Thunder Bay, a massive 2-million-gallon (7.6-million-liter) wave pool located at Wet 'n Wild Emerald Pointe in Greensboro, NC.

Thunder Bay, a massive 2-million-gallon (7.6-million-liter) wave pool located at Wet 'n Wild Emerald Pointe in Greensboro, NC.Modern society is brimming with man-made imitations of the natural world. Homes are adorned with synthetic Christmas trees, individuals wear faux hair, sports are played on artificial turf, and zoo enclosures are designed with fabricated rocks. Researchers have even engineered artificial hearts!

Among humanity's most peculiar recreations of nature is the artificial beach, commonly referred to as the wave pool. These beloved water park features offer a sanitized, controlled version of the untamed, natural waves found in the ocean. In wave pools, the water is treated with chlorine, the shoreline is made of concrete, and the waves are generated predictably, arriving at regular intervals.

In this article, we’ll explore the inner workings of Thunder Bay, the star attraction at Wet 'n Wild Emerald Pointe in Greensboro, NC. As we’ll discover, maintaining continuous waves throughout the day requires advanced, high-powered machinery. However, the fundamental concept behind it is surprisingly straightforward.

Creating Waves

The wave generator at Emerald Pointe's Splash Island utilizes compressed air to generate soft, rolling waves.

The wave generator at Emerald Pointe's Splash Island utilizes compressed air to generate soft, rolling waves.In the ocean, the majority of waves are formed by wind. As air moves across the water's surface, it compresses certain water molecules, creating a rise in the water level—a disturbance on the ocean's surface. This disturbance propagates as neighboring molecules push against each other, transferring the energy across the water. While the wave moves forward, the water molecules themselves remain relatively stationary.

There are several methods to mimic this natural wave phenomenon. All that's required is a body of water and a mechanism to create a regular disturbance. Options include a powerful burst of air across the surface, a rotating paddle wheel (similar to those on steamboats), or an oscillating plunger. Essentially, applying force to the water at one point causes the energy to radiate outward, much like the ripples formed when a stone is dropped into a pond.

Emerald Pointe boasts a wave pool of this kind at Splash Island, a designated swimming area for younger children. In this pool, gentle waves originate from the deeper end, near a volcano structure, and lap onto a small, sandy beach.

Let’s examine the equipment responsible for creating this effect.

Artificial Waves

The mechanism behind the ripple effect in Emerald Pointe’s wave pool is straightforward. Beneath the pool, in a pump room, a high-speed fan forces air through a broad metal pipe, which connects to an exhaust port at the volcano’s base. Within this pipe lies a butterfly valve, a disc with a rotating metal rod. When the rod turns one way, the disc lies horizontally, blocking airflow. When turned the opposite way, the disc shifts vertically, allowing air to pass through.

A hydraulic piston rotates the rod at regular intervals, releasing brief bursts of pressurized air to the exhaust port. These bursts of air push against the water at the volcano’s base, creating the gentle ripples.

Generating small waves is relatively simple with this system, but producing large, surfable waves is far more challenging. It would require an extremely powerful air blast or a massive, robust plunger. Such mechanisms would likely be inefficient, bulky, and hazardous, making them unsuitable for water park attractions. Instead, water parks rely on water-pumping wave systems. In the following sections, we’ll explore how these wave pools operate.

Simply Add Water

In the previous section, we explored a very basic wave pool design. In this setup, brief bursts of pressurized air exert force on a mostly still body of water, generating small waves that spread across the water's surface.

A more advanced wave pool system operates differently. Rather than using air or paddles to push the water, the wave machine releases a massive volume of water into the pool's deep end. This surge of water moves toward the beach, and the water level in the pool eventually stabilizes. Because water is dense and heavy, it exerts significant force to reach equilibrium. Increasing the volume of water dumped into the pool results in larger and more powerful waves.

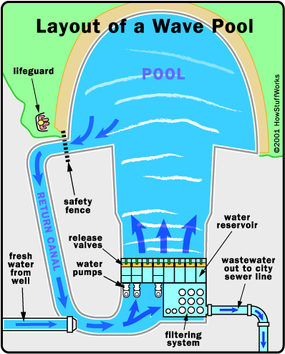

This process involves a range of powerful equipment, but the underlying concept is straightforward. The wave pool consists of five key components:

- A water-pumping system

- A water-collection reservoir

- A series of release valves at the bottom of the reservoir

- A large, sloped swimming pool

- A return canal, connecting the beach area to the pumping system

A Massive, Ultra-Clean Toilet

Robert Bochenski, the maintenance manager at Emerald Pointe, likens the "Thunder Bay" wave pool to a colossal toilet. The pump system pulls water from the return canal into the collection reservoir, similar to how a toilet draws water from its supply line into the tank. Once the reservoir reaches the required water level, the system opens the release valves at its base. This action mimics flushing a toilet, releasing all the stored water into the pool to generate waves.

In this setup, the water is in constant circulation. It flows from the pool's deep end into the canal, travels to the pumping system, and then returns to the deep end. The return canal is securely fenced to ensure swimmers are never near the pumping mechanism.

There are numerous ways to design the wave-generating system in this configuration. In the next section, we’ll explore the specific machinery used in Emerald Pointe’s Thunder Bay.

On a busy day, thousands of visitors will swim in the Thunder Bay wave pool, and even the cleanest individuals leave behind traces of dirt and oil. To ensure the water remains sanitary, Emerald Pointe operates a filtering system around the clock.

