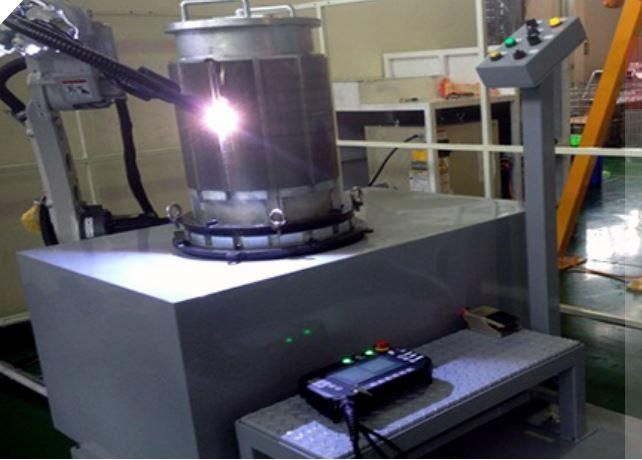

1. OTC DAIHEN FD-B4L Welding Robot

OTC DAIHEN FD-B4L Welding Robot features a unique design with its welding cable integrated inside the arm, offering enhanced flexibility and the ability to weld in tight spaces with minimal maintenance. Its performance is superior to competitors, improving both efficiency and productivity.

This robot also boosts instantaneous speed by up to 40%, reducing operational time compared to other robots. It operates smoothly, ensuring precise weld start points and optimal arc initiation on all materials. The need for maintenance is significantly reduced thanks to integrated standard modules.

Technical Specifications:

- FD-B4L Arm:

- Number of axes: 6

- Reach: 2.008m

- Payload: 4kg

- Repeatability: ±0.08mm

- Motor system: AC servo motor

- Weight: 277kg

- Mounting options: Floor, ceiling, or wall-mounted

- FD 11 Control Cabinet (100% new):

- Input voltage: 200V or 220V (3-phase)

- Control system: AC servo motor

- Number of axes controlled: Up to 54

- Memory capacity: 160,000 commands

- Program count: 9,999

- USB memory expansion

- Operating temperature: 0 to 45°C

- Humidity: 20 to 80 RH non-condensing

- PLC software: Teach Pendant programming

Currently, the OTC DAIHEN FD-B4L welding robot is distributed, installed, and assembled officially by HUNG LONG INDUSTRIAL EQUIPMENT CO., LTD. Interested customers can visit the company directly or access the website for more information on this high-quality product.

Contact Information:

Address: Skylight Building Office, Ha Phong Urban Area, Tien Phong, Me Linh, Hanoi

Factory: Trang Viet, Me Linh, Hanoi

Phone: 0984 884 980 & 0986 078 980

Fax: 028 6254 9068

Email: [email protected]

Website: www.laserviet.vn / robotviet.com.vn

Reference Link: http://laserviet.vn/san-pham/robot-otc-daihen-fdb4l-91.htm

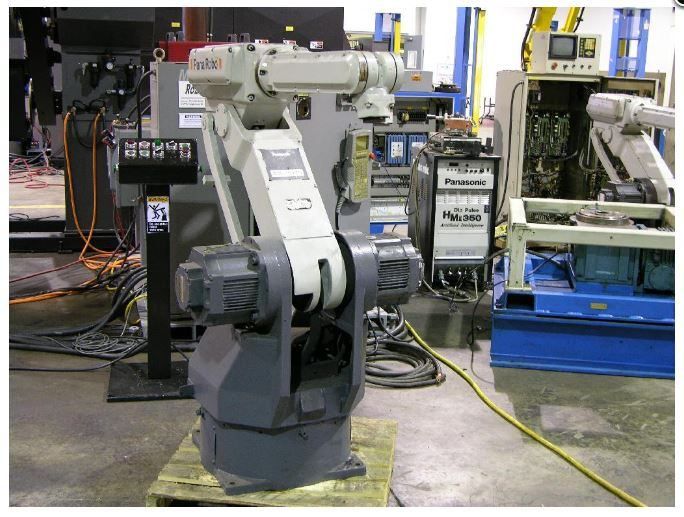

2. Panasonic AW8010 Welding Robot

This Panasonic welding robot is designed for both durability and flexibility. With a reach of 1.615mm, it is suitable for various applications across different products. The Panasonic AW8010 Welding Robot can be integrated with track systems, turntables, and dual or triple welding tables to improve production efficiency, enhance flexibility, and accommodate a wide range of products.

The welding arm features 6-axis motion, making it perfect for welding in tight spaces. The Panasonic inverter welder connects to the robot through an interface, ensuring clean welds with minimal spatter at a high welding speed. It offers great value and is widely used and effective in Vietnam.

