Explore the Grail Engine. View additional images of engines.

Courtesy of Grail Engine Technologies

Explore the Grail Engine. View additional images of engines.

Courtesy of Grail Engine TechnologiesImagine being told that in the future, your car could feature a single-cylinder engine with 100 horsepower, achieving 100 miles per gallon (42.5 kilometers per liter), and capable of running on any fuel type.

You might assume this is a scenario straight out of a science fiction movie or a distant concept far from becoming a reality.

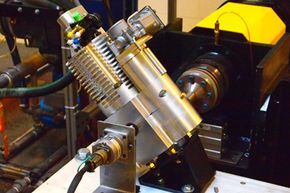

Matthew Riley, CEO and chief research scientist at Kansas-based Grail Engine Technologies, disagrees. He claims that the company's two-stroke Grail Engine could be available in consumer vehicles within two to five years. After three years of development, the company unveiled its first functional prototype in February 2012, attracting interest from major automakers like Honda and Ford.

According to Riley, the Grail Engine could be 50 percent less expensive to manufacture while delivering 30 percent improved fuel efficiency compared to existing engines. It is also versatile in terms of fuel compatibility and has a broad range of potential uses. Additionally, it avoids the pollution and reliability issues commonly associated with most two-stroke engines.

"This will revolutionize how things operate," said Riley, a scientist with over two decades of experience in experimental engine development. "The concept stems from the belief that there must be a more efficient way to design two-stroke engines due to their superior performance."

What sets the Grail Engine apart? Surprisingly, it doesn’t depend on a single groundbreaking technology. Instead, it integrates a range of advanced, modern engine technologies into one cohesive system. "It’s all established technology that has been utilized before," Riley explained.

At its core, the Grail Engine is a highly advanced two-stroke engine that employs forced induction, direct injection, and other innovations to achieve remarkable power and efficiency. It also introduces a novel concept the company refers to as "semi-homogeneous charged compression ignition," which we’ll explore in more detail shortly.

This article delves into the workings of the Grail Engine and examines its potential applications in the near future.

The Basics

To grasp the Grail Engine's functionality, it's essential to first outline the foundational principles that underpin its design.

Two-Stroke Engine: The Grail Engine operates as a two-stroke engine, differing from the more prevalent four-stroke engines found in most cars and motorcycles. A four-stroke engine undergoes four distinct phases in the combustion process: intake, compression, ignition, and exhaust.

In contrast, a two-stroke engine consolidates these phases into two steps. Intake and exhaust occur simultaneously, as do compression and ignition. While two-stroke engines are lighter and more powerful, they are less fuel-efficient, prone to frequent breakdowns, and emit significant exhaust gas due to the mixing of oil and fuel during combustion. This is why they are typically limited to small recreational vehicles and yard tools.

Direct Injection: Direct Injection (DI) is a cutting-edge engine technology gaining popularity in performance engines and increasingly in standard vehicles. In DI engines, fuel is injected directly into the combustion chamber instead of mixing with air in a separate manifold. This ensures a more uniform and efficient burn of the air-fuel mixture, leading to enhanced power and improved fuel economy.

Forced Induction: Even if the term forced induction is unfamiliar, you’ve likely heard of superchargers or turbochargers. Both technologies serve the same purpose: forcing additional air into the engine to create a hotter, more intense burn, thereby generating more power. The Grail Engine employs a distinctive form of forced induction, which we’ll explore shortly.

Forced Semi-Homogeneous Charged Compression Ignition: Referred to as FS-HCCI, this is a technology automakers have pursued for years, according to Riley. This method compresses air and fuel to near-combustion levels without requiring a spark (similar to diesel engines). When ignition occurs, the entire air-fuel mixture burns simultaneously, significantly improving efficiency. This results in greater power and superior fuel economy [source: Green Car Congress].

Grail Engine Design

The Grail Engine

Courtesy of Grail Engine Technologies

The Grail Engine

Courtesy of Grail Engine TechnologiesWith a compact size of just 500 cubic centimeters, the Grail Engine is significantly smaller — roughly one-fourth the size of a standard engine found in an economy car.

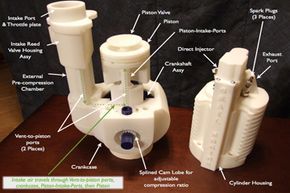

At first glance, the prototype resembles a typical two-stroke engine, but a closer look reveals a large, upward-facing intake valve positioned at the center of the piston. This feature plays a crucial role, as the Grail Engine leverages air pressure far more effectively than conventional internal combustion engines. The engine's components include:

- A cylinder and a piston

- A single exhaust valve located at the cylinder's top, which expels exhaust gases post-combustion

- Three spark plugs positioned at the cylinder's top, responsible for generating the ignition spark (unlike most car engines, which use one spark plug per cylinder)

- A "pre-compression chamber" containing a reed valve, ensuring one-way airflow into the engine (a common feature in two-stroke engines)

- A single intake valve inside the piston, drawing in air and fuel

- Two vent-to-piston ports and two piston-intake ports

- A compact crankcase that converts piston motion into wheel motion

[Source: Grail Engine Technologies]

