Implosive demolition is a secure method for dismantling large buildings. BryanLever / Getty Images

Implosive demolition is a secure method for dismantling large buildings. BryanLever / Getty ImagesMain Insights

- Imploding buildings involves precise planning with explosives to make the structure fall within its own base, reducing harm to the surrounding environment.

- Essential steps include weakening the building's framework, strategically placing explosives, and establishing a safety zone to safeguard onlookers and adjacent properties.

- Although implosions involve destruction, they are executed with extreme precision and safety measures.

A stone wall can be torn down with a sledgehammer, and a five-story building can be flattened using excavators and wrecking balls. However, when dealing with a massive structure like a 20-story skyscraper, more powerful methods are required. Explosive demolition is the go-to approach for safely and effectively dismantling larger buildings. If a structure is surrounded by other buildings, it might need to be "imploded", meaning it collapses inward into its own footprint.

This article explores how demolition teams meticulously plan and carry out these dramatic implosions. While the explosions and dust clouds may appear chaotic, a building implosion is actually a highly precise and carefully orchestrated engineering achievement.

The Larger the Structure, the Greater the Challenge

The fundamental principle behind explosive demolition is straightforward: Removing the support structure at a specific point causes the upper section of the building to collapse onto the lower section. If the upper part is sufficiently heavy, the impact will cause significant damage. Explosives act as the catalyst, but it's gravity that ultimately brings the building down.

The Reading Grain Facility in Philadelphia, Pa., was demolished by Controlled Demolition Group, Ltd. during the winter of 1999.

Photo courtesy ImplosionWorld.com

The Reading Grain Facility in Philadelphia, Pa., was demolished by Controlled Demolition Group, Ltd. during the winter of 1999.

Photo courtesy ImplosionWorld.comDemolition experts strategically place explosives on multiple floors of a building to ensure it collapses inward at various points. When executed correctly, the combined force of the explosives and falling debris causes the entire structure to crumble, leaving cleanup crews with nothing but a heap of rubble.

To safely demolish a building, experts meticulously plan every aspect of the implosion. They start by reviewing architectural blueprints, if available, to understand the building's construction. Next, they conduct multiple inspections, noting the support structures on each floor. With this data, they devise a detailed strategy, drawing on past experiences to determine the type of explosives, their placement, and the timing of detonations. In some cases, they create 3-D computer models to simulate the implosion beforehand.

The primary challenge in demolishing a building is controlling its direction of collapse. Ideally, the structure is toppled to one side, such as into a parking lot or open space. This method is the simplest and safest. To achieve this, explosives are detonated on the side where the building should fall, similar to cutting a tree in a specific direction. Steel cables may also be attached to support columns to guide the collapse.

When a building is surrounded by other structures that must remain intact, a true implosion is necessary. This involves collapsing the building straight down into its own footprint. This highly skilled task is attempted by only a few demolition companies worldwide.

Each demolition project is approached uniquely, but the general strategy involves treating the building as a series of interconnected towers. Explosives are set so that each "tower" collapses toward the center, similar to toppling a single structure sideways. When detonated in sequence, the falling towers collide, concentrating the rubble at the building's core. Alternatively, central columns can be detonated first, causing the sides to collapse inward.

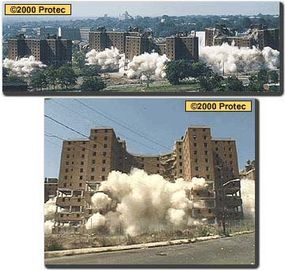

The Hayes Homes in Newark, N.J., a 10-story housing project, was demolished in three phases over three years. Despite the buildings having identical designs, each phase was handled differently by the demolition teams. Engineered Demolition, Inc. carried out the implosions in the summer of 1999.

Photo courtesy ImplosionWorld.com

The Hayes Homes in Newark, N.J., a 10-story housing project, was demolished in three phases over three years. Despite the buildings having identical designs, each phase was handled differently by the demolition teams. Engineered Demolition, Inc. carried out the implosions in the summer of 1999.

Photo courtesy ImplosionWorld.comBrent Blanchard, an implosion specialist from

Typically, demolition experts detonate the main support columns on the lower floors first, followed by some upper floors. For instance, in a 20-story building, they might target the first, second, 12th, and 15th floors. While lower-floor explosions usually suffice to bring the building down, detonating upper-floor columns helps break the debris into smaller pieces, simplifying cleanup.

After determining the implosion setup, the next step is preparing the building. In the following section, we'll explore the pre-detonation preparations and how explosives are rigged for a precisely timed demolition.

Technically, an implosion occurs when something collapses inward due to external atmospheric pressure exceeding internal pressure. For example, removing air from a glass tube could cause it to implode.

Building implosions aren't true implosions—gravity, not atmospheric pressure, causes the collapse. However, the term is commonly used for this type of demolition. In this article, we use the term in this context.