Technical Specifications:

- Panasonic AW 8010 Arm:

- Automates programming and welding processes

- Programs welding paths and controls the robot for automatic welding

- 6-axis movement capability for full flexibility

- Performance:

- Reach: 1.335m

- Maximum payload: 6kg

- Rotation range: ±180°

- Upper arm: +150°; -90°

- Lower arm, horizontal rotation: +60°; -70°

- Upper rotation range: +90°; -80°

- Wrist rotation: ±200°

- Basic forward bending: ±140°

- Wrist twist: ±185°

- Working Speed:

- Rotation: 2.62 rad/s; 1500/s

- Upper arm: 2.71 rad/s; 1500/s

- Lower arm: 2.71 rad/s; 1500/s

- Wrist rotation: 5.23 rad/s; 2600/s

- Forward bending: 5.23 rad/s; 2600/s

- Wrist twist: 6.98 rad/s; 4000/s

- Braking system: All axes

- Mounting options: Floor, wall, or ceiling-mounted

- Repeatability accuracy: ±0.1mm

- Operating temperature: 0 ~ 45°C

- Safety and self-protection: Overvoltage protection, collision prevention

- Weight: 350kg

Currently, the Panasonic AW8010 Welding Robot is officially distributed, installed, and assembled by HUNG LONG INDUSTRIAL EQUIPMENT CO., LTD. Customers interested in this high-quality welding robot can visit the company directly or explore the website for more information.

Contact Information:

Address: Skylight Building Office, Ha Phong Urban Area, Tien Phong, Me Linh, Hanoi

Factory: Trang Viet, Me Linh, Hanoi

Phone: 0984 884 980 & 0986 078 980

Fax: 028 6254 9068

Email: [email protected]

Website: www.laserviet.vn / robotviet.com.vn

Reference Link: http://laserviet.vn/san-pham/robot-han-panasonic-aw8010-81.htm

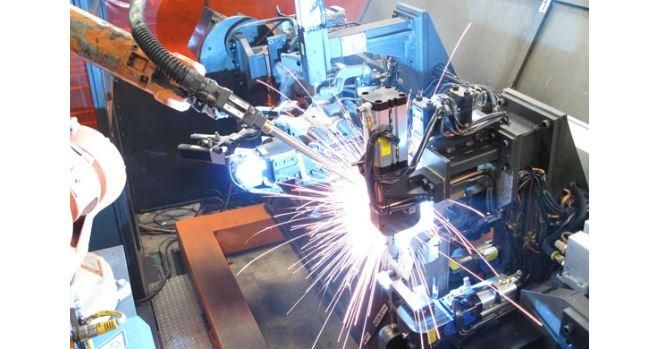

3. OTC Daihen Almega EX V6-V6L Welding Robot

The OTC Daihen Almega EX V6-V6L is a long-reach welding robot with a 2.006m reach, suitable for high-speed and precise welding applications. Its compact and efficient design makes it the best solution for welding tasks.

This OTC robot's arm moves 20% faster than others in the market. With six-axis free movement and synchronized motion, it ensures smooth operation with automatic vibration reduction at high speeds. The highly sensitive collision sensor guarantees safe performance.

Specifications:

- Almega EX-V6 Arm

- 6-axis: (axes)

- Reach: 1.402m

- Payload: 6kg

- Repeatability: ±0.08mm

- Motor system: AC servo motor

- Weight: 155kg

- Mounting options: Floor, ceiling, or wall-mounted

- Working range:

- Axis 1: ±170°

- Axis 2: +155°

- Axis 3: ±170°

- Axis 4: ±180°

- Axis 5: ±500°

- Axis 6: ±360°

- Movement speed:

- Axis 1: 100°/s (2.62 rad/s)

- Axis 2: 160°/s (2.79 rad/s)

- Axis 3: 170°/s (2.97 rad/s)

- Axis 4: 340°/s (5.93 rad/s)

- Axis 5: 340°/s (5.93 rad/s)

- Axis 6: 520°/s (9.08 rad/s)

- EX Controller:

- Input voltage: 200V or 220V (3-phase)

- Control system: AC servo motor

- Extended memory: Compact Flash card

- I/O relays: 32 in/out

- PLC software: Program via Teach Pendant

- Almega Auto II Welder:

- Input power: 3-phase/200/220VAC/50/60Hz

- Maximum power consumption: 28.5KVA/21.3Kw

- Welding current range: 40A to 350A

- Efficiency: 60%

- Weight: 55kg

- Accessories:

- MIG welding gun for robots, wire feeder, and support fixture

- Safety operation start box

- Signal cable, welding cable

- Robot control panel

- 15 kVA transformer (brand new)

Currently, the OTC Daihen Almega EX V6-V6L Welding Robot is officially distributed, installed, and assembled by HUNG LONG INDUSTRIAL EQUIPMENT CO., LTD. Interested customers can visit the company directly or explore the website for more information.

Contact Information:

Address: Skylight Building Office, Ha Phong Urban Area, Tien Phong, Me Linh, Hanoi

Factory: Trang Viet, Me Linh, Hanoi

Phone: 0984 884 980 & 0986 078 980

Fax: 028 6254 9068

Email: [email protected]

Website: www.laserviet.vn / robotviet.com.vn

4. Yaskawa Motoman HP6 Welding Robot

The Yaskawa Motoman HP6 welding robot is manufactured in Japan by Yaskawa Motoman. It offers six-axis free movement with synchronized motion and automatic vibration reduction for smooth high-speed operation. The highly sensitive collision sensor ensures safety during production operations.