The Thunder Bay wave pool utilizes six large filters, positioned just behind the wave generator. A powerful pump draws water from the canal, directs it through the filtration system, and releases clean water back into the pool. The collected wastewater is then pumped to the city’s sewer line, located nearly a mile away.

Release the Power

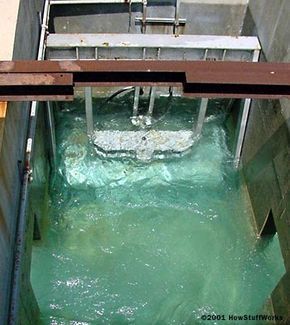

One of the release valves at Thunder Bay.

One of the release valves at Thunder Bay.Thunder Bay measures 84 feet (26 m) in width at its deep end and stretches over 400 feet (122 m) in length. The pool contains approximately 2 million gallons (7.6 million liters) of water, with each wave consisting of 90,000 gallons (341,000 liters). Generating a wave of this magnitude and ensuring it travels across the entire pool requires substantial, heavy-duty equipment.

The wave generator is powered by a 100-horsepower pump, a 200-horsepower pump, and a 300-horsepower pump. Each pump features a motor at the top, which rotates a long drive shaft. This shaft extends downward through a pipe to a propeller submerged 13 feet (4 m) underwater. As the drive shaft spins, it turns the propeller, pushing water upward through the pipe, similar to how a fan propels air forward.

At the base of the pump, the pipe curves horizontally for 6 feet (1.8 m), then ascends another 10 feet (3 m) before emptying into the water reservoir. In total, the pumps move water across a vertical distance of 29 feet (9 m). Operating at their standard speed, the pumps can move approximately 40,000 gallons (150,000 liters) of water per minute.

The water reservoir is divided into eight interconnected chambers, each equipped with its own release valve. The release valve consists of three main components:

- The valve seat - The opening that directs water down into the pool

- The valve plate - A large metal piece that fits tightly over the valve seat

- Metal struts that pivot on a fixed steel beam, connected to the reservoir walls on one end and the valve plate on the other

- The hydraulic-cylinder piston, linked to a metal beam between the two struts

Since the metal struts pivot freely on the stationary steel beam, the valve plate can swing back and forth. Due to its weight, the plate naturally covers the valve seat, sealing the reservoir and preventing water from escaping. (A rubber gasket around the valve seat ensures minimal leakage.)

When pressurized oil is sent to the hydraulic cylinder, it forcefully moves the piston. This action pushes the metal struts outward, lifting the valve plate and unsealing the reservoir. The water then flows into a curved passageway beneath the reservoir, leading into the pool. As it enters, the water is directed over a concrete reef, which focuses the flow, creating a sizable, surfable wave.

While the water pumps handle the bulk of the work in generating a wave, the hydraulic system is the key component that initiates the process. In the next section, we’ll explore the simple yet ingenious mechanism that controls this system.

A wave pool, like any swimming pool, continuously loses water. Some evaporates into the air, some is removed during filtration, and a significant amount is carried away on swimmers' bodies and bathing suits.

To maintain the water level in Thunder Bay, Emerald Pointe constantly replenishes it with fresh water. While the park is connected to the city water supply, most of the water comes from several underground wells. These wells pump water into the wave-pool canal and other feeder pools throughout the park. Although installing the wells required a substantial upfront investment, it significantly reduced long-term water expenses.

Oil and Water

The directional control valve that manages the release gates at Thunder Bay

The directional control valve that manages the release gates at Thunder BayIn the previous section, we learned that the wave generator's valves are activated by hydraulic pistons. Like most hydraulic machines, these pistons are powered by a basic hydraulic pump. The pump maintains a continuous flow of pressurized oil through the system. Emerald Pointe uses vegetable oil instead of standard machine oil to minimize risks, as there is a possibility of oil leaking into the wave pool.

In the wave generator, the flow of oil is regulated by a directional control valve. This valve is connected to several hoses, which lead to:

- The hydraulic pump

- A collection tank that returns oil to the pump

- The cylinder pistons

If you were to open up one of the piston cylinders, you would find something like this:

You’ll notice that the piston rod extending outside the cylinder is driven by a piston head inside the cylinder. Fluid is present on both sides of this piston head, supplied by two separate hoses. If the pressure is higher on the blue side, the piston moves to the left, and if it’s greater on the orange side, the piston moves to the right. To reverse the direction of movement, you stop pumping oil to one side and start pumping it to the other. This type of piston cylinder is often referred to as a hydraulic ram.

The directional control valve manages the flow of oil to these rams. It features a small spool that shifts back and forth, closing some inlet and outlet ports while opening others.

When the spool is positioned to the left, high-pressure oil flows to the left side of the cylinder, pushing the piston outward. When the spool is moved to the right, it forces the piston back in. As high-pressure oil acts on one side, low-pressure oil on the opposite side is pushed back into the oil tank.

The spool is shifted back and forth by a basic solenoid (an electromagnetic switch operated by an electric current). The solenoid is regulated by an electrical timer. Every two minutes, the timer triggers the solenoid, causing it to extend the pistons for a few seconds before retracting them. This action opens all the release valves, generating a wave.

One of the most remarkable aspects of this control system, and the wave generator as a whole, is its incredible durability. Throughout the summer, the Emerald Pointe team starts the waves at dawn and keeps the system running until the park closes in the evening. That’s one demanding schedule!