An inside glimpse into a standard automated car wash.

An inside glimpse into a standard automated car wash.Let’s be honest—most of us own a car or truck and love driving it, particularly when it’s spotless and gleaming. This is why car washes have stayed in demand since 1914, when two Detroit entrepreneurs launched the first one, the Automated Laundry. While many people still wash their vehicles at home, the ease and affordability of automated car washes are tough to resist.

There are five main types of car washes:

- Self-service - These setups usually feature an open bay where the car is parked. Equipped with a pressure sprayer and occasionally a foaming brush, they connect to a central pump. A coin-operated dial lets you choose options like "soap," "rinse," or "wax." A timer cuts off the water after a set period, requiring more coins to continue.

- Exterior rollover - Increasingly popular, these automated systems have you drive into a bay. Once positioned, a signal tells you to stop, and the equipment moves over your car on a track, performing tasks like soaping or rinsing with each pass. Often found at gas stations, they’re sometimes discounted with a fuel purchase.

- Exterior only - Common in the northeastern U.S. but available worldwide, this system involves driving into a long, tunnel-like bay. The driver’s side front tire rests on a conveyor belt, and the car is put in neutral. The belt guides it through the bay, where various equipment performs specific tasks.

- Full service - Similar to the exterior-only system but enhanced, this option uses the same conveyor belt setup. Attendants manually clean the interior and may offer additional exterior services like hand-drying and wheel-cleaning.

- Detail shop - These shops may hand wash or use automated systems. Attendants thoroughly clean, polish, and wax the car, often using a buffer to remove wax and add shine. They can also address dull paint, minor scratches, steam clean interiors, brighten chrome, remove tar, and more.

This article delves into the conveyor-driven mechanisms found in exterior-only and full-service car washes. Discover each stage of the process and the machinery behind it. Ensure your windows are shut and your antenna is retracted as we take you through the tunnel experience.

Drive In

The system’s correlator consists of a series of extended rollers.

The system’s correlator consists of a series of extended rollers.Car washes typically operate as either touchless or cloth friction systems. A touchless car wash uses high-pressure water jets and potent detergents to clean the car, with only the water and cleaning agents making physical contact.

Cloth friction systems employ soft cloth materials that move across the car’s surface. While this article focuses on cloth friction technology, many components are shared with touchless car washes.

The process begins by positioning the car on the conveyor track. At the conveyor’s start is a correlator, a set of wheels or rollers designed to align the car’s wheel with the track by allowing it to slide sideways.

The car is switched off and set to neutral. Most conveyor systems feature small rollers that rise behind the wheel once it’s on the track. These rollers propel the wheel forward, guiding the car through the tunnel, the term for the elongated bay used in exterior-only and full-service setups. There are two primary conveyor system types:

- Front-wheel pull (FWP) - Engages the front left wheel

- Rear-wheel push (RWP) - Engages the rear left wheel

This car wash employs RWP to move the car along the conveyor.

This car wash employs RWP to move the car along the conveyor.As the car enters the tunnel, it crosses an infrared beam between two sensors, known as eyes.

One sensor emits infrared light, which is detected by the sensor on the opposite side.

One sensor emits infrared light, which is detected by the sensor on the opposite side.When the beam is blocked, the sensors send a signal to the digital control system (DCS), the computer managing the car wash’s automation. By calculating the duration of the interruption, the DCS gauges the vehicle’s length and adapts the system settings accordingly.

Soap Up

This image shows the tire applicators, the mitter curtain, and a section of the pre-soak arch.

This image shows the tire applicators, the mitter curtain, and a section of the pre-soak arch.Right after the sensors, most car washes feature a pre-soak arch. This structure is equipped with multiple small nozzles that spray a specialized solution across the car. This solution serves two purposes:

- Prepares the car’s surface by wetting it before detergent application

- Includes chemicals that start breaking down dirt and grime

Many car washes also have tire applicators, nozzles positioned near the ground. These spray a solution tailored to remove brake dust and restore the black rubber shine of the tire.

In this setup, the car then moves through a mitter curtain. This consists of long, soft cloth strips hanging from a frame at the tunnel’s top. The frame is attached to a motorized shaft, which moves it in a circular motion, causing the cloth strips to scrub the car’s horizontal surfaces.

The mitter curtain effectively cleans the hood, roof, and trunk by sweeping back and forth across these areas.

The mitter curtain effectively cleans the hood, roof, and trunk by sweeping back and forth across these areas.Next in the car wash process is the foam applicator. This device sprays a detergent that transforms into a thick, deep-cleaning foam upon contact with the car. The nozzles on the foam applicator, like most spray systems in car washes, can be adjusted to alter the spray angle and opening size. The foam is produced by blending a chemical cleaner (which varies by car wash) with water and air. Separate controls allow precise adjustments to the mixture. Often, the chemical includes a coloring agent to make the foam more visually appealing and noticeable.

