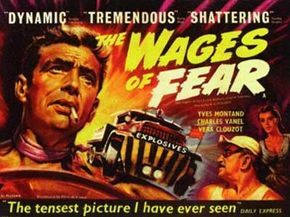

Inspired by Georges Arnaud's novel, "Wages of Fear" offers a gripping perspective on the fragility of a smooth journey.

Image courtesy Amazon.com

Inspired by Georges Arnaud's novel, "Wages of Fear" offers a gripping perspective on the fragility of a smooth journey.

Image courtesy Amazon.comThe 1953 French thriller "The Wages of Fear" follows a group of men undertaking a perilous mission: moving volatile nitroglycerine through treacherous jungle terrain to stop an oil well fire. The film immerses viewers in the tension, making them feel every jolt and bump, as a single misstep could lead to catastrophic consequences.

While your towing tasks may not be as perilous, ensuring a smooth ride is still crucial. Whether transporting animals or delicate goods, the right tires and suspension systems are key. These systems, equipped with springs and shock absorbers, minimize road impact for a comfortable journey. Dive deeper into the topic with How Car Suspensions Work.

This is where suspension bolts come into play. These sturdy metal rods feature spiral grooves on one or both ends, similar to screws. This design enables them to pass through metal plates or vehicle components and securely fasten into nuts on the opposite side, effectively linking the suspension to the vehicle or wheel.

In this article, we’ll explore the various types of suspension bolts and their applications. Who knows? If you ever find yourself stuck in a remote South American town, this knowledge might just save your life.

Types of Suspension Bolts

Shackle bolts secure shackle links, ensuring a stable connection between the suspension system and the vehicle or trailer.

Image courtesy 4Crawler.com

Shackle bolts secure shackle links, ensuring a stable connection between the suspension system and the vehicle or trailer.

Image courtesy 4Crawler.comWhile attaching wheels to a car body might seem straightforward with toy building blocks, linking a real suspension system to a vehicle or trailer is far more complex. Various connections require different bolts. Below, we’ll explore the primary types of suspension bolts commonly found in suspension systems.

Shackle bolts: Shackle links are a method used by automakers to connect the vehicle body to the wheels. As shown in the adjacent image, one end of each shackle link attaches to the vehicle, while the other connects to the suspension. Nuts are tightened over the ends to secure the bolts, and grease ensures smooth movement.

U-bolts: These U-shaped bolts wrap around a vehicle's axle, with their ends threaded into nuts on the opposite side of a metal plate. This setup is used to firmly attach bow-shaped leaf springs to the axle. For more details, check out How Leaf Springs Work.

Spring eyebolts: While U-bolts secure the middle of a leaf spring to the axle, eyebolts connect the spring's ends to the vehicle or trailer frame. These bolts fit through the circular eyes at each end of the leaf spring and into corresponding hanger holes on the frame.

Spline bolts: Ideal for fastening without rotation, spline bolts feature teeth along their sides to lock them in place. They are commonly used to secure shock absorbers.

Equalizer bolts: Equalizer hitches balance the load between the trailer tongue and the towing vehicle, ensuring even weight distribution. Equalizer bolts fasten these hitches, with some designs including a cotter pin to prevent the nut from loosening.

On the next page, we’ll dive into the practical use of suspension bolts.

Using Suspension Bolts

These straightforward U-bolts are crucial for securing vehicles and trailers.

Image courtesy Amazon.com

These straightforward U-bolts are crucial for securing vehicles and trailers.

Image courtesy Amazon.comIf you’re using suspension bolts to assemble your suspension system and link it to the vehicle or trailer, you’re using them as intended. However, remember that specific bolts are tailored for particular parts of the suspension. When replacing a bolt, ensure you have the correct size and type.

If you choose to replace suspension bolts yourself rather than visiting a professional garage, take necessary precautions. Before disassembling any part of the suspension system, securely lift the vehicle or trailer body off the ground, similar to changing a flat tire. Avoid placing jacks or supports on the suspension system itself. Elevate the heaviest part (the body) to safely work on the lighter suspension components.

Bolts that need to rotate, like shackle bolts, require greasing for smooth movement. While many modern vehicles have sealed components, older models and trailers may need periodic lubrication through grease zerks (also called grease nipples or fittings). These small openings allow a grease gun to apply the manufacturer-recommended lubricant, ensuring proper maintenance.