During the Industrial Revolution, the spinning mule dramatically accelerated cotton processing. mikroman6 / Getty Images

During the Industrial Revolution, the spinning mule dramatically accelerated cotton processing. mikroman6 / Getty ImagesAt the core of the Industrial Revolution, the textile industry experienced a significant shift with the introduction of the spinning mule. Created by Samuel Crompton and enhanced by Richard Roberts, this innovation was crucial in transforming textile production from cottage industries. This article explores the origins, functionality, and societal impacts of the spinning mule.

What Is a Spinning Mule?

The spinning mule represented a major leap forward compared to earlier inventions like the spinning jenny and the spinning wheel. Created by Samuel Crompton in 1779, this machine merged the strengths of both devices. It utilized the spinning jenny's multiple spindles and the spinning wheel's uninterrupted spinning process, leading to higher efficiency and the ability to produce superior-quality yarn.

Samuel Crompton's Spinning Mule

Samuel Crompton, a talented and inventive weaver from Lancashire, England, designed the spinning mule to overcome the shortcomings of earlier spinning methods.

By integrating the concepts behind James Hargreaves' spinning jenny and Richard Arkwright's water frame, Crompton engineered a device capable of spinning cotton thread with remarkable accuracy. This innovation enabled the production of stronger and finer yarns, significantly enhancing textile manufacturing.

Richard Roberts' Self-acting Spinning Mule

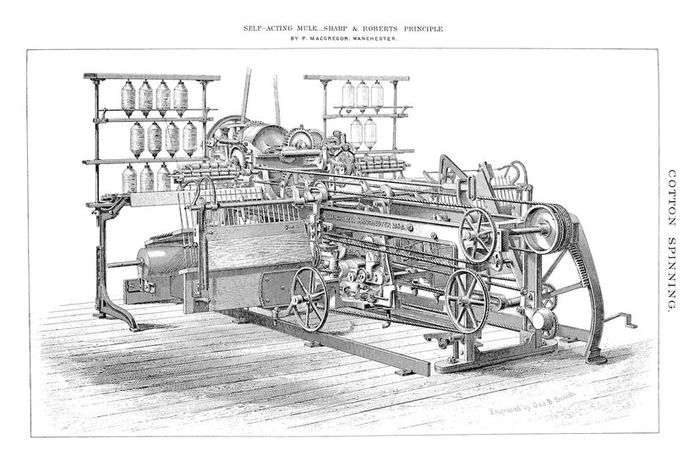

Expanding on Crompton's groundbreaking design, Richard Roberts, a renowned English engineer, unveiled the self-acting spinning mule in the 1820s. This advancement mechanized several tasks, reducing the reliance on human labor.

The self-acting mule incorporated a roller beam system, which provided enhanced precision in the spinning process and facilitated the creation of superior yarns at varying speeds.

Operating a Spinning Mule

Operating a spinning mule required the use of several essential parts. A mobile carriage, powered by a rotating main shaft, transported a set of spindles attached to the mule's structure. The draw stroke, an intermittent process, entailed stretching the roving (twisted fiber) and feeding it to the spindles.

While the carriage moved backward, the thread was spun, and once it returned to its starting position, the finished yarn was coiled onto bobbins. This repetitive cycle enabled a single worker to operate the spinning mule efficiently.

Socioeconomic Impact of the Spinning Mule

The spinning mule's influence on the textile sector and society cannot be overstated. It enabled the large-scale production of yarns and fabrics, paving the way for massive factories and the dawn of industrialization. Before its invention, textile manufacturing was largely confined to cottage industries, where manual machines restricted productivity. The spinning mule, capable of generating superior yarns in vast amounts, became a driving force behind the industry's evolution.

The swift expansion of textile mills, especially in cotton-producing areas like Lancashire, prompted workers to move from rural regions to urban centers. This demographic shift and the focus of labor in industrial zones played a key role in the development of thriving cities. Manchester, for instance, became a dominant force in textile manufacturing.

The original spinning mule — along with its enhanced versions — revolutionized the textile industry by producing finer, more durable yarns on a large scale. The resulting dependence on factories and mass production spurred socioeconomic changes that defined the Industrial Revolution.