Its high-precision wire feeding system is independent of temperature, tube length, or robot reach, ensuring stable welding quality in any position, even with complex welding paths. Standard 4-wheel design provides 1.5 times more wire feed capacity compared to the 2-roller type. The encoder feedback adjusts acceleration instantly for continuous precise welding.

Specifications:

- HP6 Arm

- Reach: 1.400m

- Payload: 6kg

- Repeatability: ±0.08mm

- Working range:

- Axis 1: ±170°

- Axis 2: +155° to -90°

- Axis 3: +250° to -175°

- Axis 4: ±180°

- Axis 5: +225° to -45°

- Axis 6: ±360°

- Movement speed:

- Axis 1: 150°/s (2.62 rad/s)

- Axis 2: 160°/s (2.79 rad/s)

- Axis 3: 170°/s (2.97 rad/s)

- Axis 4: 340°/s (5.93 rad/s)

- Axis 5: 340°/s (5.93 rad/s)

- Axis 6: 520°/s (9.08 rad/s)

- Safety features: Overpressure protection, collision protection for the arm

- Weight: 130kg

- NX100 Controller:

- Windows CE-based controller

- Touch-screen color display

- High-speed processor supports up to 4 robots and 36 external axes

- Memory: 60,000 steps, 10,000 instructions

- Easy Ethernet connection for computer control

- ARM (Advanced Robot Motion) mode for maximum speed and precision

- Meets ANSI/RIA R15.06-2009 safety standards

- Flexible control: Synchronous or independent operation

- Simultaneous multitasking reduces cycle times

- Modular design for easy maintenance

- Data storage via CF Card

- Control Panel:

- Color LCD touch screen

- Advanced functions for monitoring and maintenance

- 6.5-inch LCD display (640 x 480 pixels)

- 10,000 system instructions, no need for external PLC

- DPTD 350 Welding Power Source (new, manufactured in 2018):

- Input voltage: AC 380V, 3-phase, 50/60Hz

- Power: 18kVA (14kW)

- Maximum welding current: 350A

- Duty cycle: 100%

- Welding current range: 40-350A

- Welds steel and stainless steel

- Digital inverter welding machine

- Accessories:

- MIG welding gun for robots, wire feeder, and support fixture

- Safety operation start box

- Signal cables and welding cables

- Robot control panel

- 6kVA transformer (brand new)

Currently, the Yaskawa Motoman HP6 Welding Robot is officially distributed, installed, and assembled by HUNG LONG INDUSTRIAL EQUIPMENT CO., LTD. Interested customers can visit the company directly or explore the website for more information.

Contact Information:

Address: Skylight Building Office, Ha Phong Urban Area, Tien Phong, Me Linh, Hanoi

Factory: Trang Viet, Me Linh, Hanoi

Phone: 0984 884 980 & 0986 078 980

Fax: 028 6254 9068

Email: [email protected]

Website: www.laserviet.vn / robotviet.com.vn

5. Panasonic-008ALII Welding Robot

The Panasonic-008ALII welding robot is a high-performance six-axis robot. It's designed for automation applications like MIG and TIG welding, offering unmatched precision and high output performance. It also supports plasma cutting and material handling with advanced 64-bit RISC microprocessors, making it ideal for complex tasks.

Optimized speed and performance are guaranteed with its compact design and wide working arm. The VR-008 model comes with standard brakes on all six axes and a wrist design that provides excellent flexibility. The controller features a 4-inch display and a user-friendly interface powered by Microsoft Windows CE. The controller supports analog communication for welding applications.

Specifications:

- Reach: 1.335m

- Max Robot Payload: 6kg

- Capabilities:

- Automatic programming and welding operations

- Welding path programming and robot-controlled welding

- Free 6-axis movement

- Operational Range:

- Rotational angle: ±180°

- Upper arm: +150°; -90°

- Lower arm, horizontal rotation: +60°; -70°

- Upper joint rotation: +90°; -80°

- Wrist rotation: ±200°

- Basic front bending: ±140°

- Joint twisting: ±185°

- Working Speed:

- Rotational angle: 2.62 rad/s; 1500/s

- Upper arm: 2.71 rad/s; 1500/s

- Lower arm: 2.71 rad/s; 1500/s

- Wrist rotation: 5.23 rad/s; 2600/s

- Front bending: 5.23 rad/s; 2600/s

- Joint twisting: 6.98 rad/s; 4000/s

Currently, the Panasonic-008ALII Welding Robot is officially distributed, installed, and assembled by HUNG LONG INDUSTRIAL EQUIPMENT CO., LTD. Customers interested in this high-quality welding robot can visit the company or explore the website for more information.

Contact Information:

Address: Skylight Building Office, Ha Phong Urban Area, Tien Phong, Me Linh, Hanoi

Factory: Trang Viet, Me Linh, Hanoi

Phone: 0984 884 980 & 0986 078 980

Fax: 028 6254 9068

Email: [email protected]

Website: www.laserviet.vn / robotviet.com.vn

Reference Link: http://laserviet.vn/san-pham/robot-panasonic-vr008alii-83.htm