Detonators and Dynamite

The Frank Leux Building in Birmingham, Ala., was demolished by Engineered Demolition, Inc. in the spring of 1997.

Photo courtesy ImplosionWorld.com

The Frank Leux Building in Birmingham, Ala., was demolished by Engineered Demolition, Inc. in the spring of 1997.

Photo courtesy ImplosionWorld.comIn the previous section, we explored how demolition experts plan a building implosion. Once the collapse strategy is finalized, the building must be prepared. The initial step, often started before the site is fully surveyed, involves clearing debris. Next, destruction crews remove non-load-bearing walls to ensure a cleaner collapse. Leaving these walls intact would stiffen the structure, complicating the implosion. Crews may also weaken support columns using sledgehammers or steel-cutters to facilitate easier collapse.

After preparation, blasters begin loading columns with explosives. Different materials require different explosives, with quantities determined by material thickness. For concrete columns, traditional dynamite or similar explosives are used. Dynamite consists of absorbent material soaked in highly combustible chemicals. When ignited, it burns rapidly, producing a large volume of gas that expands quickly, exerting immense pressure (up to 600 tons per square inch). Blasters insert this explosive into bore holes drilled into the columns. Upon ignition, the shock wave shatters the concrete into small pieces.

Demolishing steel columns is more challenging due to their strength. For steel structures, blasters often use RDX, a high-speed explosive that expands at up to 27,000 feet per second (8,230 meters per second). Instead of disintegrating the column, RDX slices through the steel, splitting it in half. Additionally, dynamite may be used on one side of the column to direct its fall.

Concrete columns (left) are shattered using conventional dynamite or similar explosives, while steel columns (right) are cut in half with RDX, a high-velocity explosive.

Photo courtesy ImplosionWorld.com

Concrete columns (left) are shattered using conventional dynamite or similar explosives, while steel columns (right) are cut in half with RDX, a high-velocity explosive.

Photo courtesy ImplosionWorld.comTo detonate RDX and dynamite, a significant shock is required. In demolition, this is achieved with a blasting cap, which contains a small amount of explosive material (the primer charge) connected to a fuse. Traditional fuses consist of a cord filled with explosive material. When ignited, the flame travels along the cord to the detonator, triggering the primary charge.

Blasting caps act as the catalyst to ignite the explosives placed in support columns.

Photo courtesy ImplosionWorld.com

Blasting caps act as the catalyst to ignite the explosives placed in support columns.

Photo courtesy ImplosionWorld.comModern demolition often employs electrical detonators instead of traditional fuses. These detonators use a lead line, an electrical wire coated with explosive material at one end. When current flows through the wire, resistance heats it, igniting the explosive coating and setting off the primer charge, which then triggers the main explosives.

Columns are packed with explosives and connected to blasting caps and fuses.

Photo courtesy ImplosionWorld.com

Columns are packed with explosives and connected to blasting caps and fuses.

Photo courtesy ImplosionWorld.comTo manage the explosion sequence, blasters use delay mechanisms, which consist of slow-burning material placed between the fuse and the primer charge. By adjusting the length of this material, they control the timing of each explosion. The fuse length also plays a role, as longer fuses take more time to ignite. These timing tools allow blasters to precisely orchestrate the order of detonations.

Blasters calculate the amount of explosives needed based on their experience and input from the building's architects and engineers. However, they don't rely solely on this data. To ensure accuracy, they conduct test blasts on a few columns, shielding them for safety. By experimenting with different explosive quantities, they determine the minimum charge required to demolish the columns effectively. This approach minimizes debris and reduces the risk of damaging nearby structures.

A test blast is conducted on a concrete column at the RCA Victor Complex in Camden, N.J. The building was demolished in the summer of 1997.

Photo courtesy ImplosionWorld.com

A test blast is conducted on a concrete column at the RCA Victor Complex in Camden, N.J. The building was demolished in the summer of 1997.

Photo courtesy ImplosionWorld.comTo further control debris, blasters often wrap columns in chain-link fencing and geotextile fabric. The fencing prevents large concrete chunks from scattering, while the fabric catches smaller fragments. Additionally, floors rigged with explosives may be wrapped in fabric to contain any escaping debris. Surrounding structures are also covered to shield them from flying debris and the force of the explosions.

Once everything is prepared, the implosion can begin. In the next section, we'll explore the final steps blasters take before the implosion, witness the event itself, and examine potential issues that can arise during explosive demolition. We'll also see how blasters assess the project after completion.

Brent Blanchard, an implosion expert at Protec Documentation Services, often hears the same question from enthusiasts: "How do I become a demolition expert?" Blanchard explains that there are no formal schools or programs for blasting. The only way to learn is through hands-on experience. Aspiring blasters typically work with established companies to master the field before deciding to stay or start their own firms.