Here, you can observe the foam generated by the detergent from the foam applicator.

Here, you can observe the foam generated by the detergent from the foam applicator.Once the car is coated with foam, we proceed to the scrubbers.

Scrub

Most car washes are equipped with several pairs of scrubbers.

Most car washes are equipped with several pairs of scrubbers.Scrubbers are tall vertical cylinders covered with hundreds of small cloth strips. These cylinders rotate quickly, ranging from 100 to 500 rpm, causing the cloth strips to extend outward. Despite their softness, the strips can feel like a whip if they hit you. Powered by hydraulic motors, scrubbers are positioned on each side of the car, sometimes in multiples. As the car moves through, the cloth strips clean its vertical surfaces.

Some car washes also feature wrap-around washers. These are scrubbers mounted on short arms that can reach the front and rear of the vehicle, cleaning those areas too. Like most car wash machinery, they are powered by a combination of electric motors and hydraulics, often connected to a central hydraulic power unit.

Wrap-around washers ensure the front and rear of the car are thoroughly cleaned.

Wrap-around washers ensure the front and rear of the car are thoroughly cleaned.The scrubbers’ cloth is exceptionally soft and is cleaned regularly to prevent any debris from scratching the cars. They are replaced when they become too worn or dirty to function effectively.

The scrubbers effectively remove dirt that has been loosened by the foam and pre-soak.

The scrubbers effectively remove dirt that has been loosened by the foam and pre-soak.Beyond the mitter curtain and scrubbers, many car washes also include a high-pressure washer.

Blast

The water jet nozzles resemble a pinwheel in design.

The water jet nozzles resemble a pinwheel in design.The high-pressure washer consists of rotating water jets that direct powerful streams of water onto the car. Each water jet features nozzles arranged like a pinwheel, angled slightly outward from the center.

The force of the water propels the jets into rapid spinning, creating a circular motion as the water hits the car. This combination of high-pressure streams and circular movement delivers a thorough scrubbing action. Some systems operate at up to 1,000 psi, powerful enough to knock a person off their feet!

The high-pressure water jets effectively strip away most of the detergent and dirt from the car.

The high-pressure water jets effectively strip away most of the detergent and dirt from the car.High-pressure systems consume a significant amount of water—approximately 300 to 400 gallons (1,100 to 1,500 liters) per car. To supply this volume quickly, car washes typically have a dedicated pressure tank nearby. Most systems recapture and recycle nearly all the water back into the pressure tank after each use.

The pressure tank designed for high-pressure washers

The pressure tank designed for high-pressure washersMany car washes, especially in regions with heavy snow during winter, feature an undercarriage wash applicator. Positioned at ground level, this system uses upward-facing nozzles to remove dirt, mud, and salt from the car’s underside.

Rinse

The rinse arch effectively eliminates nearly all remaining residue from the cleaning process.

The rinse arch effectively eliminates nearly all remaining residue from the cleaning process.Next, the car passes through a rinse arch, which consists of nozzles arranged in an arch shape. These nozzles spray clean water to remove any leftover residue after the high-pressure washer, scrubbers, and mitter curtain have completed their tasks.

A typical car wash includes multiple rinse arches, usually positioned after each major cleaning station. A standard setup might feature the following stations:

- Pre-soak

- Mitter curtain

- Rinse arch

- Foam applicator

- Scrubbers

- High-pressure washer

- Undercarriage wash applicator

- Rinse arch

- Wax applicator

- Mitter curtain

- Scrubbers

- Rinse arch

- Dryer

As shown in the example above, there are three rinse arches, along with two mitter curtains and two sets of scrubbers, which is common in many car washes. Some facilities may even include more of each type of station.

Many car washes feature two or more mitter curtains positioned along the tunnel.

Many car washes feature two or more mitter curtains positioned along the tunnel.The final rinse arch in the tunnel, known as the final rinse, always uses clean, non-recycled water to ensure no residue remains on the car’s surface.

Passing through the final rinse

Passing through the final rinseMost car washes also offer some form of protectant that can be applied to the car.

Wax

This wax arch features a triple-foam applicator, with each wax protectant represented by a distinct foam color.

This wax arch features a triple-foam applicator, with each wax protectant represented by a distinct foam color.A common element in car washes is the wax arch. The wax used here, which creates a water-resistant layer, differs significantly from hand-applied wax. It’s designed to work on glass, chrome, rubber, and painted surfaces, leaving a clear, thin film without the need for polishing. However, it doesn’t offer the same level of protection or scratch coverage as traditional wax.

