor. In some cases, physical wind tunnels are only used to verify the outcomes of computer simulations.

Engineers involved in construction use computer modeling for wind engineering tests, which aids in the design and construction of skyscrapers, bridges, and other structures. They examine the interaction between building shapes, materials, and wind to enhance safety and durability.

Despite the rise of new virtual technologies, wind tunnels remain in active use worldwide, helping scientists design safer and more efficient products and vehicles across various industries. Even if physical wind tunnels are eventually replaced by advanced virtual technologies, these engineering feats will always hold a significant place in the history of human innovation.