Clients are naturally cautious about implosions and prefer hiring companies with proven track records. This makes it challenging for new firms to secure major projects. Most large-scale implosions are handled by around 20 well-known companies, where skills are often passed down through generations, creating a legacy of expertise.

The Big Bang

Click here to watch a video of the Holly Street Development, demolished in 2001 by Controlled Demolition Group, Ltd..

Video courtesy ImplosionWorld.com

Click here to watch a video of the Holly Street Development, demolished in 2001 by Controlled Demolition Group, Ltd..

Video courtesy ImplosionWorld.comIn previous sections, we explored the steps blasters take to prepare a building for implosion. Beyond these preparations, they must also reassure local authorities and businesses that nearby structures will remain unharmed. Demonstrating past successes is the most effective way to ease concerns.

Two towers in the Holly Street Development in London, England, were demolished in March 2001. This posed a significant challenge for Controlled Demolition Group, Ltd.. One tower had to be carefully rigged to fall away from a gas line, while the other had to collapse precisely into its footprint to avoid damaging adjacent buildings. The demolition was executed flawlessly, with no harm to the gas lines or nearby structures.

To assist blasters, a demolition company might hire an independent consulting firm like Protec Documentation Services. Protec uses portable seismographs to monitor ground vibrations and air-blasts during implosions. Brent Blanchard, an operations manager, explains that they also inspect nearby structures beforehand to evaluate potential damage claims. Additionally, Protec records the implosion from multiple angles to provide a clear record of events. Using data from past implosions, their engineers can predict the vibration levels a specific demolition might produce.

After pre-weakening the structure and loading the explosives, final preparations begin. Blasters conduct a last check of the explosives and ensure the area is completely clear. Despite the dangers, some enthusiasts attempt to bypass barriers for a closer view. Given the scale of destruction, it's crucial that all spectators remain at a safe distance, calculated based on the building's size and the amount of explosives used.

Occasionally, blasters miscalculate the range of debris or the amount of explosives needed. Overestimating can result in an unnecessarily powerful blast, while underestimating or failed detonations may leave the structure partially standing. In such cases, excavators and wrecking balls are used to complete the job. These incidents are rare, as safety is the top priority, and blasters are highly skilled at predicting implosion outcomes.

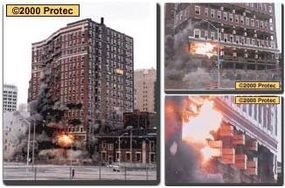

The Wolverine Hotel in Detroit, Mich., was demolished in early 1997 by Engineered Demolition, Inc.

Photo courtesy ImplosionWorld.com

The Wolverine Hotel in Detroit, Mich., was demolished in early 1997 by Engineered Demolition, Inc.

Photo courtesy ImplosionWorld.comOnce the area is secure, blasters move to the detonator controls and start the countdown. They may sound sirens at 10-minute, five-minute, and one-minute intervals to alert everyone. For electrical detonators, a controller with "charge" and "fire" buttons is used. Near the countdown's end, the "charge" button is pressed and held until an indicator light activates, building the necessary electrical charge. When the countdown finishes, the "fire" button is pressed (while still holding "charge"), releasing the charge to ignite the blasting caps.

Two types of blasting machines: a traditional rack-bar and a modern electronic control box

Photo courtesy ImplosionWorld.com

Two types of blasting machines: a traditional rack-bar and a modern electronic control box

Photo courtesy ImplosionWorld.comThe implosion itself typically lasts just a few seconds. For many spectators, the sheer speed of the collapse is the most astonishing part. How can a structure that took months or even years to build, and endured decades of weather, crumble into rubble as effortlessly as a sandcastle?

After the blast, a dust cloud spreads around the wreckage, surrounding nearby onlookers. While this cloud can be bothersome for residents near the site, blasters argue it’s less disruptive than the prolonged dust from non-explosive demolition. Traditional methods, using sledgehammers and wrecking balls, can take weeks or months, generating continuous dust. In contrast, implosions produce a single, concentrated dust cloud that dissipates quickly, allowing allergy-sensitive residents to avoid prolonged exposure.

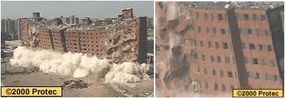

The Scudder Homes in Newark, N.J., demolished by Engineered Demolition, Inc. in the summer of 1996

Photo courtesy ImplosionWorld.com

The Scudder Homes in Newark, N.J., demolished by Engineered Demolition, Inc. in the summer of 1996

Photo courtesy ImplosionWorld.comOnce the dust settles, blasters inspect the site and review footage to ensure everything went as planned. They verify that all explosives detonated and remove any unexploded charges. If a consulting team was present, vibration and air blast data are also analyzed. Experienced blasters usually achieve the desired results, with minimal damage to nearby structures, often limited to a few broken windows. Any issues are noted and addressed in future projects, allowing the art and science of implosion to continually improve.