The wax arch employs one of two methods to apply wax. The first uses foam applicators, often a triple-foam applicator, to apply a foam wax.

The wax foam is applied in a thick layer across the car.

The wax foam is applied in a thick layer across the car.The second method uses nozzles, similar to those in a rinse arch, to apply a liquid wax. After this, the car typically passes through a rinse arch. However, when foam wax is used, the car usually goes through additional scrubbers and a mitter curtain before the rinse arch.

Dry

This dryer arch features the silencer and nozzles visible on the left side.

This dryer arch features the silencer and nozzles visible on the left side.Once the car is fully washed, the final automated step is the dryer. Similar to a massive hair dryer, it heats large volumes of air and expels it through nozzles, quickly drying the car’s surface.

The dryer includes a large, flat, circular section before the nozzle opening, known as the silencer. Like a muffler or a gun silencer, it reduces the noise generated by the air being forced through the system.

In a full-service car wash, the dryer doesn’t fully dry the car, as attendants use towels to finish the job after it exits the tunnel.

In a full-service car wash, the dryer doesn’t fully dry the car, as attendants use towels to finish the job after it exits the tunnel.Some car washes use a special chemical after the final rinse, just before the dryer, to accelerate the drying process. The dryer’s temperature and intensity can be adjusted. Full-service car washes typically set the dryer lower than exterior-only washes, as attendants manually dry the car with towels to ensure no water remains.

Touch Up

The end of the line

The end of the lineAs the car exits the tunnel, it is guided off the conveyor track.

In an exterior-only system, you typically stay in the car. Once it exits the tunnel, you shift to park, start the engine, and drive away. In a full-service car wash, an attendant takes the car to the finishing station. There, they clean the interior, remove trash, vacuum, wipe the windows, and tidy the dashboard and doors. They may also add air freshener, hand-dry the exterior, and clean or polish the wheels and chrome, depending on the service package.

Attendants at Bunkey's Car Wash manually dry a car.

Attendants at Bunkey's Car Wash manually dry a car.The vacuum system at a car wash differs significantly from a standard home vacuum. It typically features a large central unit with multiple hoses, either suspended overhead or buried underground, leading to each vacuuming station.

This vacuum stands about 6 feet (1.8 m) tall and measures over 2 feet (0.6 m) in diameter.

This vacuum stands about 6 feet (1.8 m) tall and measures over 2 feet (0.6 m) in diameter.The vacuum’s air pump is extremely powerful, designed to support all the hoses and cover the distances required for each station.

The Controls

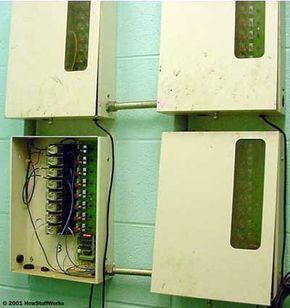

These boxes house the fuses for every station in the car wash.

These boxes house the fuses for every station in the car wash.All equipment in an automated car wash demands a robust power supply. Each station operates on its own fuse-protected circuit, and most car washes are built to keep running even if one station fails entirely.

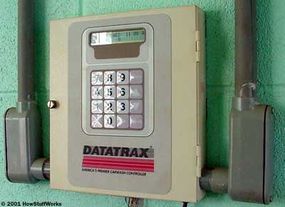

The digital control system (DCS) serves as the car wash’s central intelligence.

The digital control system

The digital control systemFrom the instant the eye signals the DCS that a car has entered, the DCS manages every detail of the car wash. It tracks the car’s location at all times and activates the necessary stations as required.

The Operation

A standard car wash uses less than half the water you’d typically use washing your car at home.

A standard car wash uses less than half the water you’d typically use washing your car at home.Running a car wash is a highly competitive and often stressful venture. With low revenue per car, high volume is essential for profitability. The weather plays a significant role—when it’s raining, customers stay away. Even forecasts of bad weather can deter people from washing their cars, as they assume the effort will be wasted.

Interestingly, most car washes use far less water than a home wash. For instance, washing a car at home typically consumes 80 to 140 gallons (304 to 532 liters), while a car wash (without high-pressure systems) averages under 45 gallons (171 liters) per car. Additionally, home washing sends chemicals and detergents into the sewer, whereas car washes must follow strict waste disposal regulations, making them more environmentally friendly.

This pit collects runoff water from the cars and recycles it for reuse.

This pit collects runoff water from the cars and recycles it for reuse.Many car washes recycle water to reduce consumption. This recycled water is typically used for initial rinses and mixing detergents, and sometimes in the high-pressure washer. However, it is never used for the final rinse.