Grail Engine Functions

The Grail Engine

Courtesy of Grail Engine Technologies

The Grail Engine

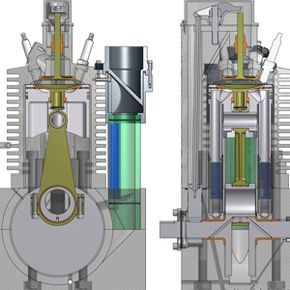

Courtesy of Grail Engine TechnologiesSimilar to any internal combustion engine, the Grail Engine ignites a mixture of air and fuel, harnessing the resulting explosion to move a piston up and down, generating motion. However, the Grail Engine’s approach to this process is what sets it apart.

As the piston moves upward, it creates a vacuum beneath it, drawing fresh air through a one-way reed valve. This air then fills three chambers: the pre-compression chamber, the vent-to-piston ports, and the piston-intake ports.

Once the piston reaches the peak of its movement, ignition is triggered by the three spark plugs. This drives the piston downward, compressing the air that has been trapped in the crankcase up to this stage.

When the piston hits bottom dead center, the exhaust valve opens, allowing exhaust gases to exit the cylinder. Simultaneously, compressed air enters the combustion chamber through the vent-to-piston and piston-intake ports via a one-way valve embedded in the piston.

Compressed fresh air swirls upward in a vortex-like motion, clearing the cylinder of exhaust gases and filling it with fresh air. After the exhaust valve closes, fuel is direct injected and mixed in the chamber. The air-fuel mixture is then compressed and ignited by the three spark plugs, causing an explosion that drives the piston down and initiates the next cycle.

It may seem straightforward, but the Grail Engine, while resembling a standard two-stroke engine, places a much greater emphasis on compressed air. Unique aspects include the swirl mixing of compressed air and fuel, which Riley claims creates the most efficient air-fuel atomization for optimal combustion. Additionally, the engine’s design forces compressed air into the combustion chamber while simultaneously air-cooling the piston’s top, reducing emissions—a feature Riley says no other engine possesses.

The three spark plugs produce a rapid series of explosions, enabling "forced semi-homogeneous charged compression ignition" (FS-HCCI). This process compresses air and fuel to near-combustion levels without requiring a spark. When combustion occurs, all remaining fuel in the chamber ignites simultaneously, significantly improving efficiency. This leads to increased power and better fuel economy [sources: Green Car Congress, Wojdyla].

Benefits of Grail Engines

The Grail Engine

Courtesy of Grail Engine Technologies

The Grail Engine

Courtesy of Grail Engine TechnologiesThe Grail Engine boasts a highly efficient internal combustion process. It is lightweight, cost-effective, and delivers impressive power relative to its size. As previously mentioned, the 500 cc prototype generates 100 horsepower while achieving 100 miles per gallon (42.5 kilometers per liter). But what additional advantages does it offer?

According to Riley, the Grail Engine overcomes many of the typical drawbacks associated with conventional two-stroke engines. For instance, oil and fuel do not mix, eliminating smoke issues. Additionally, it operates quietly and with minimal vibrations.

Thanks to the constant flow of fresh, compressed air, the engine maintains optimal cooling. This consistent cooling of the combustion chamber is crucial for enabling FS-HCCI, as Riley explained. This not only enhances thermal efficiency but also reduces nitrogen oxide emissions. Moreover, the Grail Engine’s modular design allows multiple units to be combined, creating a multi-cylinder configuration [source: Wojdyla].

As Riley often remarks, "Wait — there’s more." The Grail Engine is engineered to operate on nearly any fuel type, including gasoline, propane, diesel, and natural gas. It can even store multiple fuel types simultaneously in separate tanks. This versatility is made possible by an onboard computer that dynamically adjusts the engine’s compression ratio, allowing seamless transitions between different fuels.

Additionally, its design addresses the hydrogen contamination issues prevalent in fuel cell vehicles, making hydrogen a more viable fuel option. "This redefines the potential of fuel cells," Riley stated.

Grail Engine Applications

We’ve already highlighted the Grail Engine’s impressive power, superior fuel economy, and efficiency compared to traditional two-stroke engines. But where can it be utilized? According to Riley, the possibilities are nearly limitless.

"It has potential applications across various sectors, from automobiles to aircraft, as well as recreational and industrial engines," he explained. "There’s significant interest from multiple industries."

In addition to car manufacturers, Riley mentioned that the Department of Defense has shown interest, though he couldn’t disclose specific details about the project. He also noted that the engine could serve as an excellent helicopter engine.

While the current prototype is 500 cubic centimeters, the team is developing larger versions, including 1,000 cc and 2.5-liter models.

Riley emphasized that his team is driven by a mission to improve the world, not by financial gain. Their aim is to collaborate with existing car manufacturers to produce licensed versions of the technology. He believes this innovation could contribute to a more sustainable future. "Our goal isn’t to disrupt industries," Riley said. "We want to assist people and make a positive impact on the world."